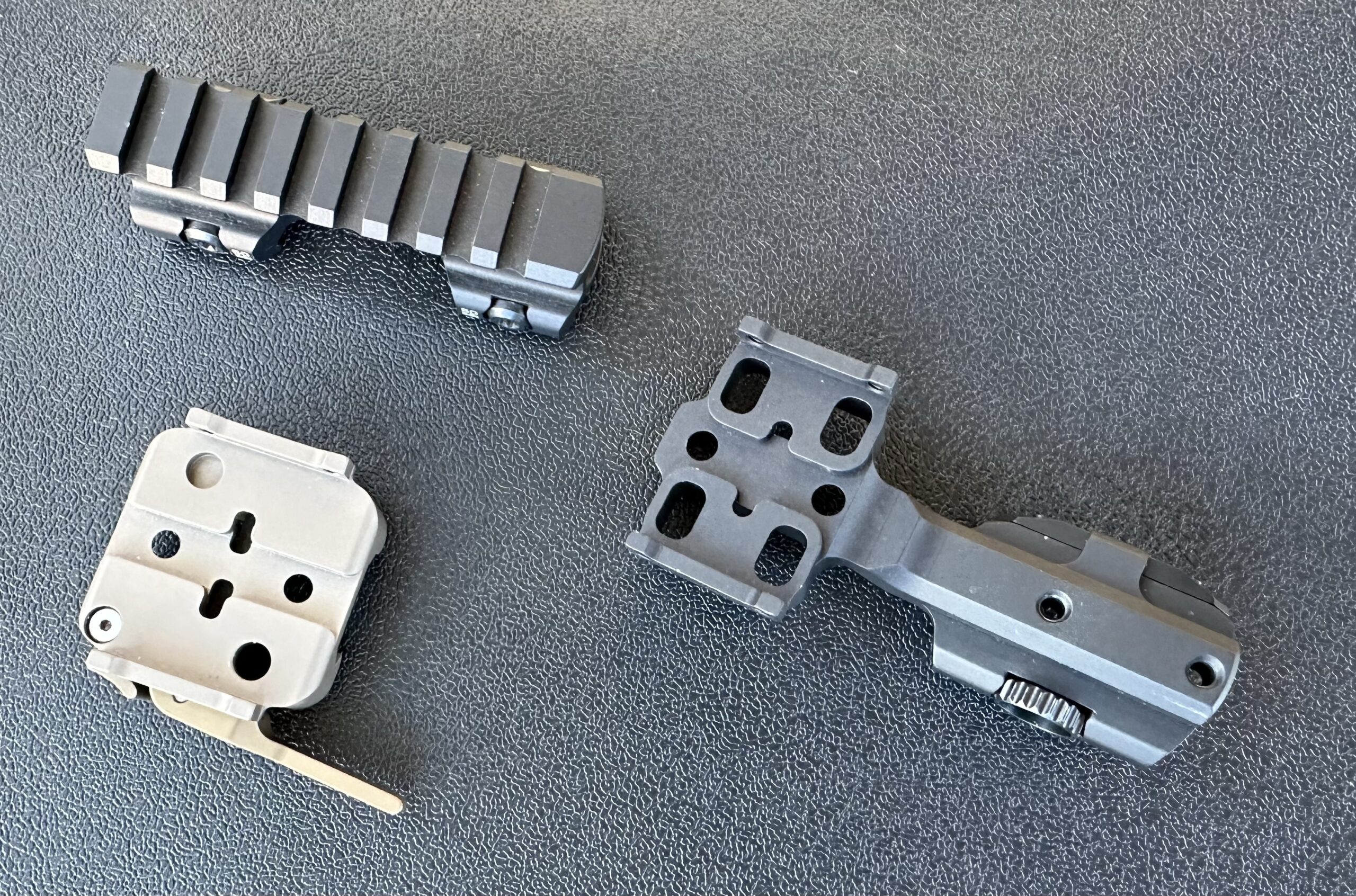

XTech Tactical has expanded its magazine / grip extension product line for the Sig Sauer P365. The newest version is the MTX 365-380, a 10rd to 13rd magazine and grip extension for the Sig Sauer P 365 380 pistol. The kits offer the ideal ergonomic grip and 3 rounds to the magazine.

The MTX 365-380 shares the same external housing with the other XTech Tactical MTX 365 offerings, but has a custom engineering 17-7 extended spring, easy loading follower, and spring button spacer specific to the MTX 365-380. Like the factory P365 10rd magazines, the .380 kit once installed will not allow the loading of 9mm. The kits fit both 9mm and 380 magazines for use with the P365 380.

The kits are now shipping and available at the below link as a single and two pack:

www.xtechtactical.com/product/mtx-365-380-3-round-magazine-extender-with-spring-for-p365

MSRP for the MTX 365-380 is $24.95 with a two-pack option available for $42.95.

All components are 100% Manufactured and Designed in the US.

About the MTX 365:

With the MTX 365 installed, the user can easily maintain a complete grip on firearm, a full purchase of the palm area and a proper high grip on the pistol frame. The aesthetics of the extender match the P365 frame with a functional texture on the side panels for rapid extraction if needed.

The product uses both of the company’s now issued US utility patents for magazine extensions, US11408697B2 and US11168954B1.

The MTX© line up now includes options for:

Sig Sauer P365 9mm 10rd Magazines +3 & +0 for restricted states

Sig Sauer P365 380 10rd Magazines +3

Smith & Wesson M&P Shield 1.0 & 2.0 +2/+1 in both 9mm and .40 S&W

Smith & Wesson M&P9 Full Size +5 for the 1.0 & 2.0 in 9mm

Heckler & Koch VP9/P30 +4/+6 Full Size in both 9mm & .40 S&W

Heckler & Koch VP9sk/P30sk +2/+1 in both 9mm and .40 S&W

Coming Soon:

Sig Sauer P365 380 10rd Magazines

Sig Sauer P365 9mm 12rd Magazines

Website: www.xtechtactical.com