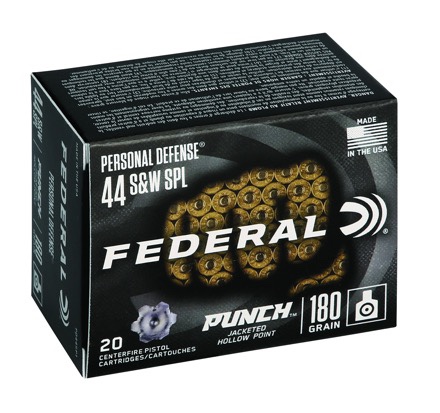

ANOKA, Minnesota – February 7, 2022 – Federal Ammunition is proud to announce an expansion of one of the most exciting lines of defensive loads to hit the market in years: Federal’s Punch ammo. Since its launch in 2020, Federal’s Punch has won several industry awards for its effectiveness and performance. New for 2022, a .44 S&W Special load has been added to the award-winning product line.

“We saw a need for a reliable, accurate, terminally effective option for the .44 S&W Special that doesn’t have to be the top scoring product in duty ammunition test procedures,” said Federal Handgun Ammunition Product Manager Chris Laack. “So, we looked at specifications from our Hydra-Shok Deep, HST and other bullet designs, and took what made sense for Punch. We modified the thickness of the jacket, skive depth, hollow point geometry and even differences in lead cores to build the recipe for Punch in .44 S&W Special.”

Federal Ammunition has been a leading producer of law enforcement ammunition for more than thirty years. Drawing on knowledge built over three decades, the company recently set out to develop a new self-defense load that would provide excellent overall performance in the .44 S&W Special chambering. This 180-grain jacketed hollow-point bullet provides a great option for common self-defense scenarios, such as an extra-heavy clothing test using ballistic gel. Punch is engineered to function equally well in both revolvers and carbines chambered for this classic cartridge.

“Shooters need a simple answer to the ‘What ammo do I need for self-defense’, question,” said Federal Handgun Ammunition Product Manager Chris Laack. “Things to consider such as function, reliable ignition, barrier performance, terminal performance, ballistics and other considerations are a lot to digest for most people. What some consumers really need to know is it will function in their gun, every time, and that it will be effective stopping a threat as quickly as possible. Punch’s .44 S&W Special is our easy answer for them.”

Most concealed carry permit holders are less concerned with factors such as barrier penetration through steel, plywood and auto glass. They are more concerned about choosing a bullet that is engineered from the ground-up to stop an attacker and work effectively in their chosen firearm. And, as the data shows, Punch bullets perform well in the tests that matter most to the average shooter. Federal has made Punch ammunition a natural choice for concealed carry.

Punch ammunition’s .44 S&W Special Load features Federal’s high-quality brass cases, advanced powders, and the sealed reliability of high-quality, sensitive primers. With Punch, self-defenders can be confident that their chosen load will out-perform comparably-priced competitor rounds. The new Punch option joins the .380 Auto, .38 Special +P, 9mm,.40 S&W and a .45 Auto loads released in 2020.

The new Punch option is a .44 S&W Spl. 180-grain offering with an MSRP of $35.99 per box of 20.

Federal ammunition can be found at dealers nationwide or purchased online direct from Federal. For more information on all products from Federal or to shop online, visit www.federalpremium.com.