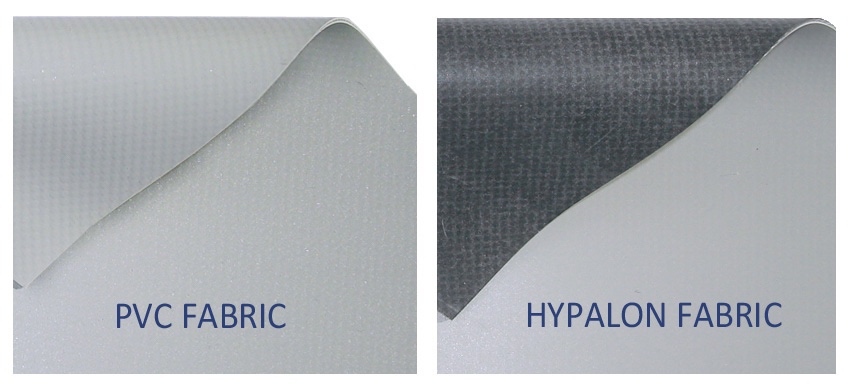

Knowing what you have is necessary before you can even diagnose a problem or figure out what kind of work your inflatable might need. You must first be informed that there are two different kinds of cloth available: PVC and Hypalon (CSM).

Due to the differences in their construction, each requires a unique approach to maintenance and repairs. As with so many maritime-related things, periodic checks of your boat will help you identify minor concerns before they turn into bigger ones. Like everything else, UV is the worst thing for PVC and Hypalon. Do a visual and rub your hands along the boat’s tubes to help find dry or cracked spots, “alligatoring”, but you will need to improve your UV protection.

To start your inspection, fill your spray bottle with liquid soap, pump the boat to specifications from the aft to the forward (drum tight), and then begin spraying. It will be more effective to set your spray nozzle to create a wide mist than a narrow jet. In both cases, make sure to soak the tubes thoroughly. Finding air bubbles is essential because they are a surefire indicator of leaks. Keep an eye out for valves, cones, and seams. Rarely are leaks cooperative enough to show up on a field of open tubes. Nope, they would much rather stand next to or even behind some fitting or label.

Check the cloth for wear, especially the tube tops. Where guys will sit with all their gear on, and it might rub holes or start to rub holes. They will eventually dry out and begin to leak. Check for wear on all the attachments and accessories. Some accessories will droop and chafe the tube fabric as the tubes deflate in colder conditions. Don’t forget to check the holders for the transom.

Look under the boat to inspect the bottom for wear, particularly to the areas around the transom and where strips connect it to the tubes. While you’re at it, grip the tube-to-hull strips directly to check for any fabric that may have come loose. Keep a close lookout for rot if your transom is made of wood.

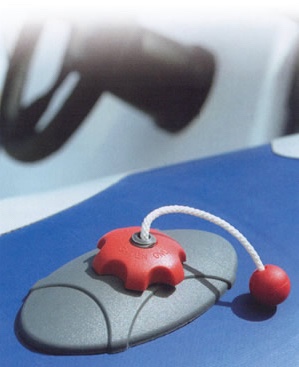

Lastly, examine all the valves. Are all the caps present? The “plungers” are they free to move? It’s okay to spray a little more of the soap mixture while you’re rummaging around to clear out any sand or other debris that may have started to gather.

Before putting the boats away, give your tubes a UV treatment in addition to routine checks. Use a manufacturer-recommended UV protectant. There are several goods available.

Spray the boat down after every use and give it a good cleaning before you stow it away. Salt away is a great product to help get all the salt off the boat. Never leave an inflatable in the sun to the recommended pressure after filling it. This is especially true for PVC boats with glued seams since you could stress the seams and produce leaks (or worse). On the other hand, buzzing around while the tubes are not inflated to the proper pressure will undoubtedly ruin those handy transom holders. This is due to the outboard’s vibration, which will cause the tubes to start pulling away from the transom if they aren’t pushed tightly against its sides. Inflatable air chambers are divided by internal baffles that keep them apart in the event of an accident-punctured chamber. These baffles also balance the air pressure throughout all the chambers’ connections.

Underway repair You should always keep the following supplies on board: a hand pump, duct tape, ClamSeal, and some beach balls.

It isn’t much you can do if a boat is punctured below the water line besides pumping air using a hand pump to reduce the air leak. You can buy a ClamSeal for quick emergency repairs in torn inflatables.

Duct tape can temporarily repair punctures inside the boat that is in easily accessible areas. Before applying duct tape, the area around the puncture should be cleansed with acetone to ensure a proper seal. After that, you can pump air into the boat to slow the escaping air, allowing you to land as soon as possible. If a hole gets ripped in the sponson before you put the ClamSeal on, you can set the beach ball in there and inflate it when it is in there, which will help make the sponson more stable. Then try and close the hole with tape or a ClamSeal. On a side note, you can also use flex seal tape or other products. The downside is getting all the adhesive off that spot to repair the hole, but that is a dry land problem.

Really should consider collecting these articles into a book.

Can’t beat Tyvek tape for in-situ repairs.

No mention at all of polyurethane, which is the material that a US military inflatable will most likely be made from?

CapnTroy,

Hypalon is like saying coke or Pepsi it is a trade make name for a type of polyurethane. Different boat makers use basically the same thing but under a different names. It’s all PVC or polyurethane. I just called it hypalon thats all. Sorry for the confusion