Last week, I had the chance for a quick visit to XGO’s parent company, Longworth Industries, to tour not only their factory, where they assemble garments, but also their mill, where they create their fabrics.

The factory was humming right along when I arrived mid-afternoon. Longworth currently runs one shift per day in this factory which produces XGO clothing for military and LE customers all year long, with seasonal production of their commercial, Polarmax line.

At any one time, Longworth Industries holds about $1.5 Million in raw goods, but not much of it lays dormant. Each lot is checked for proper color shade and to ensure the fabric meets its basic characteristics.

While each day, the management team lays out the day’s production goals, fabric is cut in a continuing process to stay ahead of the sewing floor.

One of the most interesting processes for me was their use of ink cups to print labels. Longworth had previously used a heat transfer process for their labels.

Conveniently, Longworth’s fabric mill is located right next door to their garment factory.

The majority of XGO’s Berry Compliant fabrics are milled here. Above, you see a bi-component knit being woven with different outer and inner yarns. They also use a dye house located nearby and the XGO headquarters and warehouse aren’t far away. The close proximity of their supply chain helps control costs.

The mill runs three shifts with some additional overtime. That’s an interesting ratio. At their current rate, which includes a multitude of variables, they run three shifts at the mill to produce one shift’s worth of garments.

Although central North Corlina was once well known for its textile industry, new employees must be trained, particularly sewing machine operators. This is an issue, I’ve seen time and time again, regardless of the location. People just don’t grow up sewing anymore. However, the team they’ve got right now, was doing a great job of assembling garments.

I want to thank to Longworth Industries team for hosting me on short notice. They have assembled a great team.

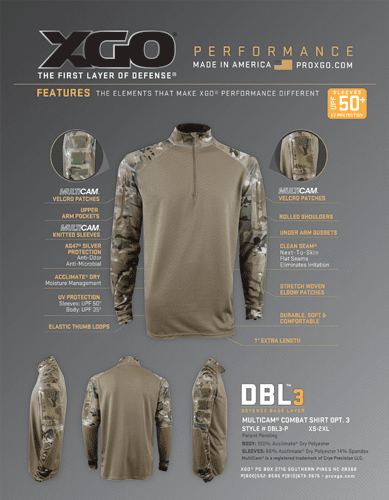

www.proxgo.com