ABERDEEN PROVING GROUND, Md. – Material scientists from the U.S. Army and Department of Energy conducted a study of plasma-treated aluminum nanoparticles with the goal of improving future propellants and explosives.

Researchers from the U.S. Army Combat Capabilities Development Command, known as DEVCOM, Army Research Laboratory, and the Center for Nanoscale Materials at the Argonne National Laboratory, investigated a new class of surface-engineered aluminum nanoparticles. They published their findings in the peer-reviewed Journal of Applied Physics for a special issue, Fundamentals and Applications of Atmospheric Pressure Plasmas. The journal featured the article on the cover of its Feb. 14, 2021, issue.

“The ultimate goal of the effort is to extend the range and disruptive power of Army weapon systems,” said Dr. Chi-Chin Wu, a materials scientist at the laboratory. Wu leads this effort and is the first author of the article. “The paper presents results that support of ongoing investigations of aluminum nanoparticles for use as novel energetic ingredients in propellant and explosive formulation.”

The study exploits plasma-based surface treatment and chemical synthesis techniques, she said.

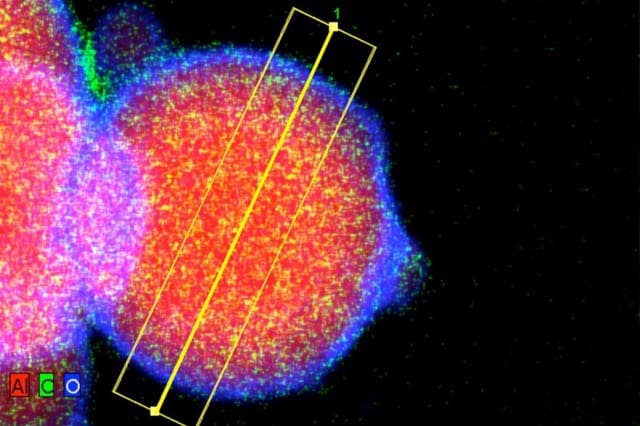

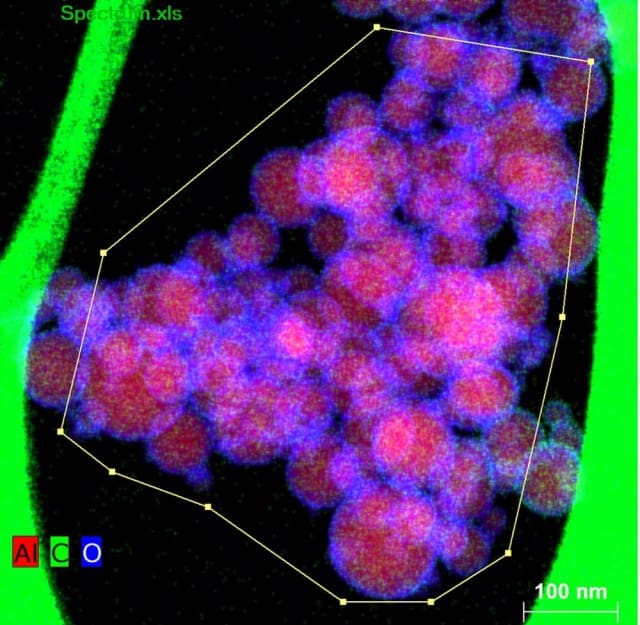

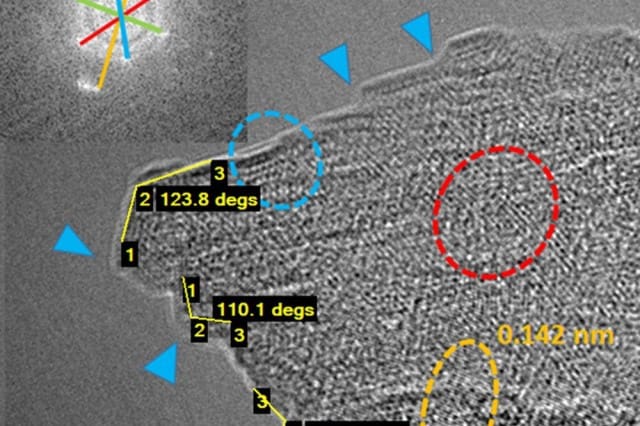

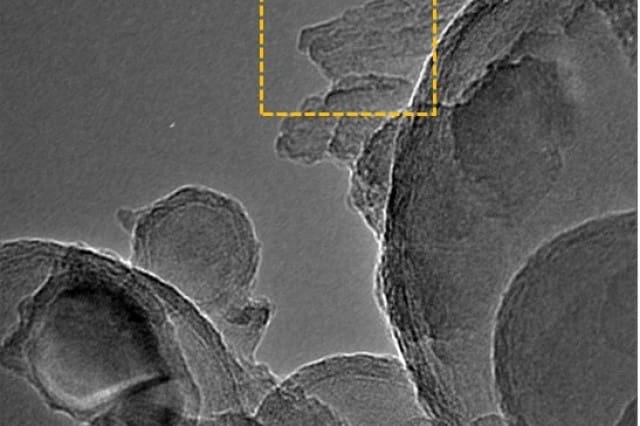

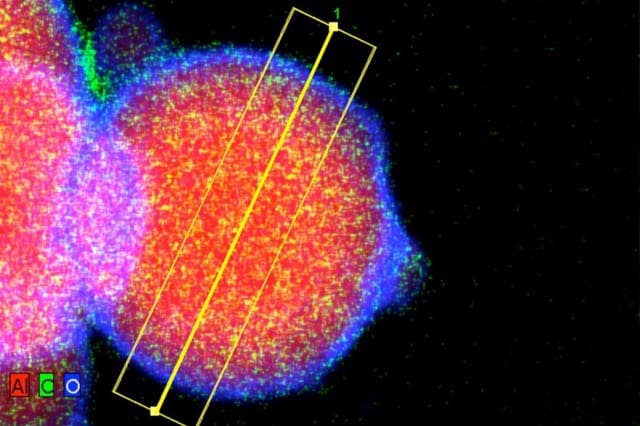

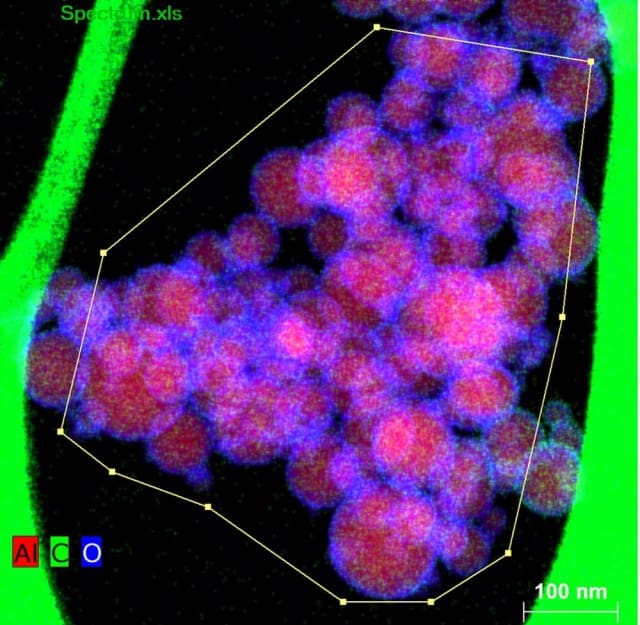

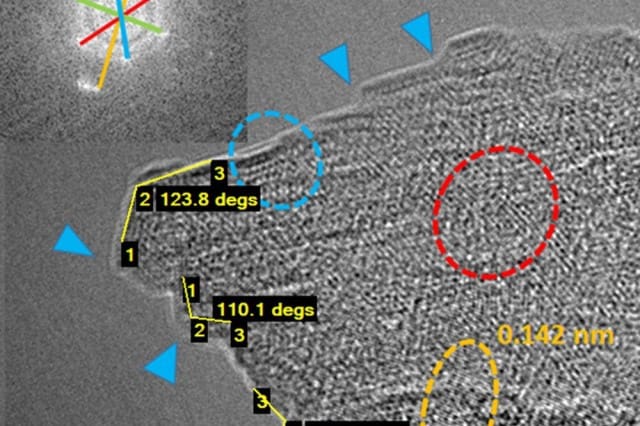

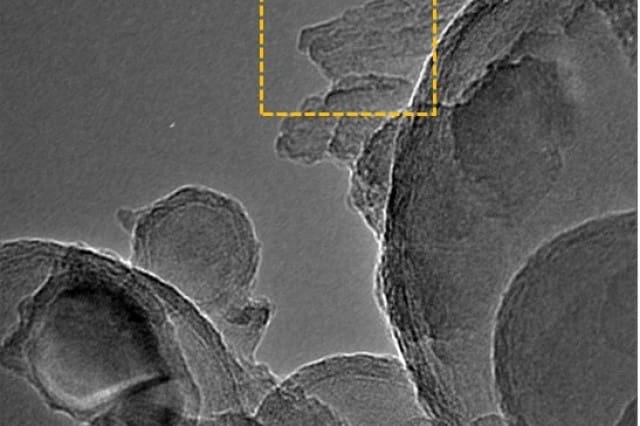

“Images and data obtained from two state-of-the-art transmission electron microscopes at the Center for Nanoscale Materials at the Argonne National Laboratory revealed valuable information on oxide shell phase transformation and the dispersive nature of the deposited carbonaceous materials,” Wu said. “This provides tremendous insight for further optimization.”

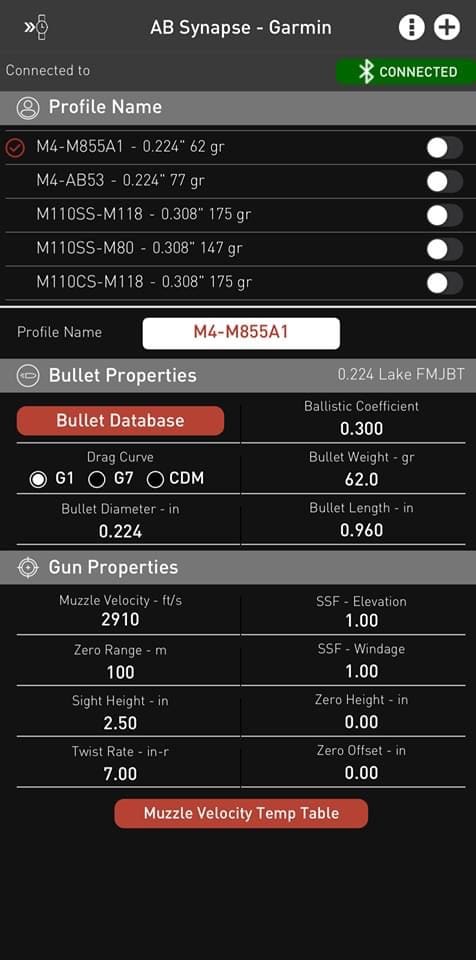

The new plasma approach enhances the reactivity of commercial 40-60 nanometer particles. For comparison, a human hair is typically 60,000 nanometers in width. According to Wu, the method involves first treating with a helium plasma to etch away a significant portion of their inert oxide shell and then treating with a helium/carbon monoxide plasma to deposit a reactive surface coating.

“Plasma science is a fascinating emerging technology for many applications but has yet to be sufficiently explored in the energetics community,” she said. “All this is done in a custom dielectric barrier discharge plasma reactor. The resultant particles were then characterized by high resolution transmission electron microscopy revealing important nanoscale surface and chemical composition features. We are constantly seeking new energetic materials with higher energy densities and faster energy release rates.”

Plasma treatment and synthesis, coupled with comprehensive material characterization, is critically important for optimizing methodologies and materials for scale-up and transition, she said.

Dr. Rose Pesce-Rodriguez, also from the laboratory and a co-author of the study, said the plasma approach developed by Wu has opened new possibilities for the U.S. Army to effectively surface-engineer metallic nanoparticles for energetics applications.

“Aluminum is just the first example,” Pesce-Rodriguez said. “Since 2018, several parallel efforts involving in-house, DOD, DOE and academic collaborations have blossomed. Making headway on this problem is difficult because samples are so small and require specialized technology to image and analyze.”

According to Pesce-Rodriguez, the microscopy tools available at DEVCOM-ARL and Argonne enabled Wu and collaborators to do a “remarkable job” of characterizing the new plasma-treated particles.

“We’re looking forward to more exciting discoveries,” Pesce-Rodriguez said. “It seems we’re learning something new almost every day.”

Wu said her ultimate goal is for DEVCOM-ARL to develop and transition energetic materials through a unique combination of innovative plasma technologies and advanced materials characterization techniques.

Collaborative partners in this study are Drs. Jianguo Wen and Ilke Arslan at the Center for Nanoscale Materials, Argonne National Laboratory.

“It’s been great to collaborate with Dr. Chi-Chin Wu and her team on advanced disruptive energetics,” Wen said. “This gives Argonne the opportunity to bring our expertise and unique capabilities to challenging Army problems.”

Dr. Mark Tschopp, the regional lead of ARL Central in the Chicago area, said this is a great example of collaboration between the Army and the Department of Energy.

“It combines the expertise of scientists at both laboratories along with unique facilities at the Department of Energy User Facility Center for Nanoscale Materials,” he said. “Expanding the Army team to include other partners is vital to tackling some of the fascinating and challenging science that the Army Research Laboratory is pursuing in areas such as at the intersection of energetics and plasma science.”

According to Wu, the work is an example of how the laboratory is working to operationalize science to provide energetics for transformational advances.

“It brings material science expertise into energetics for advancing future weapon systems,” she said.

The U.S. Department of Energy, Office of Science, Office of Basic Energy Science supported use of the Center for Nanoscale Materials, an Office of Science user facility, under an existing contract.

By U.S. Army DEVCOM Army Research Laboratory