RESEARCH TRIANGLE PARK, N.C. — Understanding the split-second decisions squirrels make as they jump from tree branch to tree branch will help scientists develop more agile robots.

With funding from the U.S. Army, researchers at University of California, Berkeley studied how squirrels decide whether or not to take a leap and how they assess their biomechanical abilities to know whether they can land safely.

Understanding how squirrels learn the limits of their agility could help scientists design autonomous robots that can nimbly move through varied landscapes to help with military missions such as traveling through the rubble of a collapsed building to aid in search and rescue or to quickly access an environmental threat.

“The team at UC Berkeley is challenging the comfort zone of today’s robotic design in a very clever way, taking us one step closer to tomorrow’s truly autonomous and versatile robots,” said Dr. Dean Culver, program manager for Complex Dynamics and Systems at the U.S. Army Combat Capabilities Development Command, known as DEVCOM, Army Research Laboratory. “Studying organisms’ behavior, like jumping squirrels, lets the engineering community ask fascinating questions about an autonomous agent trying to navigate an uncertain environment. For example, what stimuli cause learning? How does the interplay between structural compliance in a limb and surprises in an environment permit adjustments during a maneuver?”

To tackle these questions, Dr. Robert Full, professor at UC Berkeley and former doctoral student Dr. Nathanial Hunt, now an assistant professor of biomechanics at the University of Nebraska, Omaha, joined forces with professor of psychology Dr. Lucia Jacobs and former UC Berkeley doctoral student Judy Jinn.

Jacobs and her students developed precise methods to study cognition in wild campus squirrels, and they proposed integrating these studies with biomechanics, extending Full’s laboratory models not only to mammals for the first time, but to a wild mammal–squirrels–that had experienced the full natural development of its agility.

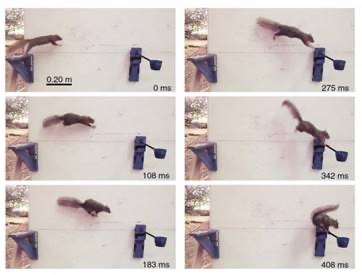

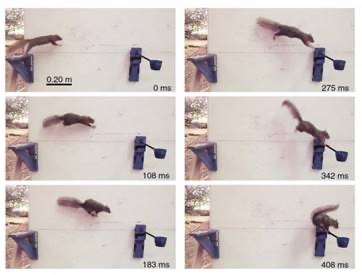

In the journal Science, the researchers report on their experiments on free-ranging squirrels, quantifying how they learn to leap from different types of launching pads–some bendy, some not–in just a few attempts, how they change their body orientation in midair based on the quality of their launch, and how they alter their landing maneuvers in real-time, depending on the stability of the final perch.

“As a model organism to understand the biological limits of balance and agility, I would argue that squirrels are second to none,” said Hunt, now an assistant professor of biomechanics at the University of Nebraska, Omaha. “If we try to understand how squirrels do this, then we may discover general principles of high-performance locomotion in the canopy and other complex terrains that apply to the movements of other animals and robots.”

Researchers conducted the experiments in a eucalyptus grove on the UC Berkeley campus, where the Berkeley team enticed fox squirrels that roam the campus into sketchy situations where they had to decide whether to leap for a peanut or let it go.

They found that, as expected, the flimsier or more compliant the branch from which squirrels have to leap, the more cautious they were. But, it took squirrels just a few attempts to adjust to different compliances.

“When they leap across a gap, they decide where to take off based on a tradeoff between branch flexibility and the size of the gap they must leap,” Hunt said. “And when they encounter a branch with novel mechanical properties, they learn to adjust their launching mechanics in just a few jumps. This behavioral flexibility that adapts to the mechanics and geometry of leaping and landing structures is important to accurately leaping across a gap to land on a small target.”

The squirrels don’t balance the bendiness of the launching branch and the gap distance equally. In fact, the compliance of the branch was six times more critical than the gap distance in deciding whether to jump.

This may be because squirrels know that their sharp claws will save them if they miscalculate. Their claws are so failproof, Hunt said, that none of the squirrels ever fell, despite wobbly leaps and over- or undershot landings.

“They’re not always going to have their best performance–they just have to be good enough,” he said. “They have redundancy. So, if they miss, they don’t hit their center of mass right on the landing perch, they’re amazing at being able to grab onto it. They’ll swing underneath, they’ll swing over the top. They just don’t fall.”

That’s where exploration and innovation come into play as squirrels search for the best leaping strategy.

“If they leap into the air with too much speed or too little speed, they can use a variety of landing maneuvers to compensate,” Hunt said. “If they jump too far, they roll forward around the branch. If they jump short, they will land with their front legs and swing underneath before pulling themselves up on top of the perch. This combination of adaptive planning behaviors, learning control and reactive stabilizing maneuvers helps them move quickly through the branches without falling.”

One unsuspected innovation was that during tricky jumps, squirrels would often reorient their bodies to push off a vertical surface, like in human parkour, to adjust their speed and insure a better landing. Parkour is a sport in which people leap, vault, swing or use other movements to quickly traverse obstacles without the use of equipment.

“Learning from squirrels the limitations of improvisation with a given controller architecture and compliant actuators will help engineers understand how to design a robot controller and actuators to maximize improvisational capabilities,” Dean said. “To get to that next step for more agile robots, we first have to observe and quantify the ideas of adjustment and improvisation, which this research provides.”

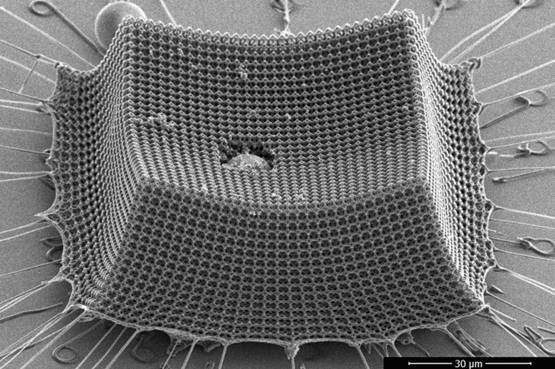

This research complements earlier Army-funded research at UC Berkeley that developed an agile robot, called Salto that looks like a Star Wars Imperial walker in miniature and may be able to aid in scouting and search-and-rescue operations.

In additional to the Army, the National Science Foundation and the National Institutes of Health supported this research.

By U.S. Army DEVCOM Army Research Laboratory Public Affairs