FORT IRWIN, Calif. — On the beaches, oceans, air and deserts of the U.S. West Coast, more than 4,000 members of the joint force, civilians, contractors, and militaries from the United Kingdom, Australia, Canada, New Zealand, France and Japan experimented with more than 200 technologies in the Army’s largest experiment in the dirt, Project Convergence Capstone 4.

Two phases, primarily conducted in California at Camp Pendleton and the National Training Center, allowed experimenters to work in arduous conditions and experiment with cutting-edge technology in as close to a real-world environment as possible. Distant locations also supported the experiment up and down the West Coast and the Pacific region to experiment through time, distance and complexity.

Technology getting to PC-C4 itself takes time and goes through a review process designed to save PC-C4 time and money by ensuring only the most promising technologies make their way to the capstone experiment. All technology at PC-C4 could fill a potential gap or provide a capability designated as necessary by senior leaders. Nascent technologies go through the Science Technology and Review Board before spending time at a myriad of other experiments and lab-based risk reduction activities, all before they ever make their way to NTC or Camp Pendleton.

“There are plenty of technologies we find out aren’t mature enough or don’t fill a gap or capability the way we thought, so they get withdrawn way before Capstone 4 takes place,” said Mindy Gabbert, experiment division chief at the U.S. Army Combat Capabilities Development Command.

Not only does this scrutiny save money and time once the experiment begins at PC-C4, but it also ensures that all players involved in putting on PC-C4 already have working relationships.

“It’s not just a yes or no process. It’s going through those prior risk reduction activities that allows the broader community to see those technologies and just to be familiar with them before they get here so that they can properly fit them into the exercise, so that they can make sure that we are aligning them with the right use cases and the other right opportunities out here,” Gabbert said. “So, in addition to the technical aspects of those technologies, it’s just building that knowledge base within the community of what’s out there and bridges that community by building the whole body of knowledge we’re all working on.”

Since 2020, Project Convergence (PC) has grown exponentially in scale and scope. PC-C4 was the largest PC experiment yet, with participation from the United States Army, Navy, Marine Corps, Air Force and multinational partners.

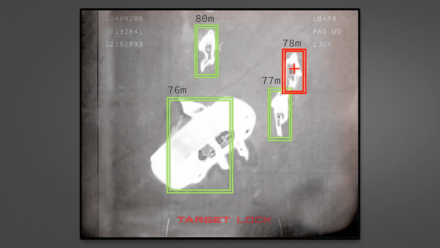

“The first PC was conducted in 2020. It was Army only and focused on a specific time between the identification of a target and an effector shooting on that target,” said Lt. Gen. Ross Coffman, United States Army Futures Command deputy commanding general. “And from there, we decided the Army will never fight alone, so let’s get the entire joint force focused on this problem set.”

“This year, we have increased the threat envelope to 10 times what we did last year. With the entire joint force and our U.K. and Australian teammates and allies, we were able to effectively move data for the first time in an Indo-Pacific scenario at a magnitude we’ve never seen before,” Coffman said.

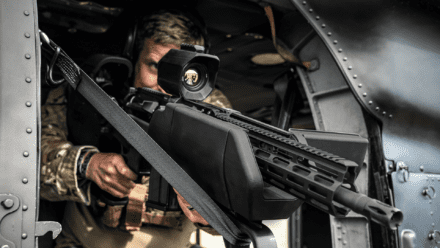

PC-C4 informed combined, joint all-domain situational awareness, command and control, integrated offensive and defensive fires, defeat large target array, human machine integration and how to sustain the force over large-scale combat operations, dubbed contested logistics.

One of the significant successes of PC-C4 was the integration of sensors and fires to ensure that the force is best able to stop incoming missiles without depleting munitions unnecessarily. Coffman explained that they used offensive and defensive fires to tackle the problem and ensure that sensors have interoperability between the branches to ensure the right sensors pick up the threat and the right shooter takes it out, so the military does not waste munitions.

“It’s not our job to go fill up the magazines to the level we’d like them to be, but it is our job to ensure that we can connect my sensors to his fires and his sensors to my fires because I might have the most available weapon where he’s got the most survivable sensor and vice versa,” said Vice Adm. Michael Boyle, Third Fleet commander. “And that’s really what this is about; it’s enabling us to pick from whatever magazine we need.”

Another major win for PC-C4 was the increased ability to push data through a fully networked command, control and communications system. This allowed for more significant amounts of data to be pushed to the Joint and Allied forces.

“When you put stress on untested equipment, you’re going to learn things,” Coffman said. “One of the interesting things is that as we increase the pipe on this cross, it worked magnificently. It could pass a large amount of data that we had not seen before we tested it last year, and we could see it was nascent. We were able to pass data successfully.”

Great strides in contested logistics experiments also took place across both phases. Experiments involving beach landings, drones and printing technology were showcased, and for the first time, a repair part for an Army system was printed out at sea on a Navy vessel.

“Envision the printer was on the vessel,” said Col. Shane Upton, director of the Contested Logistics Cross-Functional Team. “They printed the part, we put it on an unmarried unmanned aerial system, a drone, and flew it onto the beach to the point of need. In a contested environment where you don’t have a permissive flow of sustainment, you’ve got to use some of these exquisite technologies. That’s why we’re experimenting with them.”

Now that PC-C4 has wrapped up after several weeks of experimentation, the data collected will be analyzed to inform future acquisition and force structure decisions and aggressively advance and integrate Army contributions to the Joint and Combined fight.

“It’s worth every penny,” Coffman said of the experiment. “The readiness of the joint force and the partnership with our allies is invaluable. When called upon, the women and men of this nation and the women and men of other nations will fight side by side to preserve liberty, and that cost is worth every penny.”

By Matthew Murch, Futures and Concepts Center