Today, the Department of Homeland Security’s United States Secret Service Procurement Division released a solicitation for a new 5.56mm Rifle, for use in support of the USSS protective and investigative mission.

They will establish a five year Indefinite Quantity/Indefinite Delivery contract. However, they make this additional assurances:

The maximum lifetime quantity for this IDIQ shall be 3,900 rifles. The guaranteed minimum for this IDIQ is 500 rifles; the guaranteed minimum will be satisfied at the time of award with an initial delivery order. The minimum order quantity will shall be twenty-five (25) rifles. The maximum order quantity shall be 1,000 rifles.

Interested Offerors shall submit seven (7) samples of their proposed Rifle variant. Each sample shall be submitted with three (3) Magpul magazines (a total of 21 magazines) and all replacement parts and required tools in order to complete the manufacturer’s recommended maintenance up to 20,000 rounds (total of 7 maintenance kits). Each offeror may submit up to two (2) Rifle variants to be evaluated.

Characteristics:

The weapon shall be operable, without modification or alteration, by a right or left-handed user, firing with the right or left hand, depending on handedness.

All external metal parts of the weapon shall have a dark subdued, rust/corrosion resistant finish. The finish shall be unaffected by commercially available gun cleaning solvents, such as Simple Green, used in heated ultrasonic cleaning tanks. Flaking, peeling, blotching, etc. of the finish is unacceptable.

The weapon shall be chambered in accordance with current U.S. Military specifications for 5.56 x 45mm, and function with assorted ammunition ranging in weight from 55 to 77 grains (to include all common SAAMI-spec and Mil-Spec ammunition) as well as frangible ammunition.

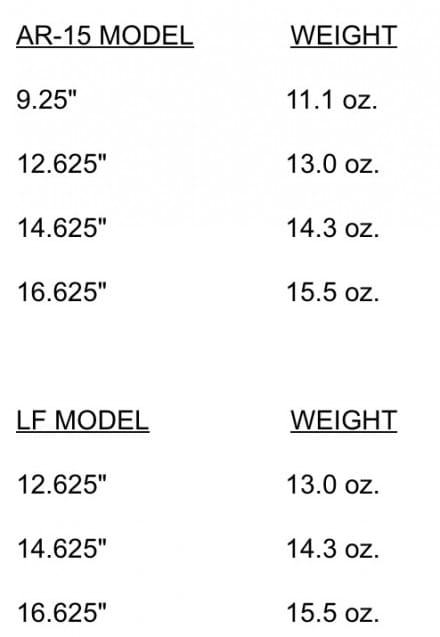

Dimensional Requirements:

Height (no taller than, sights folded, w/o accessories or magazine) 8.5 inches

Weight (no heavier than, w/o accessories) 7.5 pounds

O/A Length (no longer than, w/stock fully extended) 34 inches

Barrel length (min – max) 10-12 inches

Rifling (5.56) 1 turn 7” inch twist RH

Operating System.

The weapon shall utilize a direct-impingement gas-operated system or a short- stroke gas piston system.

Barrel.

The barrel shall have a minimum service life of 15,000 rounds.

Barrel service life is defined as a not exceeding 5 Minutes-of-Angle (MOA) and exhibiting no more than 125 ft/sec decrease in velocity (in accordance with USSS velocity testing procedures), with observance of offeror’s submitted maintenance protocols.

The barrel shall be free of cracks, seams, and other injurious defects and the bore and chamber shall be free of pockets, rings, bulges, and other deformations. The bore and chamber shall be chromium plated, or of equivalent corrosion resistance. Any coating in the chamber and bore shall be free of nodules, flaking, pits, stripping, anode burrs and evidence of etched base steel. Burrs and sharp edges shall be removed from the chamber edges, and bolt locking lugs.

The muzzle of the barrel should bear a thread size of 1?2” x 28 tpi, with shoulder geometry of

90 deg.

The muzzle should be equipped with a flash hider device, installed with shims as necessary.

Crush washers are not acceptable.

Mode of Fire. The weapon shall be selective fire, i.e. semi-automatic and full automatic. A “burst limiter” in the full-automatic mode is not acceptable.

Fire Selector.

The fire control selector shall be ambidextrous in design, and be a single lever paddle mounted on the side of the receiver, adjacent to the rear pistol grip, thereby not requiring the shooter to significantly break their firing grip when actuating.

The fire control selector shall be a rotary type and shall have three positions; safe, semi- automatic and automatic and shall rotate manually without binding from one position to another when the hammer is cocked. The selector shall remain in place in each position by a perceptible spring detent load until manually reset.

Trigger.

With the hammer cocked, when the selector is placed in the “SAFE” position, it shall prevent the trigger from releasing the hammer so that the weapon is incapable of being fired.

When the selector is placed in the “SEMI AUTOMATIC” position, it shall have a disconnect, so that the weapon is capable of semi-automatic fire only (one shot with each pull of the trigger).

When the selector is placed in the “AUTO” position, the weapon shall be capable of automatic fire (continuous firing until the trigger is released or all cartridges are expended) at a rate of no less than 600, and no greater than 900, rounds-per- minute, while utilizing M193 ammunition.

The trigger shall hold the hammer in the cocked position until the trigger is pulled. After partial or complete trigger pull, the trigger shall return to its normal forward positions (cocked and uncocked) under spring action.

The trigger pull shall not measure less than 4.0 pounds, nor more than 6.5 pounds, regardless if the fire selector is set on semi or full-automatic fire.

The trigger configuration shall be two-stage with no adjustment screws or set screws.

The trigger shall have a smooth face, cannot be wider than the trigger guard, and shall be the only control inside the area enclosed by the trigger guard. Any other controls (bolt catch/release, magazine/catch release, etc.) inside the area enclosed by the trigger guard are not acceptable.

While utilizing gloves, the trigger shall not pinch the trigger finger between the trigger and the side of the receiver or between the trigger and the inside bottom of the trigger guard. Any manipulation/modification to the trigger guard to meet this requirement is not acceptable.

Charging Handle.

The charging handle shall be situated in the upper receiver. The charging handle shall not reciprocate with the bolt when the weapon is fired. The charging handle shall be capable of being operated with one hand while the shooters other hand is grasping the pistol grip or forend grip.

Bolt Hold-Open Device.

The rifle shall be equipped with a magazine activated bolt hold open device. The bolt hold open device shall also be capable of being activated manually by the operator. When the bolt hold open device is activated by the magazine follower and the magazine is subsequently removed, the bolt shall remain in the rear or open position. When the bolt is in the rear or open position and a full magazine is inserted, the bolt shall remain in the rear or open position until the operator manually activates the bolt release. When the bolt catch is released, the bolt shall return to the battery position. Upon release, the bolt shall strip a round from the loaded magazine and load it into the chamber.

Magazine.

The weapon magazine well shall be compatible with the standard NATO STANAG 30 round M16 series magazine (NSN 1005-01-561-7200) and the Magpul PMAG 30 AR/M4, 5.56×45 Magazine (NSN 1005-01-628-5106 and NSN 1005-01-615-5169).

Only the Magpul PMAG 30 AR/M4, 5.56×45 Magazine (NSN 1005-01-615-5169; Mfr Part # MAG556) will be acceptable for solicitation submission and subsequent testing.

The magazine release shall securely retain the magazine in the magazine well. The magazine (whether empty or full) shall fall free from the magazine well once the magazine release button is activated without any further operator assistance. The magazine release button shall be spring loaded and the design of the receiver shall provide some shielding against inadvertent activation when placed against standard USSS uniform and/or body armor. The activation of the magazine release button shall be accomplished with minimum effort by the operator with only one hand.

The magazine should reliably feed all types of ammunition utilized in the USSS Evaluation and Testing protocols.

Magazines shall contain an anti-tilt follower that shall be able to activate the weapon’s bolt hold open device after the last round in the magazine is fired.

The magazine shall be capable of being inserted directly into the magazine well by the operator with one hand, and without any “rocking” type motion.

Lower Receiver.

The lower receiver shall have a permanently affixed plate, label, or laser- etching, displaying a QR code or barcode, readable via commercially-available optical reader. This code shall be embedded with information specific to the host firearm, including (but not limited to) make, model/variant, and unique serial number.

Upper Receiver.

The weapon shall be equipped with a Mil-Std-1913 Picatinny attachment rail on the top of the receiver for mounting of optics, iron sights, lasers, etc.

Forend/Handguard.

The weapon shall have a modular free-floating handguard assembly measuring no less than 9.0 inches of functional/configurable railspace (measured along the 6:00 o’clock position of the rail).

The handguard assembly shall have the ability to attach Mil-Std-1913 Picatinny rail segment along the length of the handguard at the 3:00, 6:00 and 9:00 o’clock positions simultaneously. The manufacturer shall provide a sufficient quantity of rail segments to cover the length of the handguard at the 3:00, 6:00 and 9:00 o’clock positions simultaneously. Handguards with permanently attached Mil-Std 1913 Picatinny railssections the length of the handguard at the 3:00, 6:00 and 9:00 o’clock positions shall also be considered.

When assembled to the weapon, the upper most rail of the free-floating handguard assembly shall align and be at the same height as the rail on the receiver. A one piece receiver/handguard assembly is acceptable as long as the barrel is free-floating, the above rail positioning interfaces are present, and handguard portion meets the minimum length requirement detailed in Section 2.

Pistol Grip.

The rear pistol grip shall be securely attached to the lower portion of the receiver and shall not interfere with the operation of the selector lever. If applicable to the submission, vendor shall provide interchangeable rear pistol grip adapters (backstraps).

Butt-Stock.

The butt stock shall be quickly adjustable for length of pull without the use of any tools. The butt stock shall have, at minimum total of four positions, including fully extended and fully collapsed.

Backup Sights.

When utilized, the front/rear ‘backup’ sights shall be viewable through an Aimpoint Model T2 while mounted on a suitable optic-specific commercially available sight mount.

The front sight shall be a folding locking type, capable of being locked in both the up and down positions (lever lock, friction lock, spring detent, etc.). The front sight shall be located at the front of the weapon either on top of the gas block or at the end of the rail on the hand guard. The front sight shall be a post profile type, adjustable for elevation as part of operator zeroing procedures. The profile of the sighting portion of the post shall be .050 to .075 inches in thickness. At no time shall the sight unlock from its position as a result of firing the weapon.

The rear sight shall be a folding locking type, capable of being locked in both the up and down positions (lever lock, friction lock, spring detent etc.). The rear sight shall be an aperture type, adjustable for windage and elevation as part of operator zeroing procedures. At no time shall the sight unlock from its position as a result of firing the weapon.

Sling Mount.

The weapon shall be supplied with means to mount a sling to, at minimum, the rear area of the receiver and the handguard, via quick-detach sling swivel. All sling mounting/attachment points will be required to be rotation-limited (4-position) quick-detach cups, to allow interface with quick-detach push button swivels.

Selection:

Interestingly, the weapon will be evaluated while wearing wearing Mechanix Wear Vent gloves.

Here’s some good news; any award will be made based on the best overall (i.e., best value) proposal that is determined to be the most beneficial to the Government, utilizing trade-offs, with appropriate consideration given to the following evaluation factors: Technical, Testing, Past Performance, and Price. All evaluations factors, other than price, when combined, are more important than price. Offerors are cautioned that the award may not necessarily be made to the Lowest Price offered or the highest rated submission.

Evaluation Criteria:

A. Technical/Testing

1. Phase One (Pass/Fail):

a. Technical Volume: The offeror’s technical volume will be inspected for compliance with the Instructions to Offerors and Statement of Work. (Pass/Fail)

b. Armory Level Inspection: The offeror’s submitted variant samples will each be inspected for compliance with the Statement of Work. (Pass/Fail)

c. Trigger Pull Test (Pass/Fail)

*The seven (7) samples will be randomly sorted into four groupings. (Exemplar, Sample Set A (3 samples), Sample Set B (1 sample), Sample Set C (2 samples))

d. Velocity Test – Sample Set A (Pass/Fail)

e. Accuracy Test – Sample Set A (Pass/Fail)

f. Rate of Fire Test – Sample Set A (Pass/Fail)

g. Rifle Drop Test – Sample Set B (Pass/Fail)

h. Firing Safety Inspection, Component Check, & Function Fire – Sample Set B

(Pass/Fail)

i. Armorer Repair and Maintenance Evaluation (Pass/Fail)

2. Phase

a. Basic User Live Fire Assessment

b. Special Operations Division User Live Fire Assessment

c. * Top 3 Ranked Variants will continue to Phase 3

Two – User Evaluation

3. Phase

a. Barrel Life Test (min. 20,000 rounds) (Pass/Fail)

b. Trigger Pull Test (Pass/Fail)

c. Velocity Test (Pass/Fail)

d. Accuracy Test (Pass/Fail)

e. Visual/Mechanical Function Test (Pass/Fail)

f. * All weapon malfunctions will be recorded and inspected by USSS Armorers.

Only weapon-caused malfunctions will be used in the evaluation.

Three – Reliability and Endurance Testing – Sample Set A

Deadlines:

Questions: October 31, 2017 1600 EST

Responses: December 1, 2017 1600 EST

Full details at a www.fbo.gov.