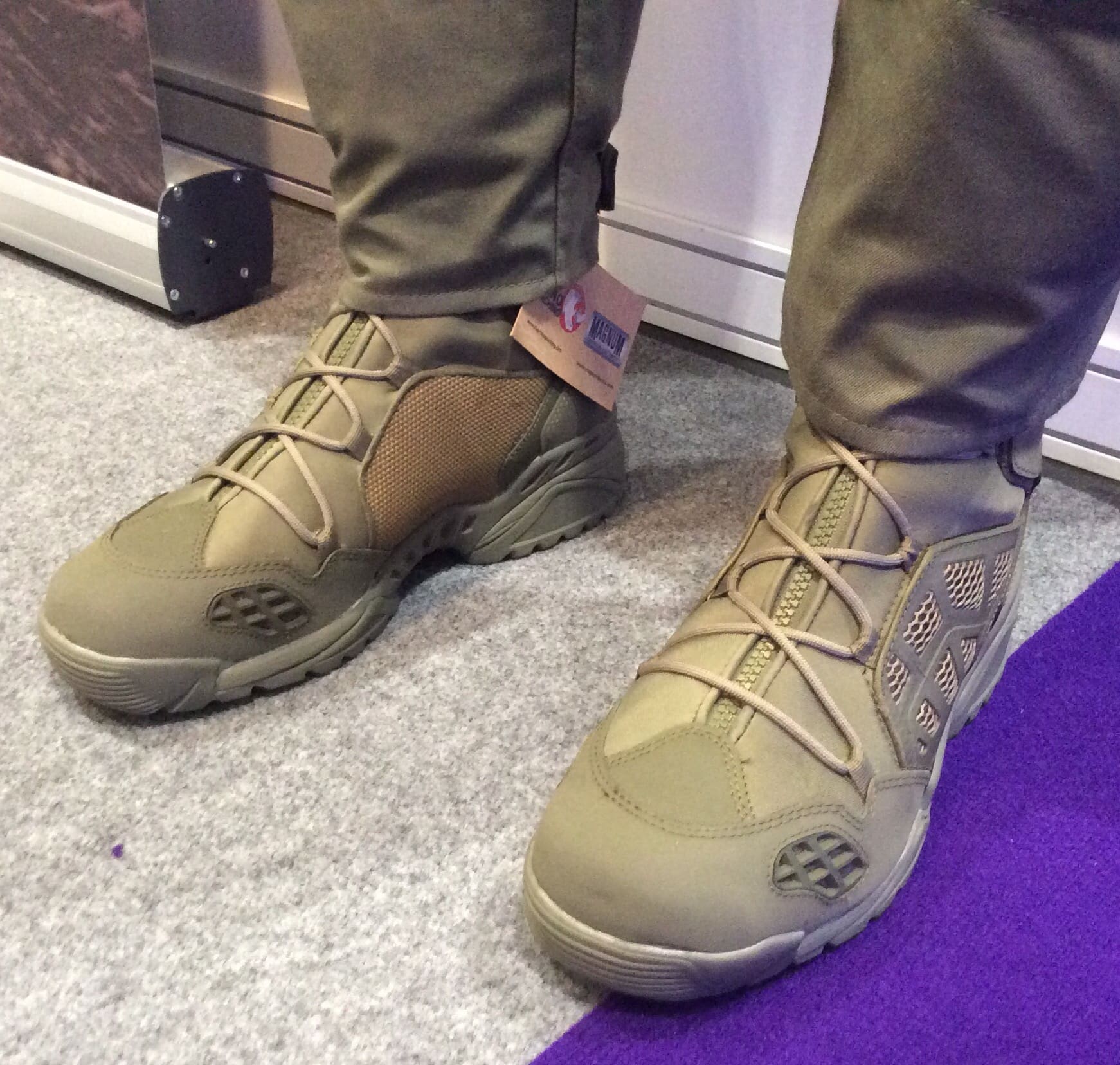

The title pretty much sums it up. The Lowa Task Force Innox GTX Mid is coming early next year in MultiCam. A French customer has already placed an order and they will be available to European customers. There are currently no plans to bring these into the US. Rather a “digital camouflage” model will offered in the US instead. The boot is currently offered in Black and Coyote.

The Innox incorprates a Gore-Tex lining, a PU injected midsole with their proprietary PU Monowrap frame construction for stability along with the NXat sole unit for traction and stability.