Continuing its tradition of supplying the U.S. Military for more than 55 years

June 27, Greensboro, NC – Burlington Industries LLC, a division of Elevate Textiles, is proud to announce it will supply wool blended fabrics for use in the newly-updated Army Green Service Uniform, specifically the jacket, tie, and bottoms. These fabrics will be produced at the company’s facilities in Raeford and Cordova, North Carolina.

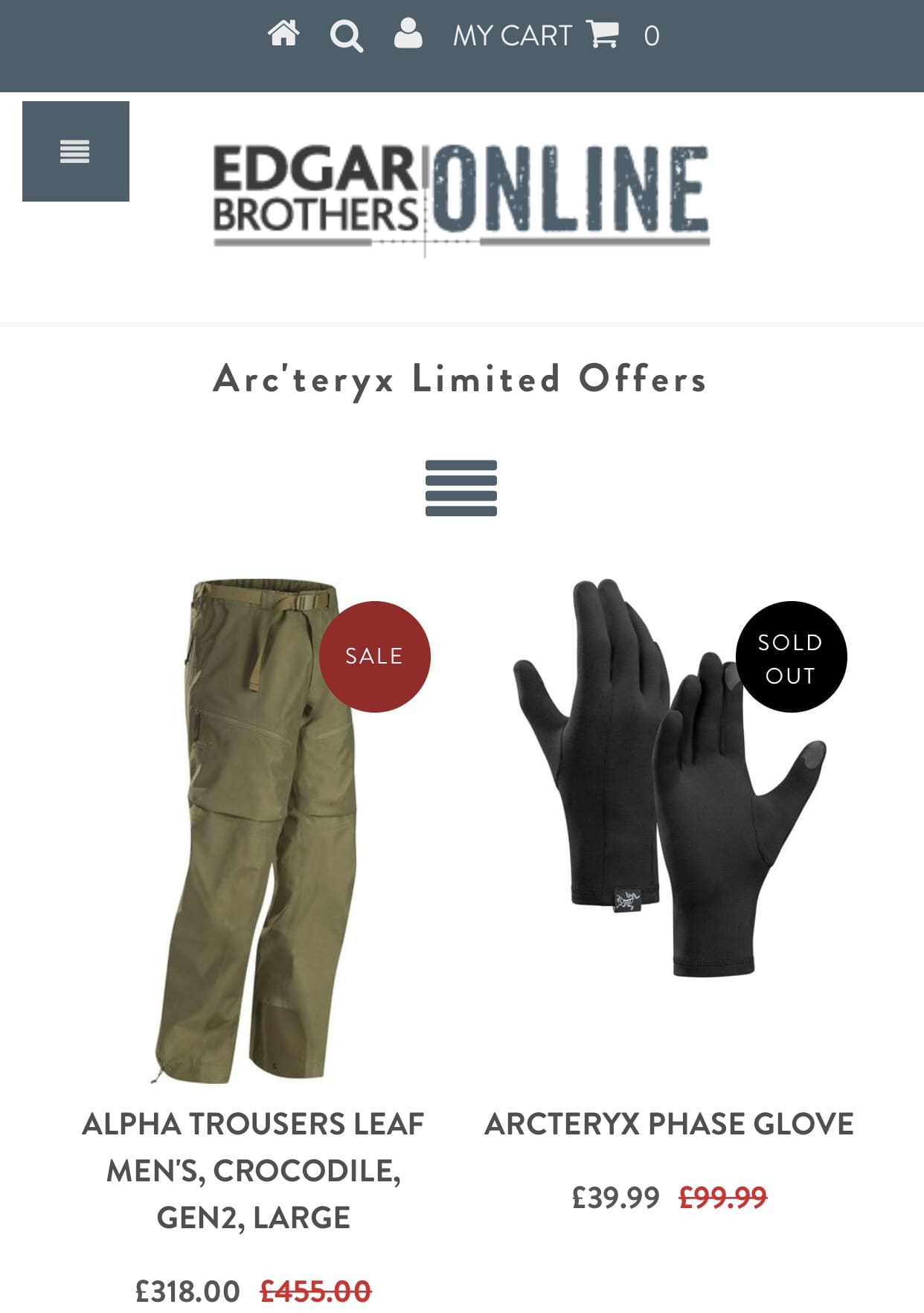

US Army photo of new Army Green Service Uniform

Burlington is honored to be an integral part of the defense supply chain for over 55 years. The development of the new Army Service Uniform fabric has been underway for over two years in partnership with the Defense Logistics Agency (DLA), the United States Army, and several private industry partners. Continuing in the Burlington tradition, the entire process has focused on one core concept – serving the men and women of the United States Armed Forces.

These new fabrics allow their wearers the confidence to be their best with unmatched comfort, durability, colorfastness, and appearance as they represent the best of our nation both at home and abroad. Burlington’s Raeford operation is known for superior consistency and color continuity, which is a requirement for a force as large and diverse as the United States Army. Skilled workers, many with more than 20 to 50 years of experience, carefully tend to each process, ensuring the yarn and fabric are produced to meet the highest quality standards.

“At Burlington, we honor our public servants with a dedication to quality and innovation, to make sure those who serve are always served by the garments they wear,” says Allen Smith, President of Burlington. “Our Raeford brand of worsted wool fabrics are engineered to provide the soldier with advanced durability, comfort, and wrinkle-resistance, and provide Burlington’s unmatched color capability to ensure each uniform issued matches over the span of many years. As our nation prepares to celebrate the anniversary of its independence, we are honored to see the new Army Green Service Uniform in action and to pay tribute to the men and women who protect our freedoms each day.”

Since 1923, Burlington has been a global textile leader with core competencies in worsted wool and performance synthetics and has been an integral part of the defense supply chain for more than 55 years. Offering a diverse range of vertical manufacturing capabilities, fiber, and fabric blends, Burlington® Military is proud to provide quality fabrics for United States Military personnel. Through innovation, Burlington’s in-house Research and Development department, Burlington Labs®, engineers advance fabrications and technical finishes that are applied to protect and enhance performance while providing troops protection, easy-care, and advanced comfort in all their diverse environments.

Burlington Military combines the resources from the Burlington, Safety Components, and Carlisle business units to create an extensive military products platform of diversified fabrics developed to service the specific needs of the military market. Products include fabrics for Class A dress uniforms, camouflage combat and utility uniforms, physical training and extreme cold weather wear, flame resistant and firefighting protective clothing, high performance equipment, ballistic fabric for body armor and load carrying equipment, and other specialty items.

About the Army Green Service Uniform

Previously referred to as “pinks and greens,” the new uniform is inspired by World War II-era uniforms. These new uniforms are expected to be adopted Army-wide by 2020.

The current Army Blue uniform will now serve as a formal dress uniform and the Army Green uniforms will become the day-to-day uniforms for soldiers. The Army’s combat uniform, Operational Camouflage Pattern, which is produced in part at Burlington’s Carlisle Finishing facility in South Carolina, will continue to be their duty day and field day uniform.

About Burlington

Celebrating over 95 years of textile leadership, Burlington is a global diversified provider of textile solutions across performance & specialty apparel fabrics, active wear, advanced uniform fabrics, and technical fabrics. Burlington operates as part of Elevate Textiles, Inc. with worldwide operations in the United States, Mexico, and China. Elevate Textiles’ business units include: American & Efird, Burlington, Cone Denim, Carlisle, Gu?tterman, and Safety Components. To learn more visit www.burlingtonfabrics.com; www.elevatetextiles.com or follow us at @burlington1923.