The Safariland Group Unveils Groundbreaking Armor at SHOT Show Safariland continues to innovate with armor purpose-built for performance and comfort

Click to view .pdf

ONTARIO, Calif. – The Safariland Group (‘Safariland’) today debuted the all-new Safariland® Armor collection, a complete line of ballistic panels and carriers built for performance. Designed to integrate together, to perform, move, flex and respond as the body does, delivering unprecedented protection, comfort and fit, the line is being revealed at the 2016 SHOT Show in Las Vegas, from January 19-22. By reinventing existing armor solutions from the ground-up, Safariland Armor will change the way officers think of and wear armor

The Safariland Armor collection is comprised of five distinct panel designs that work universally with all the carrier models to meet any department’s need and budget. Each ballistic panel is developed with high-performance materials and technologies and feature cuts that maximize coverage and maneuverability. The new carrier lines, in both covert/concealable and overt/external designs, utilize advanced materials and performance fabrics to work with the body and maximize comfort in a large range of styles to cover duty, tactical and mission-specific needs.

“For us, success is every saved life,” said Todd Mackler, Vice President, Armor. “Forming a holistic system, we are taking armor to the next level of performance. Every detail has been considered: scalability, durability affordability and comfort to meet the demanding needs of both male and female officers.”

Each of the five panel packages are the best of wearability and stopping power – unparalleled performance based on actual field wear-testing.

SX – Flagship design that is one of the thinnest, lightest, and strongest ballistic products available on the market.

Summit™ – Utilizes advanced and exclusive materials that deliver exceptional ballistic performance while providing the ultimate in comfort and flexibility.

Xtreme® – A versatile and flexible package featuring 100% aramid based material that features advanced perimeter stitching for all-day comfort and performance.

Monarch® – A hybrid design that balances value, blunt trauma, and special threat ballistic performance.

Prism® – Combines advanced materials and design to protect against both stab and ballistic multi-threats.

The new Safariland Armor carriers introduce a system customizable for the individual officer, interchanging perfectly with every ballistic panel and carrier.

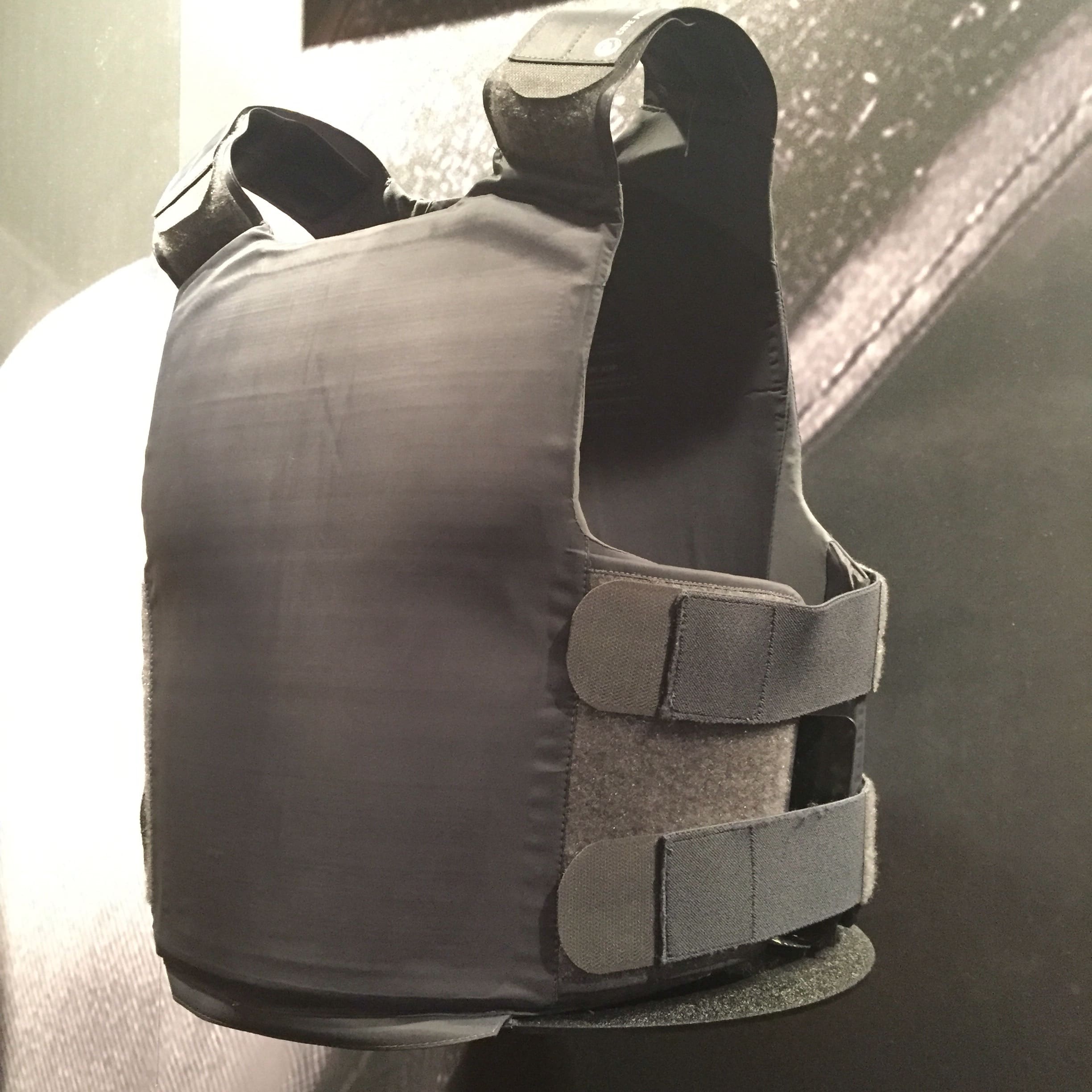

The ultra-concealable Covert, or concealable carriers, prioritize ergonomic designs, lightweight fabrics and contoured stitch lines. The carriers in the Covert line – Models P1, F1, M1 and E1 – feature high-performance laminated four-way stretch fabric and cooling spacer mesh liner. Further, an anti-microbial liner to inhibit odor causing bacteria is included on the F1, M1and E1.

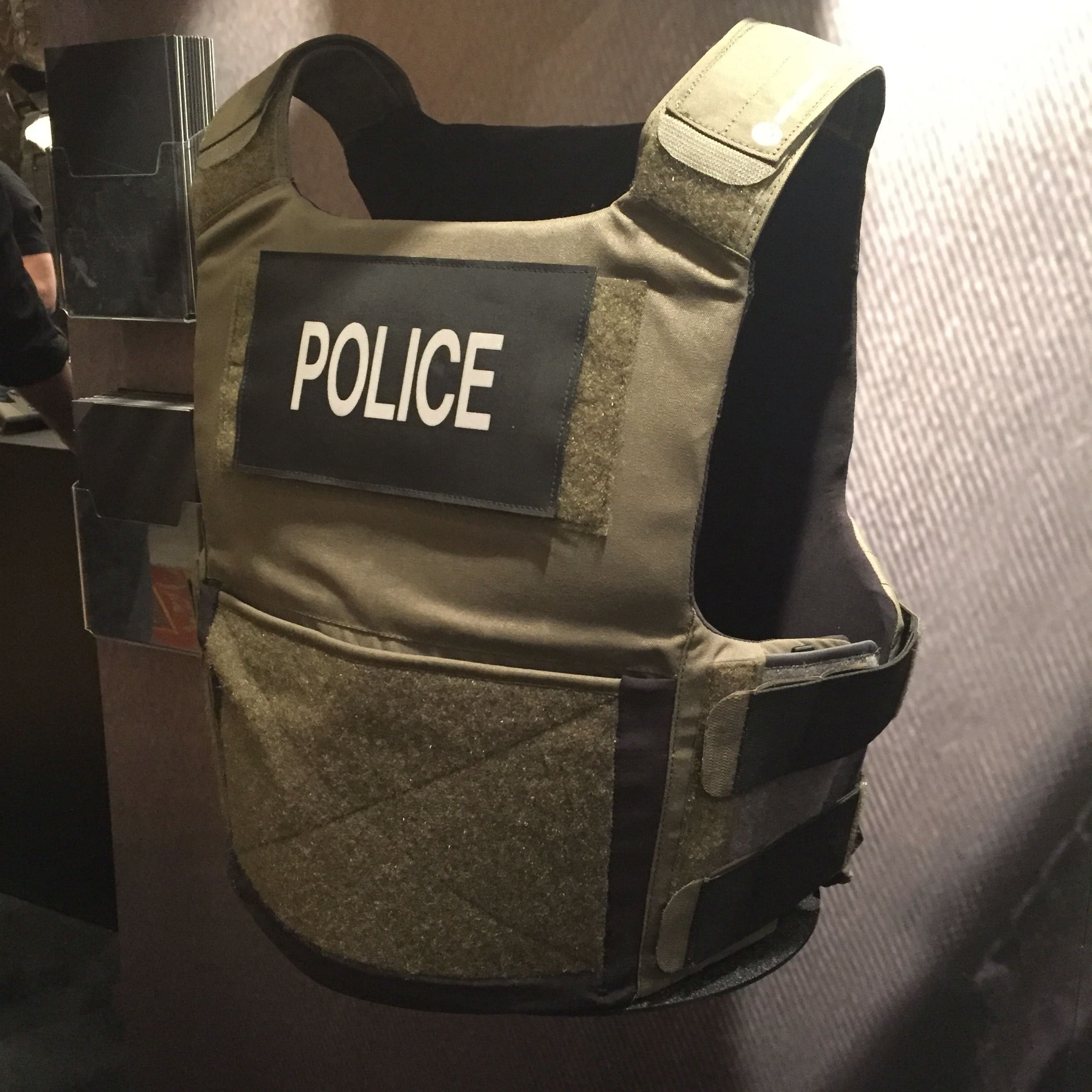

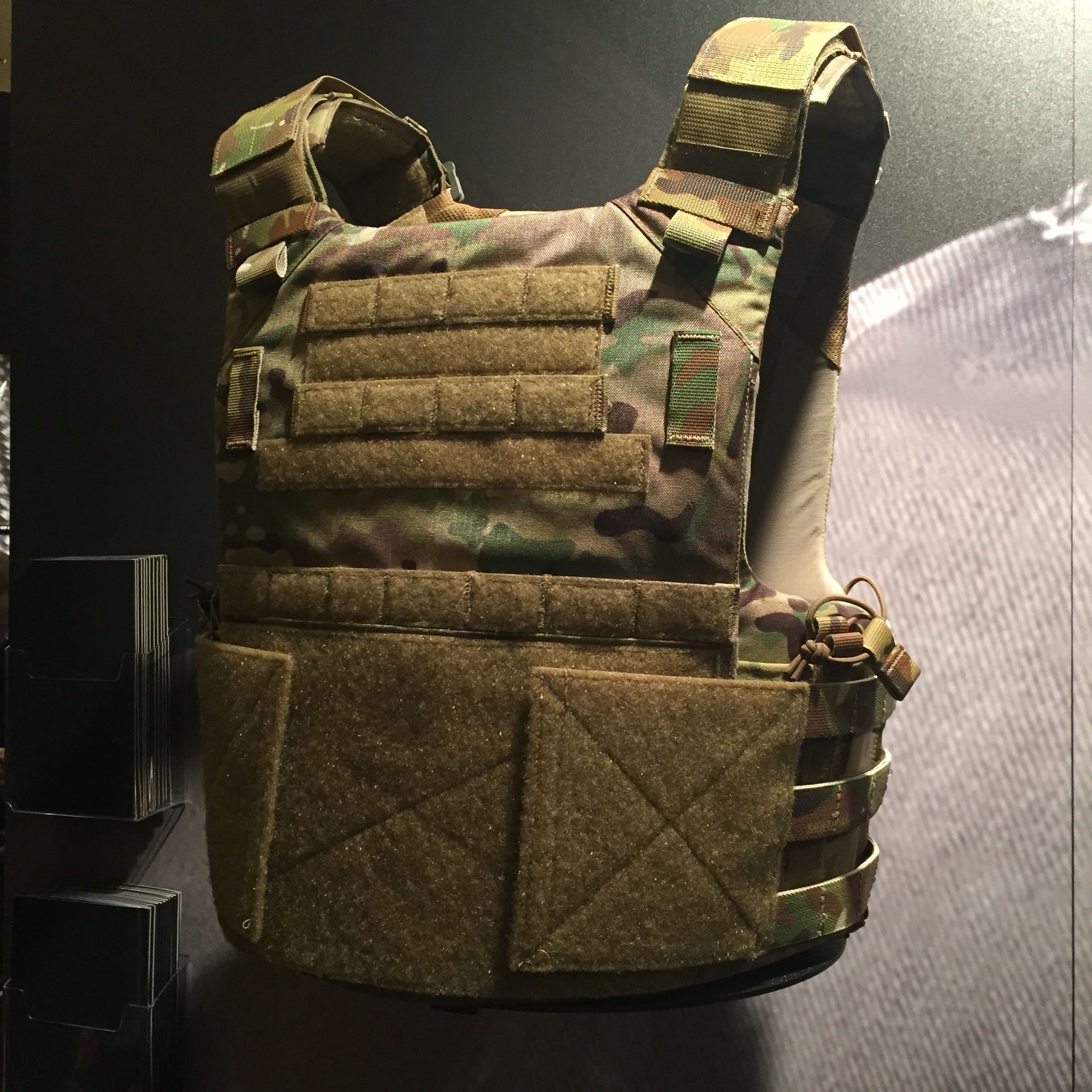

The Overt carrier options, worn externally, feature traditional and load bearing styles for versatility, fit and adjustability. Among their many features, the V1 and U1 overt carrier models encompass a hidden gun pocket, Velcro®-adjustable shoulders and ribbed channel-spacer cooling mesh. Each of these models is offered in either front- or side-opening options for officer preference. Further, the V1 models feature laser cut webbing for attaching equipment.

A unique product within Safariland Armor’s product line, the HyperX™ is a scalable solution that exemplifies the next generation of armor. This integrated system, consisting of a performance base layer T-shirt made of stretch fabric that moves and flexes, and a ballistic carrier, both have soft armor plate pockets for enhanced coverage and protection. The sleek, athletic styling and performance materials offer exceptional comfort and flexibility for all day wear.

Through Safariland’s years of experience and collaboration with leading manufacturers in ballistic technology, this armor is engineered for better compositions and designs integrating ballistic performance and human performance. Best-in-class industry partners include TexTech Industries, Teijin Limited, DuPont Kevlar, Honeywell International Inc., SAATI and Barrday Protective Solutions.

www.safariland.com/bodyarmor