FORT BELVOIR, VA – Project Director Soldier & Squad Integration (PD S&SI) hosted a side-by-side gear comparison between Project Executive Office (PEO) Soldier and U.S. Army Special Operations Command (USASOC) on Fort Belvoir, March 8-10.

PD S&SI held an event at the Soldier Integration Facility on Fort Belvoir, designed to provide a familiarization of selected items from Project Manager Soldier Survivability (PM SSV) and USASOC’s respective portfolios.

“We put the event together and facilitated bringing everyone in at the same time,” said Christopher Baker, survivability and power lead for the operational synchronization team for PD S&SI. “USASOC’s chain of command believed that they could realize some cost savings by leveraging the work that PEO Soldier is doing and what they’re fielding. The most interest and discussion were around the protective equipment, helmets and body armor, and the differences between what PEO Soldier fields and what USASOC has right now.”

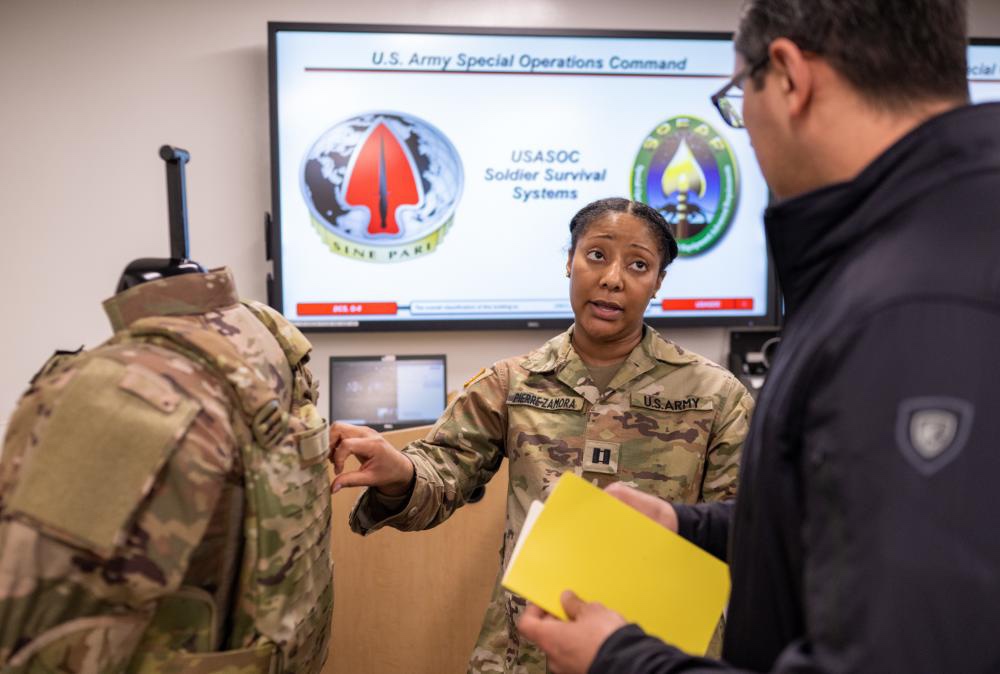

Product Manager Soldier Protective Equipment (PdM SPE) displayed the modular scalable vest (MSV), the blast pelvic protector (BPP) and the ballistic combat shirt (BCS). SPE personnel went over the capability and functions of the MSV, BPP, BCS, their threat levels and the differences between the Enhanced Small Arms Protective Inserts (ESAPI) plates and the legacy ESAPI plates. The SPE presentation highlighted the Army’s focus on increasing protection but slimming down on weight.

“A lot of the questions we received were predominantly on sizing and the kinds of threats our plates stopped,” said Capt. Kim Pierre-Zamora, assistant product manager for PdM SPE. “For us, the key message we want to convey to our audience, especially the Special Forces community, is that not only are we scaling back on these extra areas of redundant coverage or parasitic weight, but we’re also able to scale up the coverage depending on what they’re doing, where they are, and their commander’s intent.”

“Not only are we looking to make Soldiers lighter and more mobile, but also more lethal. Because if they can move enough to avoid a threat, they can engage that much better.”

The gear comparison not only presented an opportunity for USASOC personnel to get their first hands-on look with gear currently fielded by PEO Soldier, but it allowed for in-depth discussion of what goes into developing and producing that equipment.

“From my perspective, especially working in Future Capabilities, it’s good to see where the Army is with their equipment,” said Lt. Col. Rachel Cepis, S8 Future Capabilities Director, 95th Civil Affairs Brigade. “At the tactical level, you hear Soldiers sometimes complain and say, ‘why is this like this?’ or ‘when are we going to get this?’ Therefore, it is good to be able to see what is out there and being developed. It’s going to be helpful for me to be able to pass that message on to other Soldiers.”

The gear comparison event was the first step in developing the relationship between PEO Soldier and USASOC, with the future collaboration already in the works. Within the next six months, a future follow-on event, hosted by USASOC, will be scheduled.

Story by Jason Amadi, PEO Soldier

But SPEAR is so much better…

Mom can we have Crye AVS and thinner lighter cyradyne plates? Shut up we have AVS and thin plates at home (points to modular scalable vest and ESAPI).

“you can have whatever you like when you get a job and move out”

The AVS is a really good PC worth spending personal funds on.

It must be pointed out that you don’t invent by committee and that is what PEO does. Any number of manufactures can and do make armor better than the MSV at a fraction of the cost. The Extreme Cold Weather System is wildly out of date and needs a puffy jacket to replace the bulky, heavy and not all that warm fleece jacket. Just do an RFI to submit a replacement and it will be lighter, cheaper and better than what PEO “invents”. Same with load bearing equipment, mag pouches, IFAK, crappy issued assault pack etc.

Industry can and does make the item better and cheaper than PEO can and the fact that this waste of taxpayer dollars continues if beyond me.

PEO Soldier should just contract out what it wants (Armor carrier, pouches, ECWS, rucks, etc) and we can get iterative changes faster and with less red tape. Enough of this cold war era procurement.

But Seamus, what would all the PEO staff do if they actually became an agile organization?