stores.octactical.com/the-resistance

This is the thirty-eighth installment of ‘Max Talk Monday’ which shares select episodes from a series of instructional videos. Max Velocity Tactical (MVT) has established a reputation on the leading edge of tactical live fire and force on force training. MVT is dedicated to developing and training tactical excellence at the individual and team level.

This video examines, with the help of army men on a sand table model, the concept of the ‘assault through’ as part of the dismounted light infantry attack. Including a thorough background and context on how and when to run the drill, it also gives variations on the standard U.S. Army doctrinal drill.

This is the fourth installment of ‘Max Talk Monday’ which shares select episodes from a series of instructional videos. Max Velocity Tactical (MVT) has established a reputation on the leading edge of tactical live fire and force on force training. MVT is dedicated to developing and training tactical excellence at the individual and team level.

Max is a tactical trainer and author, a lifelong professional soldier with extensive military experience. He served with British Special Operations Forces, both enlisted and as a commissioned officer; a graduate of the Royal Military Academy Sandhurst. Max served on numerous operational deployments, and also served as a recruit instructor. Max spent five years serving as a paramilitary contractor in both Iraq and Afghanistan; the latter two years working for the British Government in Helmand Province, Afghanistan.

Website: Max Velocity Tactical

YouTube: Max Velocity Tactical

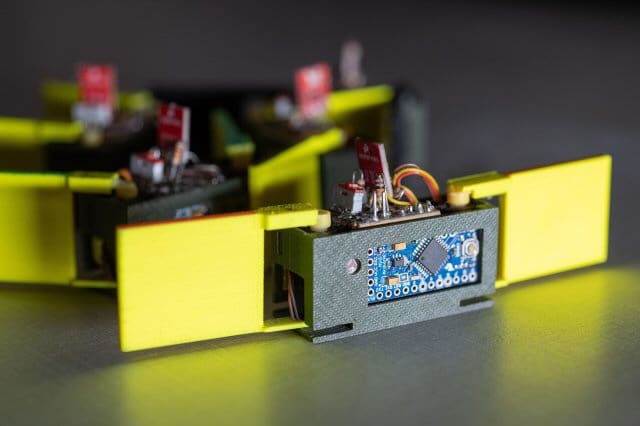

RESEARCH TRIANGLE PARK, N.C. — A U.S. Army project took a new approach to developing robots — researchers built robots entirely from smaller robots known as “smarticles,” unlocking the principles of a potentially new locomotion technique.

Researchers at Georgia Institute of Technology and Northwestern University published their findings in the journal Science Robotics (see related links below).

The research could lead to robotic systems capable of changing their shapes, modalities and functions, said Sam Stanton, program manager, complex dynamics and systems at the Army Research Office, an element of U.S. Army Combat Capabilities Development Command’s Army Research Laboratory, the Army’s corporate research laboratory.

“For example, as envisioned by the Army Functional Concept for Maneuver, a robotic swarm may someday be capable of moving to a river and then autonomously forming a structure to span the gap,” he said.

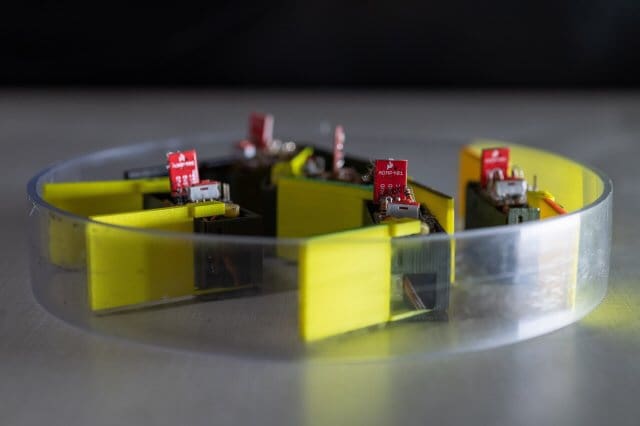

The 3D-printed smarticles — short for smart active particles — can do just one thing: flap their two arms. But when five of these smarticles are confined in a circle, they begin to nudge one another, forming a robophysical system known as a “supersmarticle” that can move by itself. Adding a light or sound sensor allows the supersmarticle to move in response to the stimulus — and even be controlled well enough to navigate a maze.

The notion of making robots from smaller robots — and taking advantage of the group capabilities that arise by combining individuals — could provide mechanically based control over very small robots. Ultimately, the emergent behavior of the group could provide a new locomotion and control approach for small robots that could potentially change shapes.

“These are very rudimentary robots whose behavior is dominated by mechanics and the laws of physics,” said Dan Goldman, a Dunn Family Professor in the School of Physics at the Georgia Institute of Technology and the project’s principal investigator. “We are not looking to put sophisticated control, sensing and computation on them all. As robots become smaller and smaller, we’ll have to use mechanics and physics principles to control them because they won’t have the level of computation and sensing we would need for conventional control.”

The foundation for the research came from an unlikely source: a study of construction staples. By pouring these heavy-duty staples into a container with removable sides, former doctoral student Nick Gravish — now a faculty member at the University of California San Diego — created structures that would stand by themselves after the container’s walls were removed.

Shaking the staple towers eventually caused them to collapse, but the observations led to a realization that simple entangling of mechanical objects could create structures with capabilities well beyond those of the individual components.

“Dan Goldman’s research is identifying physical principles that may prove essential for engineering emergent behavior in future robot collectives as well as new understanding of fundamental tradeoffs in system performance, responsiveness, uncertainty, resiliency and adaptivity,” Stanton said.

The researchers used a 3D printer to create battery-powered smarticles, which have motors, simple sensors and limited computing power. The devices can change their location only when they interact with other devices while enclosed by a ring.

“Even though no individual robot could move on its own, the cloud composed of multiple robots could move as it pushed itself apart and shrink as it pulled itself together,” Goldman said. “If you put a ring around the cloud of little robots, they start kicking each other around and the larger ring — what we call a supersmarticle — moves around randomly.”

The researchers noticed that if one small robot stopped moving, perhaps because its battery died, the group of smarticles would begin moving in the direction of that stalled robot. The researchers learned to control the movement by adding photo sensors to the robots that halt the arm flapping when a strong beam of light hits one of them.

“If you angle the flashlight just right, you can highlight the robot you want to be inactive, and that causes the ring to lurch toward or away from it, even though no robots are programmed to move toward the light,” Goldman said. “That allowed steering of the ensemble in a very rudimentary, stochastic way.”

In future work, Goldman envisions more complex interactions that use the simple sensing and movement capabilities of the smarticles. “People have been interested in making a certain kind of swarm robots that are composed of other robots,” he said. “These structures could be reconfigured on demand to meet specific needs by tweaking their geometry.”

Swarming formations of robotic systems could be used to enhance situational awareness and mission-command capabilities for small Army units in difficult-to-maneuver environments like cities, forests, caves or other rugged terrain.

The research project also received funding from National Science Foundation.

robotics.sciencemag.org/content/4/34/eaax4316

Story by U.S. Army CCDC Army Research Laboratory Public Affairs

Photos by Rob Felt of Georgia Tech

I can’t think of a better way to kick off your Monday morning.

A day in the life of U.S. Army Rangers assigned to 2nd Battalion, 75th Ranger Regiment, as they hone the skills needed to succeed in the world of Special Operations. Joint Base Lewis-McChord, Washington, August 2019. (U.S. Army video by Sgt. Jaerett Engeseth)

Rangers Lead the Way!

Raptor Tactical has introduced a World War Two-style net Helmet cover for the Army Combat Helmet.

Shown over a MultiCam cloth cover. Mesh is OD.

www.raptortactical.com/home/232-army-combat-helmet-net-cover-wwii-style

AUSTIN, Texas — When Sgt. 1st Class Will Roth joined the Soldier Lethality Cross-Functional Team on the first day of October last year, he was the youngest member of the team. At 34 years old, he was the only non-commissioned officer and the only National Guard Soldier on a team comprised of Colonels and senior level civilians.

“It was overwhelming and humbling at first. They told me I’d be doing things E7s don’t typically do. I learned really fast that no one here is driven by ego, and nobody cares about your resume, either. They want to know what you’re doing for Soldiers today,” Roth said, as he looked back on a whirlwind year that earned him enough frequent flier miles to take his wife and two sons on a nice vacation far, far away.

If only there was time for that. Come October 1, Roth leaves Fort Benning, Ga., for Arlington, Va., where he will work with the National Guard Bureau’s Training and Human Performance.

But he leaves the CFT with a great sense of satisfaction, having seen the concept of the Enhanced Night Vision Goggle – Binocular become reality. The hard work he invested with the CFT comes to fruition later this month when the goggles are fielded to the 2nd Armored Brigade Combat Team, 1st Infantry Division at Fort Riley, Kansas. They will take them to Korea early next year, where they will benefit from the ENVG-B capability to “see” in low- and no-light environments and weather conditions that would typically render a night vision device useless.

The ENVG-B has been Roth’s baby from the start; from the day he was tasked to serve as the technical advisor for the ENVG-B, one of the Soldier Lethality CFT’s portfolio of programs, which also includes Next Generation Squad Weapons and the Integrated Visual Augmentation System, or IVAS. Roth has participated in every single aspect of the development and testing of the ENVG-B, including eight Soldier Touch Points, which are significant milestones in the CFT’s aggressive process of development and acquisitions. Soldier Touch Points, or STPs, are training and testing events that put the binoculars in the hands of soldiers and Marines – hundreds of them – over and over and over.

They use the binoculars in a field training environment under a variety of conditions and offer feedback on the utility and practicality of the product. Practicality is important; user acceptance is critical.

“Honestly, first time I saw (the ENVG-B,) I was skeptical,” said Roth, who served in combat with the 2nd Battalion, 75th Ranger Regiment, early in his career and understands the needs of the combatant to move swiftly and maintain constant situational awareness. “It has to deliver both, and I couldn’t see that a year ago, early in the process. I couldn’t envision a time when Soldiers would accept this product and trust it in the field.”

That all changed when Roth participated in his first STP at Fort Drum, New York, where he watched a Marine lay on his back, fire over his shoulder, and hit targets at 50 and 100 meters using the Family of Weapons Sights — Individual, which gives the ENVG-B Rapid Target Acquisition capabilities, essentially the ability to see a target with the goggle wirelessly paired to the optic on the weapon.

“He hit five out of seven. It gave me chill bumps,” Roth said. “I decided this was an insane game changer. I’m a believer, one hundred percent. Nothing else offers these kinds of capabilities; I’ve seen it for myself, and I’ve heard it from hundreds of Soldiers and Marines.”

For his part, Roth said he is proud to have been a part of the “team of teams” that saw this capability from concept to fielding. And it was literally a team of teams. Though Army Futures Command is new, and it represents a new way of doing business when it comes to developing requirements and producing capabilities – faster and more efficiently – it absorbed a number of existing Army equities, such as the Combat Capabilities Development Command and the various Capability Development Integration Directorates.

The list is long, the network is complicated. With the ENVG-B, AFC’s SL CFT inherited the requirements process early on from the Maneuver Capability Development Integration Directorate and Program Executive Office Soldier worked with L3 Harris out of Londonderry, New Hampshire, to produce the product from prototype to fielding.

“AFC is designed to develop new relationships with academia and industry and capitalize on the institutional knowledge and the experience of existing organizations that we now call partners,” said Col. Travis Thompson, the Deputy Director of the SL CFT under Brig. Gen. Dave Hodne. “We all move in the same direction at the same time, and we move quickly; it’s very effective. But the key to the success of the whole initiative is the constant engagement with Soldiers, the touch points that allow us to develop rapidly. That’s Soldier Centric Design, the practice of putting the needs of the Close Combat Force at the center of everything we do, and to do that, we have to have them touch it, wear it, try it, evaluate it, over and over and over.”

The iterative process that incorporates STPs, some of them lasting for weeks, also includes other events designed for the same purpose but different missions: User Studies, Juries, Capabilities Sets, and Sprints. They all serve to hasten the identification of failures or shortcomings so as not to field a product that is more trouble than its worth from the Soldier’s perspective. It’s a fail early, fail cheap philosophy that drives the CFT’s pursuit of efficient and cost effective acquisitions in the quest for combat over-match.

“It doesn’t do a bit of good to develop a dynamic tool or a weapon that soldiers find inconvenient or one that slows them down or hinders their progress,” Thompson said. “By putting the ENVG-B to the test in field training exercises under a variety of conditions, we learned what worked and what didn’t, and we made the changes necessary at every step of the design and development process to ensure the product we field next week is not a novelty, but a practical tool that will make our Soldiers more lethal, more survivable and better able to maneuver in challenging conditions.”

Thompson speaks of a familiar concept once commonly called “Soldier as a System.” These days, proponents call it Adaptive Squad Architecture (ASA), and depending who you ask, it either drives or it’s driven by the Soldier Centric Design. ASA demands that AFC partners consider not only the need or problem that drives the development of any piece of the Soldier kit — the sum of everything the Soldier wears, carries or uses — but the impact it will have on other elements of the kit, the Soldier, and his or her squad.

“We’ve all heard the story of the body armor that rises up when you shoot from a prone position and forces your helmet to fall forward over your eyes,” Thompson said. “That’s what happens when you field a great piece of kit that doesn’t play well with others. That’s simplifies the concept of Adaptive Squad Architecture to an elementary level – very, very basic — but it sums it up nicely. Everything will work together so the whole is greater than the sum of its parts.”

Toward that end, Thompson said, the Soldier Lethality CFT will continue to develop programs, rapidly and efficiently, that work together to enhance the proficiency of the Close Combat Force, the roughly 100,000 Soldiers — or four percent of the Department of Defense – who close with and engage the enemy. The vast majority of them are Infantrymen, and historically, they incur 90 percent of casualties on the battlefield.

“The Army’s modernization strategy has one focus: to make soldiers and units more lethal to win wars and come home safely. Everything we do is centered on that goal,” Thompson said. “And we’re doing that successfully by leveraging emerging technologies, science, human potential and all of these partnerships that keep us moving aggressively toward over-match.”

The Soldier Lethality CFT continues to test prototypes of the IVAS, with plans to field in 2021, and the Next Generation Squad Weapon rifle and automatic rifle, which will replace the Squad Automatic Weapon and the M1/M4 Carbine, with plans to start fielding in 2023.

“We move quickly, but with a laser-like focus,” Roth said. “It’s all about the Close Combat Force, the guys who go in first and hit the ground running. That’s why the folks here hit the ground running every day.”

By Bridgett Siter, Communications Director, Soldier Lethality CFT