W.L. Gore & Associates (Gore), creators of the GORE-TEX Brand and global leader in high-performance waterproof, windproof, and breathable fabric technologies exhibited several new products including the Tropo Performance All-Weather Active Insulation Jacket.

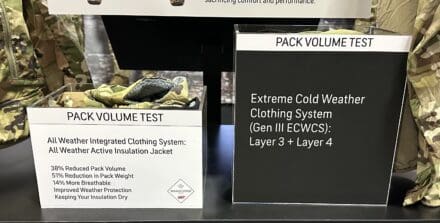

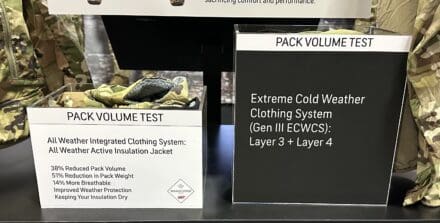

Developed in-house, the proposed All-Weather Active Insulation Jacket is intended to replace both Gen III ECWCS levels three and four in the Soldier’s rucksack (seen below).

It’s a straight forward design sized to both under armor and as a stand-alone jacket and delivers active breathability during high-output use and static warmth when stationary, keeping the insulation dry from the inside and out. There’s plenty of ventilation for high activity with Targeted Ventilation Underarm panels and mesh pocket bags promoting airflow during aerobic activity. Speaking of pockets, there are five with three external and two internal pockets. Ready for use, it offers Velcro options for name/rank placement on sleeve or chest.

The shell material is WINDSTOPPER fabric which delivers:

• High resistance to air penetration to block the wind and maintain consistent warmth

• Fends off light rain and snow while maintaining insulation performance/protection

• High moisture vapor permeability allows Soldier’s perspiration to escape during periods of high activity

• Outer shell fabric sheds moisture even without DWR

Inside, Polartec Alpha Direct insulation delivers:

• High-efficiency warmth with superior compressibility to reduce bulk

• Extremely open structure to increase airflow and prevent overheating during high activity

• High moisture wicking capability to quickly pull moisture off the Soldier’s body

Between going from two garments to one and with these materials, the jacket educes weight by 51% and pack volume by 38.8%.

The materials also keep insulation and base layers dry in adverse weather while maintaining breathability and comfort (low water pick-up). A 14% improvement in moisture vapor transmission vs ECWCS L3/L4.

Aside from its volume advantage, All-Weather Active Insulation Jacket meets the visual and nIR requirements of the OCP camo pattern (option to include SWIR), unlike the ECWCS L3 Fleece.

Submitted for formal evaluation under the Soldier Enhancement Program, it has been deferred to the next board for consideration. Previously, examples have been wear tested by several Army units in relevant field conditions.