I have long planned to do a deeper dive into the history of Load Carriage in the U.S. Military with articles called “On the Road to ALICE” and “Beyond ALICE” sometime afterward. I did not prioritize it because…well, it was history and was not going to change. Of course, precursor parts of the series on the MOLLE era would focus on the Fighting Load Carrier (FLC) or “Flic” and the Tactical Assault Panel (TAP). However, I am pushing this contemporaneous chapter on the Airborne TAP (ABN-TAP) to the front because it is relevant to gear that is on the verge of entering the inventory and being worn by at least some Soldiers today and perhaps more in the future. In other words, I am doing it Star Wars or Pulp Fiction style – out of sequence. I know right now most people have more important things to be concerned about than tactical gear, but I hope this will – at least – be a welcome distraction for some.

I am going to assume that long time readers of SSD have a passing familiarity with the FLC and the TAP already. If not, a quick search on this site or the net can bring someone up to speed. When I started doing gear articles on SSD, someone asked my thoughts on the FLC. I had no opinion at the time. I had seen it in Iraq and Afghanistan but had never been issued any of the MOLLE I or II web gear or rucks. Since then I have acquired a number of samples and have experimented with them here on the Homestead. Therefore, I acknowledge that my observations and impressions are based on limited practical experience with the kit. Those of you with more “time in the harness” with these items should feel free to correct me or elaborate based on your own experiences.

There are several serious challenges with developing load carriage “systems” in the military. The big one is that load carriage is a low dollar line item in the DoD budget and is not ever going to be sexy or a high priority. Consequently, the Service involved generally makes little effort to articulate more than a vague concept of what they want because at the macro level load carriage is rarely considered mission essential. Notwithstanding the slideshows steeped in useless generalities and buzzwords, such as “it will support agile full spectrum operations” pseudo-guidance. While I was not in the room, I suspect that for the ABN-TAP the conversation was something like this, “Hey, the TAP is hard for paratroopers to rig to jump. OK, the ALICE web gear was easier to rig…so let’s splice the DNA and see if we get a racehorse or a camel.” I call the result a camel – it will get you there but is not the best ride. It certainly does seem that the focus was largely on adding one gimmick to the new system to make it more jumper friendly. Is that really all the ABN-TAP needs to do for troopers? Sure, old fashioned systems did interface a whole lot easier with a parachute harness. Still, should we not concentrate more on the functionality of the ABN-TAP during the vast majority of time a paratrooper is not wearing a parachute?

And, inevitably, we always seem to prefer fast and cheap over good. At some point, a senior leader gets frustrated because one or more components of “the system” are stuck in the process and it is all taking too long. He decides to go with it “as is.” Reasoning that other changes will be incorporated in the A1 and A2 versions. I think we are at that point with the ABN-TAP. That is not necessarily a bad decision. Much like soldiers have to eventually leave the schoolhouse and go to real units to complete their education, advancements in gear get to a point of diminishing returns if not sent out to the force for larger-scale evaluations and critiques. Unfortunately, that is also a glaring point of failure in the development process. When the item(s) is fielded, the team responsible has been habitually disbanded – leaving no dedicated point of contact or continuity of responsibility tasked to shepherd additional product improvements. It was true of ALICE and it is still true today.

Moreover, units will simply not spend time writing and sending in those hypothetical gear evaluations if not formally tasked to do so. Likewise, soldiers are not encouraged to provide input nor are they afforded any routine way to plug their individual feedback into the system. MOLLE I was only marginally improved by the Army into MOLLE II because soldier complaints went public after the initial operations in Afghanistan in 2001-02. As we know, those negative reports contributed to the USMC abandoning the MOLLE rucksack altogether. The result is that many soldiers – with good justification – simply accept the fact that some of their issue gear sucks and the chain of command does not care. Obviously, it would be better if that were not the case. Soldiers need confidence in their gear – from individual rifles to parachutes and tanks. They need even more confidence in their leaders.

Putting the Airborne transformer requirement aside, what should a good fighting load carriage system be able to do? First, it has to enhance – not interfere with – the soldier’s ability to shoot, move, and communicate effectively as part of a team. Specifically, it should be able to integrate reasonably well with issue IOTVs or plate carriers. It has to securely carry the items of the fighting load like magazines, grenades, IFAKs, etc. in such a way as to make those items readily accessible to a trooper under the stress of battle. With that in mind, the system also has to allow for the distribution and balance of that weight so that it is reasonably comfortable when worn – with or without armor as the mission may dictate – for days at a time. Finally, it helps if the system is as intuitive and uncomplicated as possible thereby allowing soldiers to individually configure, reconfigure, and field repair, the system quickly and as often as necessary. Does the ABN-TAP meet those criteria? No, it falls short in a number of areas.

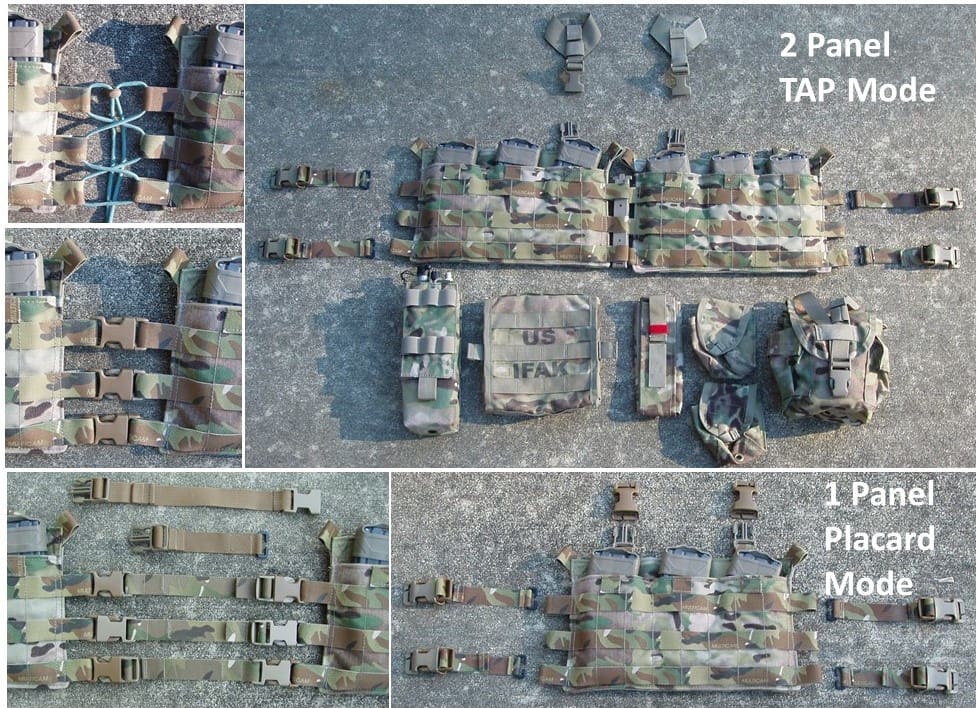

Let us look at the three samples I have of the ABN-TAP (shown above). The first one (bottom left) I believe is an original prototype. It is unmarked and I expect this was made in house at Natick. SSD has posted earlier news releases on the ABN-TAP. It has been noted that the mechanism for dropping the two front panels is the same as the First Spear JOKER chest harness. It is indeed the same – exactly the same. However, First Spear confirmed to me that although they provide some of their technology like Tubes to Natick, they had no involvement in fabricating these ABN-TAP prototypes. The second version (top center) is labeled as being made by SEKRI. Based on the pictures released by the Army, this is the version I believe that was provided for testing at Fort Bragg. The third (bottom right), all multicam version, is also unmarked. I suspect this is close to the “finished” version that will be more widely issued to Airborne units of the Army.

The ABN-TAP, as shown, has some good points. Obviously, the wider, unpadded M1956-like H-harness yoke will be more comfortable – and no doubt more stable under load – to wear for longer periods than the narrow ALICE-like Y-harness yoke that comes with the TAP. As a side note, I am not a believer in the premise that entirely unpadded yokes are ideal for long term wear. With a full combat load, a little padding goes a long way to providing some needed comfort for the shoulders. The ABN-TAP yoke has webbing bars on the back to allow for the direct mounting of a hydration carrier or MAP. A useful feature that is missing from the FLC and TAP. It is also true that the JOKER drop mechanism works as designed and that will streamline the parachute rigging process. Likewise, the use of a First Spear Tube facilitates quick donning and doffing. That is about it for the positives.

One of the most glaring oddities of this system is that it is clearly not designed to directly replace the TAP. Even calling it a TAP as if it is in the same category as its predecessor is a misnomer. The ABN-TAP is a chest harness and is not designed to work like the TAP. At best, since it has to be worn on top of armor, it is more of a replacement for the FLC. However, while both are “slick” without built-in magazine or other hard gear pockets, the ABN-TAP has considerably less PALs surface area than the FLC. Likewise, the ABN-TAP provides less than half the potential load carriage “real estate” compared to the current TAP which does have built-in internal storage space. That is a poor trade-off. Moreover, the ABN-TAP is absolutely not set up to readily “plug and play” with issue body armor or plate carriers as is the TAP. Indeed, the JOKER mechanism is semi-permanent and is not user friendly or expedient to assemble, adjust, or disassemble. In short, it is a PITA to manipulate and does not allow for the yoke to be dropped and reattached as expediently as the older TAP.

There are some other issues with the ABN-TAP that make me scratch my head. For one thing, it is not a good idea to put those female QASM buckles on the back panel. It probably does not matter if wearing body armor; but, when worn without armor under a heavy rucksack they will likely cause hot spots or even welts on soldiers’ backs. I am sure that was done to conserve the already limited space on the front panels. However, in terms of comfort, it would be better if those buckles were shifted to the front panels instead. There is also a lot – I would say an excessive amount – of webbing supplied to adjust the harness horizontally. When fully extended, the ABN-TAP is 64 inches across! Do we have Soldiers or Marines who are 64 inches in diameter? I looked up Dwayne “The Rock” Johnson’s stats. At 6 feet 5 inches, and 260 pounds, he has a 50-inch chest. I suppose that with body armor and a puffy Level 7 parka HE might need all 64 inches of room…maybe. Most of the rest of us could do without all of that extra webbing.

I was always taught that if you identify a problem you should also present some possible solutions. Hence, I have some suggestions. Upfront, I appreciate First Spear’s innovative technologies and Natick’s dedicated and quality work on this project. I have no doubt the ABN-TAP delivers exactly what they were asked to deliver. It just is not a fully effective replacement for either the FLC or the TAP. Do we really need three load carriers in the system when one could do? I recommend eliminating the problematic drop-down mechanism first. It is a permanently sewn-in superfluous solution to a temporary problem. Even for paratroopers, the rig is only going to be worn under a parachute harness for very brief periods of time. The exact same effect can be more simply achieved with two ~18-inch straps (as shown below) The straps can be used during rigging procedures to drop the front panels clear of the parachute harness. After the jump, they can be easily removed and stowed or used as cargo lashing straps on the harness or rucksack.

I have said before that there is no such thing as perfect gear and that everything needs at least some customization to better serve each individual trooper and specific mission needs. Likewise, there is no “universal” gear that can be all things to all people at all times. However, we can approach the broadest utility possible by maximizing the options for unit and individual customization. I suggest that can best be achieved by modifying the ABN-TAP yoke to make it a stand-alone item that can be instantly attached and detached as missions dictate. Additionally, simplify and standardize the design with a single identical panel template that can be used alone as a placard or minimalist chest rig or “daisy-chained” with one, two, or even three other panels into a TAP, a full (high ride) chest rig, or an old-style (low ride) H-harness; whichever is preferred. A truly modular and more flexible system like that should be able to effectively replace all the legacy FLCs and TAPs across the Airborne, the Army, and ultimately throughout DoD.

I have attached a picture or two of some pieces I cobbled together to show what I am talking about – a mock-up of the ABN-TAP A1 if you will. There is nothing expensive, radical, or even very innovative here. These are mostly commercial off the shelf (COTS) design features that have been available for decades. Many pre-date MOLLE and have been used by the military and commercial gear companies in other applications. First, the use of web loops on 3 sides of the panels – rather than sewn on straps –facilitates modularity, interchangeability, and field repair, with no left, right, or rear, specific panels. Tactical vests from various manufacturers had those loops in the 80s. Paired with a modern split bar, a.k.a. repair style “Fastex” buckle, these loops allow a soldier to use a variety of methods to link elements of the system securely together horizontally and vertically. That includes the option of lacing up with shock or 550 cord, male to female buckles including QASM versions, or the appropriate length of 1-inch webbing and split loops and/or buckles as displayed in this last picture.

I used three similar but not identical panels to illustrate the concept since I did not have three of a kind on hand. As I alluded to earlier, I believe one of the best features of the TAP is that it provides internal space for weapons magazines and some other items. I used two Beez Combat Systems (BCS) placards on the ends. The panel in the middle is no longer available but came from Hybrid Defense Strategies. It can be worn flat, but the built-in envelope allows for magazine inserts to be used (not shown). Unlike the current TAP designed only for the M4, I think it would be advisable to have slots on the ABN-TAP panels sized slightly larger to accommodate magazines beyond 5.56mm; including 7.62mm and 6.8mm, as well as some common individual radios, GPSs, and similar sized items.

Carrying these “common to all” items internally is not just a stylistic preference. If there is no internal space made available, ammo pouches or shingles have to be mounted on the outside and then other items like IFAKs, radio pouches, grenade pouches, and utility pouches for NODs, have to be stacked on top of the ammo pouches. Multi-layered pouches tend to be overly bulky, sag under combat weight, and interfere with access to each other. In the ABN-TAP’s case, since it does not convert readily into TAP mode as is, a soldier would need to have two full sets of pouches – or be prepared to move the pouches from body armor to harness and back for every jump or mission change. No one is going to want to do that routinely – nor should troopers have to. It would also be preferable for a soldier to set up his or her pouches just one time on the harness and train with that identical set up whether attached or detached from their armor carrier.

I used short straps from Velocity Systems to connect the panels for my example but have also displayed some others of varying lengths I had made for different projects. Laid out this way the 3 panel A1 harness is 54 inches across. Still too big for me but just right for The Rock. I should also point out that if my ideas were ever incorporated onto the ABN-TAP, the First Spear Tubes would be incompatible without some sort of adapter. I suppose for some, that might be a deal-breaker. I think it is a reasonable trade-off. Moreover, First Spear makes a split bar repair version of their Tubes and could perhaps make a version that works on three slots rather than two and solve that problem if the Army asked for it. Finally, although it did not receive much notice earlier, the ABN-TAP was tested with a new version of the Triple Magazine Pocket (shown above) that closes with reverse flaps like those on the TAP. That looks like a worthy product improvement to me and I presume those will be issued with the ABN-TAP.

De Oppresso Liber!

LTC Terry Baldwin, US Army (Ret) served on active duty from 1975-2011 in various Infantry and Special Forces assignments. SSD is blessed to have him as both reader and contributor.