Spartan Blades of Southern Pines, NC today announce a new a new Poros folding knife as part of their Bronze Grade line of knives.

Spartan Blades, a Southern Pines, NC based company, is an award-winning maker of premium cutlery. The new “POROS” folder was designed by retired Special Forces Soldier Curtis V. Iovito of Spartan Blades.

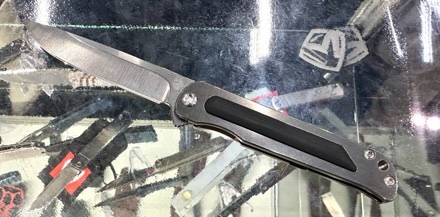

The POROS flipper, was designed by Curtis Iovito as a robust and full-sized flipper. This blades high grind lines combined with a sharp piercing drop point make it a trusted companion for everyday carry. Its quick flipper action is assisted by IKBS Bearing for the ‘Snap” you are looking for! Its distinctive scallops are not only beautiful but provide for a sure grip. The deep carry pocket clip maintains a low profile while keeping your blade ready when needed. The blade is 154CM stainless steel with black titanium nitride coating; SS hardware and liner have black electro-deposit powder coating.

Release date June 25, 2023 (MSRP $180.00)

spartanbladesusa.com