Brownells Makes History, Launches Retro Rifles™ Line

Models include four 5.56mm and two .308/7.62 variants

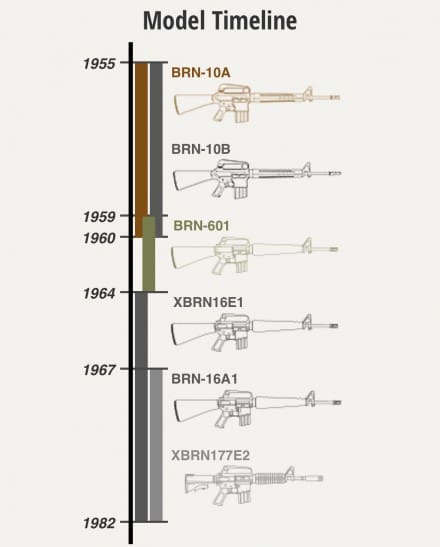

LAS VEGAS, Nevada (January 23, 2018) – It’s been 79 years in the making and today, Brownells has joined the ranks of America’s gun manufacturers. It also makes sense the company’s first firearms are legitimately old school – retro AR-15 rifles.

Brownells newly-created Retro Rifles™ line features four 5.56mm variants and two .308/7.62 variants. The 5.56mm models feature the correct styling for rifles issued to GIs in the 1960s. The .308/7.62 models reflect the lightweight styling of Eugene Stoner’s original AR-10® design.

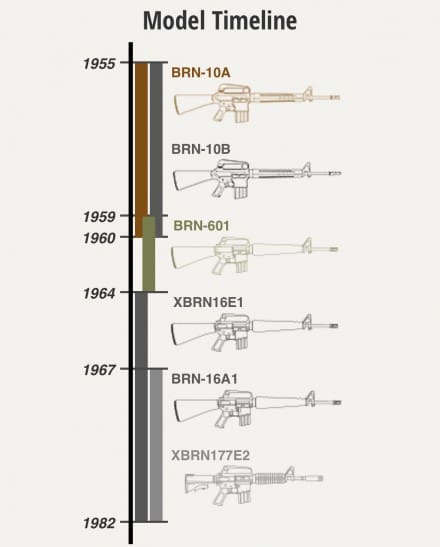

Available and shipping now, the 5.56mm models include:

BRN-16A1 (#078-000-402)

• Close copy of the iconic M16A1 first fielded in 1960s

• Matte gray anodized receivers to mimic originals

• Black furniture with period-correct contours

• Full fence M16A1 profile lower receiver

• 20” 5.56 lightweight M16A1 chrome-lined barrel with 1-12″ twist

• M16A1 Flash hider

• M16A1 bolt carrier group with phosphate finish and chrome lining

• Standard charging handle

• 20-round Brownells aluminum magazine

• $1,299.99 retail

BRN-601 (#078-000-400)

• Close copy of original USAF contract rifle with green furniture

• Matte gray anodized receivers to mimic originals

• “Slabside” lower receiver, without a magazine release fence

• As a result of no fence, front pivot pin is not captive

• Faux roll pin to retain buffer tube (only cosmetic on Brownells Retro)

• “Duckbill” early 3-Prong Flash Hider w/ split washer

• “Slickside” upper receiver without shell deflector or forward assist

• 20” 5.56 lightweight M16A1 chrome-lined barrel with 1-12″ twist

• M16 “Slickside” Chrome BCG w/o forward assist serrations

• Triangle 601 Charging Handle

• Brownells 20-round Waffle Magazine

• $1,299.99 retail.

XBRN16E1 (#078-000-401)

• Copy of transitional rifle between 601 and M16A1, with features of both

• Matte gray anodized receivers to mimic originals

• Black furniture with period correct contours

• Partial fence lower receiver

• 20” 5.56 lightweight M16A1 chrome-lined barrel with 1-12″ twist

• 3-Prong Flash Hider w/ split washer

• Faux roll pin to retain buffer tube (only cosmetic on Brownells Retro)

• M16 Chrome BCG with Forward Assist Serrations

• Modern charging handle

• Brownells 20-round aluminum magazine

• $1,299.99 retail

XBRN-177E2 (#078-000-403)

• An authentic copy of an early Special Forces carbine

• Matte gray anodized receivers to mimic originals

• Period-correct flash hider with grenade ring

• Period-correct furniture, including collapsible stock

• Full-fence M16A1 lower receiver

• 12.7″ 5.56 lightweight chrome-lined barrel with 1-12″ twist

• M16 Bolt Carrier Group with phosphate finish and chrome lining

• Standard charging handle

• Brownells 20-round aluminum magazine

• $1,299.99 retail

Brownells also announced the BRN-10, the first .308 rifle in its Retro Rifles™ line.

The BRN-10 will have the “trigger-style” charging handle in the top of the receiver, under the carry handle, and the same lines and contours as the first production AR-10®s from the 1950s.

With upper and lower receivers designed in conjunction with FM-Products, the BRN-10 is compatible with standard DPMS/SR25 components including triggers, magazines, barrels, bolt carrier groups, muzzle devices, buttstocks, pistol grips, handguards, and buffer assemblies.

It also features a newly-designed rear sight assembly with a peep sight adjustable for windage and elevation, with elevation setting viewable through the rear of the receiver.

Brownells is taking pre-orders now, with shipping slated for spring 2018.

The BRN-10 models include:

BRN-10A (#078-000-419)

• Close copy of early rifles, such as issued by Netherlands

• Chrome Retro BCG

• 20” fluted barrel in .308 with 5/8″-24 threads & 1-10″ twist, nitride finish

• Brown furniture including original-style handguard

• Open 3-prong flash hider

• BRN-10 receiver set machined from 7075 billet aluminum

• Custom bolt catch, takedown pins, selector and mag release to match retro style

• Not compatible with 308 PMAGs due to lower receiver design

• $1,699.99 retail

BRN-10B Brownells (#078-000-420)

• Close copy of late-model rifles, as adopted by Cuba and other nations

• Chrome retro BCG

• 20” lightweight barrel in 308 with 5/8″-24 threads & 1-10″ twist, nitride finish

• Black furniture including original style handguard

• Portuguese-style closed-prong flash hider,

• BRN-10 receiver set machined from 7075 billet aluminum

• Custom bolt catch, takedown pins, selector and mag release to match retro style

• Not compatible with 308 PMAGs due to lower receiver design

• $1,599.99 retail

In addition to complete Retro Rifles, Brownells also has offers a full line of Retro Parts, including 5.56 receivers, furniture, barrels and other parts. Retro parts in .308 will be available late in the year

To see both the Retro Rifles and Retro Parts, visit the www.brownells.com/retro.