Bravo Company has just launched A/T (Angled Torque) Optics Mounts for the Aimpoint T1, T2, Comp M5, and Trijicon MRO.

BCM A/T OPTIC MOUNTS

Capability in the face of the unexpected and catastrophic – the BCM A/T mount is built in anticipation of a “no fail” shot that will save another human life.

PERFORMANCE WITHOUT PEER

Improving on Mil-Spec rail interfaces dating back over 30 years, the BCM A/T mount delivers an unprecedented zero retention on a properly mounted red dot optic. Low profile and snag- free, BCM A/T Mounts are built with a minimal number of components – delivering a stronger component with less points of failure, ready to take on dynamic and adverse settings.

Each A/T Mount features multiple integral recoil lugs to mitigate recoil and counter recoil to preserve your zero and ensure “no fail” shots are placed where intended by the trained rifleman.

Starting at 2.15 oz, each 7075T6 billet mount is hard coat anodized per Mil-A-8625F. Additionally, both the steel alloy clamp and nut are hardened with Nitride coating.

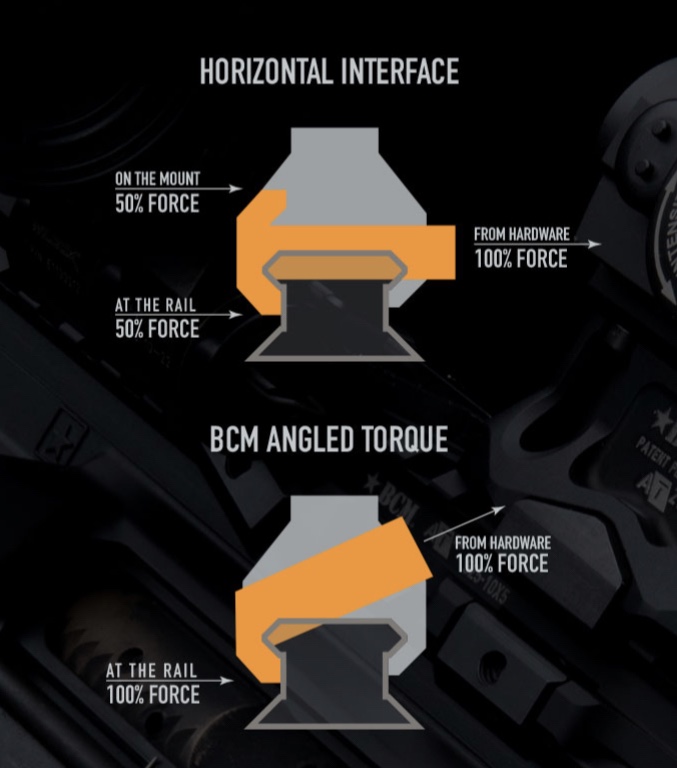

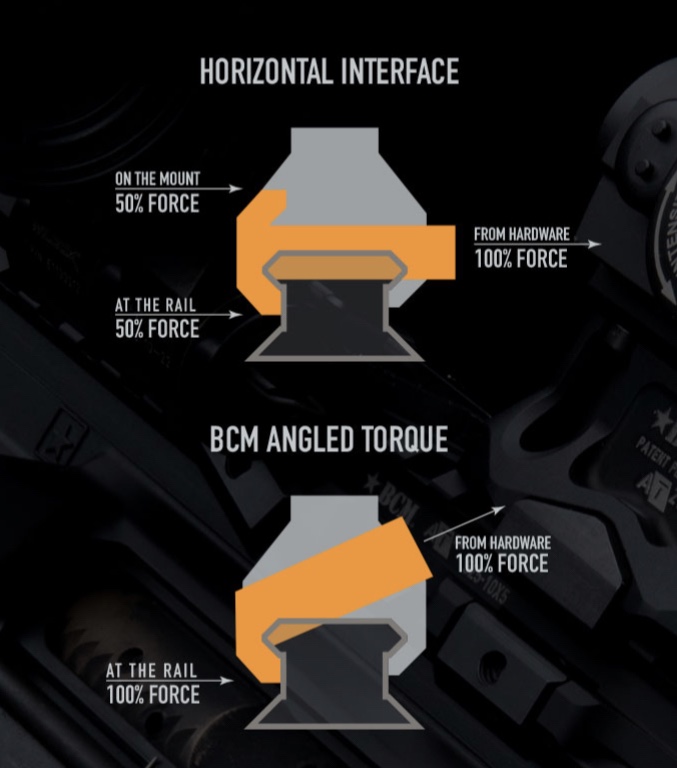

THE ANGLED TORQUE LOCK-UP

A/T mounts employ angled torque through a patented* clamp which applies triangulating force to create a stronger and more reliable lock up of the mount onto the end user’s rail.

To retain the hardware in field conditions, this system uses a serrated locking spring-washer to prevent the loss of torque on the shaft nut.

With an equivalent load applied, the A/T Mount delivers approximately twice the clamping force at the picatinny rail, versus a legacy horizontal interface.

THE FLEET

Built optimized for both a variety of missions and proven red dot optics.

Aimpoint® T-2, T-1 and CompM5 series

+ The Marksman lower 1/3 co-witness

+ The Close Combat 1.93”

Trijicon® MRO®

+ The Marksman lower 1/3 co-witness

+ The Close Combat 1.93”

Get yours at bravocompanymfg.com/at_mount.

* US Patent D973.826, and other patents pending

* Aimpoint, T-2, T-1, CompM5 trademarks are property of Aimpoint Inc.

* Trijicon, MRO trademarks are property of Trijicon Inc.