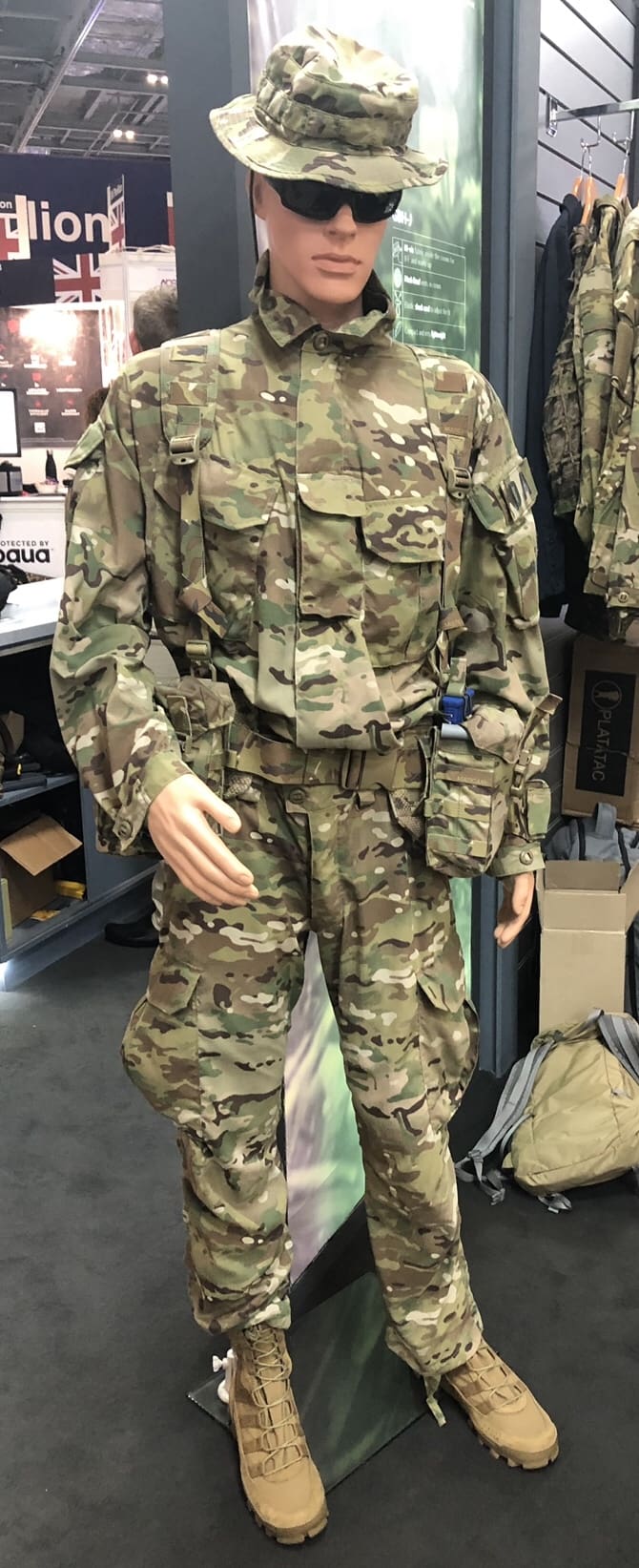

Platatac showed their Jungle Uniform consisting of GBH-J hat, Jungle “Kurtz” Shirt and Jungle Dax Pants, all manufactures from lightweight Apocalypse fabric in the MultiCam print.

The Hat features mesh panels. The Shirt incorporates five pockets with lanyard points, including a compass pocket at the chest. The Pants have a drawstring waist, and mesh lined large hip pockets.

Interestingly, the display also included the new Danner Jungle Boot, recently selected by the US Marine Corps. In addition to the rough out leather and nylon uppers, these unlined. Boots incorporate a Panama-style sole.