MARINE CORPS BASE CAMP LEJEUNE, N.C. – Amidst the Department of War’s “Drone Dominance” intent to acquire 300,000 one-way attack drones by calendar year 2028, 2nd Marine Logistics Group has developed the Marine Corps’ first National Defense Authorizing Act-compliant 3D printed drone. The drone, titled HANX, is a holistically adaptable approved platform that can be tailored to the needs of the warfighter. HANX marks a large leap from previous Marine Corps’ 3D printed drone capabilities, such as “nibbler” in 2017, which was not subject to the same compliance requirements that exist today to meet NDAA requirements. HANX being fully NDAA compliant means it is resilient to backdoor programs from our adversaries, making it a device that can be used by any Marine for their mission. U.S. Marine Corps Sgt. Henry David Volpe is behind the creation of the 3D printed drone platform, helping to bring the Marine Corps into the next era of 3D print capabilities.

Volpe, an automotive maintenance technician with 2nd Maintenance Battalion, 2nd Combat Readiness Regiment, 2nd MLG, started 3D printing in seventh grade in his home state of Missouri. He joined a Lego robotics club in middle school, where he found he enjoyed making robots from putting the pieces together to programming them.

“Both my parents are engineers, so I feel like I’ve always had that encouragement to tinker and experiment with things,” said Volpe. “Programming and designing things were just a natural continuation of my interest and the environment I grew up in.”

After graduating from high school, Volpe attended college for automotive maintenance technology, where he learned how to work on cars and even got a job as a car mechanic.

“I just enjoyed the labor and learning about the systems within a vehicle. More specifically, I loved the electronic side of automotive. Yes, the part everyone complains about,” said Volpe.

However, when COVID-19 hit in 2020, it made both work and school hard for Volpe. He needed stability, so he thought of the armed forces. Volpe said he always thought that Marines were the best of the best, so he saw this as not only a good opportunity to join for job security, but a good excuse to become one of America’s finest.

After graduating from boot camp and his military occupational specialty schoolhouse in 2022, Volpe began working as a motor transport mechanic at 2nd Maintenance Battalion, where he pursued his passion for working on and maintaining cars. One day, a friend from work told him about the opportunities in robotics, 3D printing, and advanced manufacturing that the II Marine Expeditionary Force Innovation Campus offers.

Volpe was immediately intrigued by the opportunity. His previous experience with robotics and 3D printers made the innovation campus appeal to his passion and provided a chance to get back into an old hobby. Conveniently, the campus was also right across the street from his job, so he decided to go over and get involved.

“I immediately went over to the innovation campus, shook hands with the master sergeant, and said, ‘I want to work over here, I’ve got experience with this,’” said Volpe.

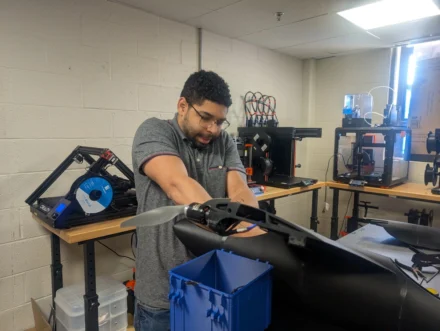

The innovation campus was launched with the intention of teaching and training Marines in 3D printing, robotics, and manufacturing. It provides a space for technically proficient and curious Marines to learn new skills as well as gain access to the materials, software, and hardware to design any products they can think of. Once Volpe got there, he was put to work immediately, where he repaired two 3D printers that had the crew stumped. His college experience helped him diagnose the issue and develop a problem-solving mindset. Volpe quickly found himself feeling at home working in the innovation campus.

“Although the environment itself felt surreal to me, I had never envisioned getting to do what my hobbies are as a job,” said Volpe. “Especially within the Marine Corps.”

Chief Warrant Officer 3 Matthew Pine, the officer in charge of the innovation campus, came across an article online about the U.S. Army making its own 3D-printed drones and decided to check it out. Pine knew Volpe was interested in drones because he had built them on his own time. So, Pine and Volpe took a trip to U.S. Army Fort Campbell, Kentucky, where Volpe was inspired to create a better and cheaper 3D printed drone platform designed and built entirely by a Marine.

“Their drone has some capabilities mine doesn’t, and some very nice cameras with it, but what I saw was a big price tag. I knew I could make something far cheaper without sacrificing too many features,” Volpe said. “The [U.S. Army] design and hardware selection was also contracted out to third and fourth parties; making their 3D printed drone an assembly can’t be entirely done by soldiers.”

Once Volpe set his mind to it, Pine helped lead Volpe and the rest of the Innovation Campus team through drone development, guiding them to reach their ambitious goal of innovation throughout the Marine Corps while giving them the room to make their own decisions.

Volpe previously built drones from kits but had never fully 3D-printed and built one from the ground up. He decided the same week he got back from this trip to take on the challenge and make the Marine Corps their own in-house-made drone.

Due to the operational tempo of the Innovation Campus, Volpewas given a deadline of 90 days to get the job done. He worked around the clock to design the drone, using different parts to make a Frankenstein of a prototype simply called “HANX,” based on Volpe’s nickname “Hank.” Before this challenge, Volpe only worked on drones by fixing or modifying them to suit whatever he needed his drone to do. It had been a while since he had built an actual drone. Despite this, he succeeded and made the drone he set out to build. Volpe had created five major versions of HANX in total prior to finishing the final prototype and there were dozens of small adjustments made to keep improving its design throughout the process.

“This was only possible because of the collaboration with the team around me,” said Volpe. “I’d give out different drone parts and say, ‘Hey, can you redesign this for me?’ Or ‘I need 20 of these printed.’ I designed it, but I didn’t work on it alone.”

Volpe took the lead on this project, assisted by Cpl Liam Smyth, who made the first design for HANX’s landing gear, Staff Sgt. Jonathan Borjesson, who helped Volpe with the hours of tuning the drone to the correct specifications, Cpl. Isauro Vazquezgarcia and Cpl. Corven Lacy who kept the 3D printers running while Volpe worked on the drone design and provided design input to improve the drone. None of it would have been possible if it were not for Chief Warrant Officer 3 Pine, who helped with the policy changes to even allow the drone to be made.

“You never do anything alone, whether that’s in combat or not,” said Volpe. After meticulously researching, planning, and implementing new knowledge learned to draft his blueprints, hundreds of hours, late nights, early mornings, failed designs, and shared success, the team of Marines had brought the drone from an idea to reality. And now “HANX” was ready to be tested.

Even after spending over 1000 hours, the hard part was still ahead. Now the team had to see if their work would meet the rigorous requirements to be approved by the small unmanned aerial systems program office.

“Anyone can create a cheap drone using cheap non-approved parts; however, finding parts that don’t run the risk of having backdoor software is difficult,” said Volpe.

A device harboring backdoor software is a device that adversaries could easily hack to record data from. To prevent the drone from becoming a potential security risk, all the critical components inside the drone have to be NDAA compliant.

“I was doing a ton of research, finding different manufacturers and then messaging them, trying to get a hold of people and talk with them about what they’re selling, and making sure that it is within NDAA standards,” said Volpe.

Volpe applied himself to finding all the pieces that would hopefully meet the necessary standard, the back and forward with the U.S. government a difficult but necessary process as they ensured all the pieces used were NDAA complaint. And then came the final test, ensuring the final product as a whole met all the necessary changes and adaptation requirements. The team waited eagerly, months of focused work balancing on the edge of success or failure.

But then the call came from the program office at NAVAIR notifying the team of the interim flight clearance process changes that enabled approval for flight of HANX. Just like that, Volpe had built the first NDAA and NAVAIR approved 3D printed drone. Completely by Marines, for Marines, at a price point that added versatility across units and changed the game on the limits of sUAS capabilities.

“I had never accomplished something like this,” said Volpe. “I’ve been to college before, rebuilt engines, but this is mine. This is what I designed. This is what I made”

After finally getting HANX approved for use, the Innovation Campus developed a plan for in-house-built, 3D printed modular drones. All the work put in over the past few months by Volpe and the team was now captured in training plans and a draft course framework. The campus was preparing the Marine Corps to equip any Marine with the ability to sustain the capability offered by the HANX and the equipment to manufacture it across all units. A capability quickly taken advantage of by the Marine Corps Special Forces Command at Marine Corps Base Camp Lejeune.

With HANX’s ability to be modified to suit various types of missions, such as reconnaissance, logistics, one-way attack drones, and more, it was a real-time answer to needs across II MEF major subordinate commands. With the Secretary of War’s intent for proliferating drone technology, HANX ability to adapt and be easily and cheaply crafted by any Marines in any unit directly supports the War Department’s plan to “unleash American drone dominance by bolstering the U.S. drone manufacturing base. HANX provides the Marine Corps large potential in harnessing the ingenuity of warfighters, arming combat units with low-cost attack drone capabilities, and training senior officers to overcome bureaucratic risk-aversion culture in drone procurement and training.”

“Some explosive ordnance disposal Marines, are about to buy 20 of these, and they’re going to be strapping explosives to it,” said Volpe, “The drone is cheap and easy to change, making it easier to be utilized for a variety of missions throughout the military, compared to all of the drones bought through contractors where we aren’t allowed to modify them.”

“When I first started working with 3D printing, I never could have imagined the technology would advance enough to enable anyone to be able to 3D print a drone,” said Volpe. “But seeing myself design and make one for the Marine Corps, a year ago I wouldn’t have thought that was possible.”

Volpe’s HANX drone is the most significant leap in 3D-printed drone technology for the Marine Corps in almost a decade and a significant accomplishment for the II MEF Innovation Campus and the U.S. Marine Corps as a whole.

“Volpe’s put over 1000 hours in this Innovation Campus workspace,” said Pine. “He’s very knowledgeable. He dives in deep whenever he’s learning something new. He is a motor transport mechanic, and he made the first drone approved for flight. That should tell you enough about how driven he is to make things successful.”

However, the HANX drone is just a stepping-stone on the road to the campus’s goal to enhance manufacturing capabilities in the Marine Corps. Innovations like HANX show Marines of all ranks and backgrounds they can embrace the 3D printing invocation that is being entirely done by Marines, for Marines. What started as a friend’s off-handed comment and a handshake, turned into one Marine’s passion impacting thousands.

Story by LCpl Javier Santillan

U.S. Marine Corps Forces, Europe and Africa