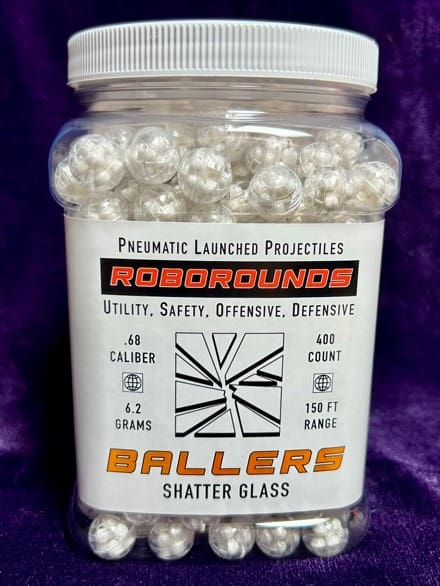

HOP Munitions is proud to announce the exclusive launch of the revolutionary Baller .68 caliber projectiles, a groundbreaking advancement in less lethal ammunition. Engineered in partnership with Roborounds, these projectiles address a critical gap in law enforcement operations by combining enhanced glass-breaking capabilities with an OC agent or UV Marker.

A Tactical Game-Changer for Law Enforcement

In high-stakes situations like barricaded suspects or crowd control, reliable less lethal options are essential. Standard polymer rounds often fail to break through tempered auto glass, leaving officers at a tactical disadvantage. The Baller projectile shatters these limitations—literally. With the ability to break tempered auto glass from up to 50 yards, these projectiles deliver precision and performance unmatched by conventional .68 caliber rounds.

“Baller projectiles are designed to bridge the gap between safety and effectiveness. We’re committed to equipping law enforcement with tools that ensure control while minimizing risk to everyone involved.”

Innovative Features That Redefine Performance

Baller projectiles stand apart thanks to the following:

- Unmatched Glass-Breaking Ability: Penetrates tempered auto glass at 50 yards using a standard .68 caliber launcher at 240–300 fps.

- Reduced Penetration Risk: Designed to mitigate harm after breaching glass, ensuring the safety of individuals inside the vehicle.

- Optional Dual-Action Payloads: Can deliver OC powder or UV marking agents for swift de-escalation post-barrier breach.

- Seamless Integration: Fully compatible with existing .68 caliber launchers, making adoption easy for law enforcement agencies.

Addressing Tactical Challenges with Confidence

Baller projectiles enable law enforcement officers to respond confidently, from vehicle barricades to volatile crowd control scenarios. Their precision minimizes collateral damage, and their innovative payload options streamline operational efficiency.

“By offering a safer, more effective solution for glass-breaking scenarios, Baller projectiles provide agencies with a critical tool to enhance their response capabilities.”

Availability

Baller .68 caliber projectiles are available exclusively through HOP Munitions. Agencies seeking to equip their departments with these projectiles should contact max@hopmunitions.com for more details.