NFM Group and Cooneen Protection Ltd are proud to announce a landmark con-tract awarded by the French Ministry of Interior (MOI). The consortium, with NFM France SAS acting as the representative, alongside Cooneen Protection Ltd and NFM Production Sp. z o.o. has been selected to supply Individual Bulletproof Vests 2022 (GPB-I) and tactical vest for various French security forces.

NFM Group and Cooneen Protection Ltd take immense pride in being entrusted with the responsibility of providing state-of-the-art protective gear to France’s protectors. This achievement underscores our joint commitment to protecting those who safeguard French communities, and we are proud to contribute to their safety with our products.

The objective of the tender was to provide advanced protective gear for the Police Nationale, Gendarmerie Nationale, Gendarmerie Maritime, French Customs, Security and Defense Cooperation Directorate, and Penitentiary Administration.

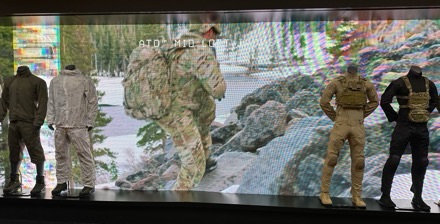

“The solution is a combination of protection and modularity thanks to the combination of products including the tactical vest: it is scalable which leads to being fully compliant with the users need to accomplish all aspects of their daily missions,” says Johann Le Cunff Managing Director NFM France.

The contract includes two lots:

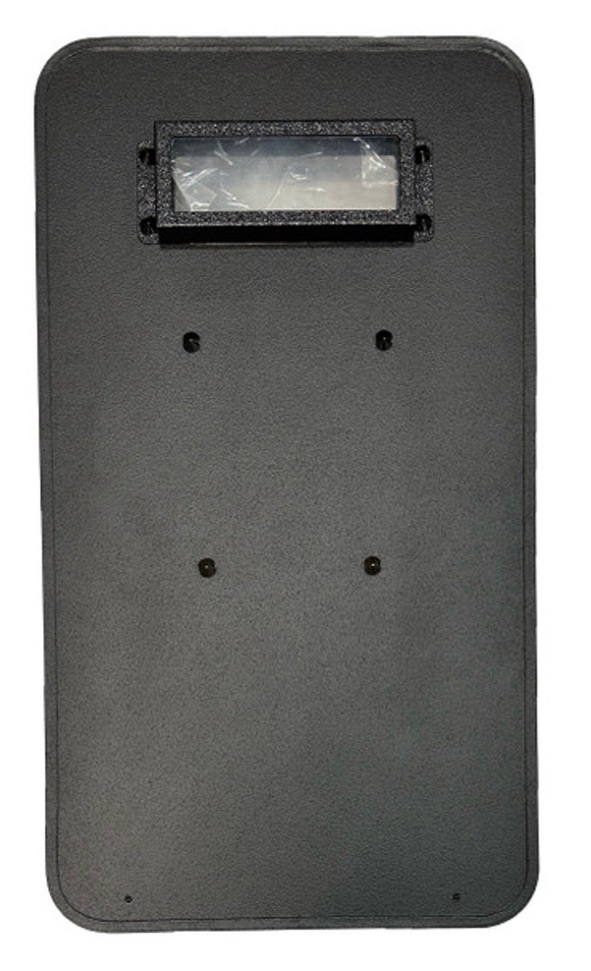

• Lot 1: Supply of a substantial quantity of Individual Bulletproof Vests and Tactical Vests, specifically designed for female operators.

• Lot 2: Supply of a significant number of Individual Bulletproof Vests and Tactical Vests, tailored for male operators.

The contract entails the delivery of up to 511,350 concealment vests and 415,596 tactical vests, catering to both male and female operators, over a period of four years.

The French Ministry of Interior (MOI) is at the forefront of a pioneering initiative within the protective gear sector, as demonstrated by their latest requirements set out in two distinct lots. It is particularly noteworthy that the French MOI has acknowledged and catered to the specific needs for female operators’ protective gear.

“In Lot 1, they have established an industry-leading approach by requesting a comprehensive range of body armour, distinctly designed for the unique requirements of female personnel. This progressive move reflects a profound understanding of the importance of comfort, fit, and protection in crafting gear for female end-users,” says Neville McIlwrath, Business Support Director at Cooneen Protection Ltd.

Lot 2, with its focus on male operators, ensures all personnel are equally outfitted with the highest standards of protection. Collectively, these lots underscore our dedication to fulfilling the diverse requirements of the French MOI, while showcasing our ability to innovate and adapt in a rapidly evolving industry.

“NFM and Cooneen are honoured to be part of this visionary development initiated by the French MOI. Our contribution to supplying these bespoke products not only meets a critical need but also marks our participation in a significant shift towards inclusivity and innovation in protective gear,” says Johann Le Cunff.

COMMITMENT TO QUALITY AND COLLABORATION

NFM France and Cooneen Protection Ltd. came together in a unique collaboration to provide an innovative and leading solution to the requirements of the French MOI. Both companies who are leaders in their respective markets worked closely together to develop and submit a winning solution to both female and male body armour requirements established by the French MOI.

“We were excited by the prospect of working with NFM in this unique arrangement. Our collaboration highlights the value of combining specialized skills and industry-leading expertise, and we look forward to the successful delivery of the contract,” says Neville McIlwrath.

NFM France’s commitment to local expertise is also clearly demonstrated through our strong engagement with leading French raw material suppliers.

“The contract highlights our strong collaboration with leading French raw material partners and underscores NFM’s commitment to incorporating first-choice French materials in our product composition, showcasing our pride working with top-tier local suppliers,” says Johann Le Cunff.

This contract with the French MOI marks a significant milestone for both NFM Group and Cooneen Protection.

“This partnership not only reinforces our commitment to supporting those who protect us but also strengthens NFM’s position as a major player in France,” says Johann Le Cunff.

“Cooneen are pleased to have been selected to continue to supply vital body armour products to the French MOI and look forward to further developing our position in the French market,” says Neville McIlwrath.