Over the past several weeks, ZEV Technologies’ pistolsmiths have been taking a stock GLOCK 17 Gen 3 and converting it into a custom Soldier Systems Z17. They sent us this series of photos to illustrate what goes into the final assembly process but have continued to be coy about what the slide actually looks like. So far, we are as in the dark as our readers,

Final assembly begins….

1. The pistol is checked out by one of ZEV Technologies gunsmiths for final assembly, He starts by laying out all the parts and making sure he has everything to complete the install.

2. He installs the magwell insert that will accept the ZEV Slim magwell.

– The magwell functions as an attached funnel to aid in competition style speed reloads.

3. The ZEV Slim magwell is installed.

– ZEV All Aluminum Slim Magwell. Legal for IDPA, ESP competition.

4. The Fulcrum trigger is now installed into the Glock™ frame

– The trigger was adjusted for Pre-Travel and Over-Travel.

5. ZEV Extended magazine release is installed.

– The Mag Button is oversized so you can access it without shifting your grip but shaped in such a manner that it does not interfere with your shooting grip.

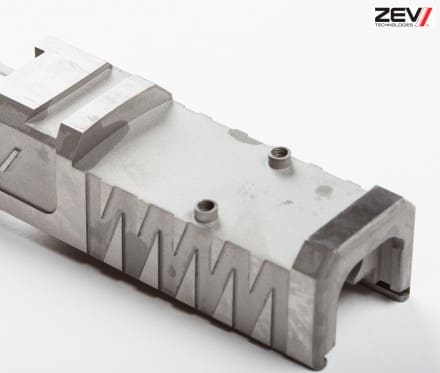

6. Here you see some of the components that will be installed on the ZEV slide.

-Skeletonized Firing Pin, extractor rod, extractor, Channel liner and RMR.

7. ZEV Skeletonized Firing Pin has its spring and spring cups installed.

-This firing pin has an extended tip for improved strike

8. ZEV co-witness rear sight is pushed onto the frame.

– These ZEV sights allow the shooter to still be able to aim in the unlikely event the RMR battery does not function.

9. Trijicon RMR is installed onto the slide.

– The RMR sight is the most rugged miniature red dot sight available.

10. ZEV uses blue Loctite to install the RMR mounting screws.

– This prevents the RMR screws from backing out.

11. The ZEV slide is lubricated before it is installed onto the frame.

– ZEV recommends you clean and re-lube your slide after 500 rounds.

12. The frame and slide are assembled together and sent off to ZEV’s QC department where they will not only be given a visual inspection but also test fired before being shipped out to the customer.

Next week, we’ll be in Southern California to visit the ZEV headquarters where we’ll get a chance to finally see the complete Z17.

To have your GLOCK tuned up by the pros at ZEV, visit www.zevtechnologies.com.