This image at AUSA from Aimpoint claims that the 6x magnifier is coming but I’ve got a feeling it’s really only just breathing hard.

This image at AUSA from Aimpoint claims that the 6x magnifier is coming but I’ve got a feeling it’s really only just breathing hard.

Revision Military has developed an interesting thermal signature management shroud using the Milliken Conceal fabric.

It uses a magnetic interface to keep it in place around eyepro. They’ve also created internal standoff around the nose and mouth to suppress hot spots created from exhalation.

The F5032 Lightweight Night Vision Binocular weighs just under 500 grams. It also offers close focus with clear images as close as 9″.

The F5032 fixed or adjustable diopter.

Powered by a single AA, the F5032’s Gen 3 image intensifier tube is servicable at the unit level and offered in White or Green Phosphour. The tubes are autogated which will adjust to high light levels and won’t shut off inadvertendly. It also features vertical viewing ability and won’t shut off when you look up.

Each monocular in the F5032 can be individually flipped up, out of the way.

I like the switch which is a simple detent for on/off.

The WL Gore flexible membrane material formerly known in development as ‘Topo’ has officially been named GORE-TEX Fabric with Stretch Technology.

In addition to jackets for the American tactical market by Beyond and Outdoor Research, WL Gore has also launched the material in Asia for consumer products and Europe for the LE market. GORE-TEX Fabric with Stretch Technology is 25% more breathable than the membrane used in USSOCOM’s PCU Level 6 and reduces the accumulation of sweat thanks to the garment’s stretchable form fitting construction.

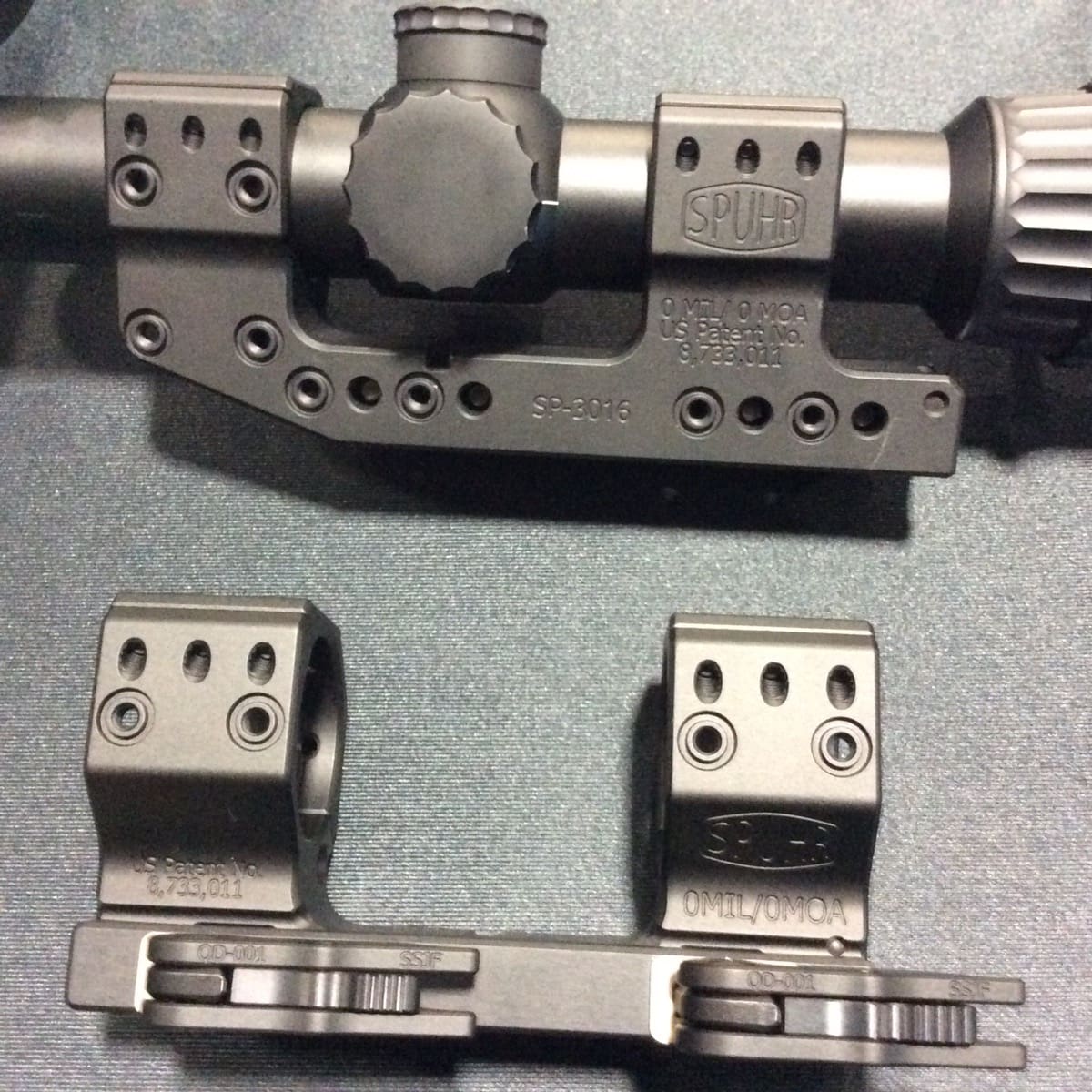

At SHOT Show, Spuhr exhibited pre-production versions of their new Quick Detach Picatinny series. The mounts have the same layout as their standard mounts. However, they’ve moved the side clamp from the right side to the left to avoid spent round ejection as well as any right side mounted controls.

In case you were wondering, this is the Spuhr QDP 4002 which offers 34mm tube compatibility and 1.5″ from centerline to top of Picatinny rail and no tilt. It’s shipping now, but additional models are coming.

One other difference is that they moved the logo on the QDP series in order to accommodate Spuhr interface holes for accessory mounting.

Spuhr AB products are available for unit and agency orders through Quantico Tactical.