Yesterday, the US Army’s Program Executive Officer Soldier, responsible for the development, procurement, and lifecycle management of weapons and equipment used by the individual Soldier, hosted a media round table to update us on the Jungle Combat Boot (ver 2) and Improved Hot Weather Combat Uniform. These two pieces of vital clothing are intended for use in a hot, wet environment.

Providing the update was COL Stephen Thomas, Product Manager, Soldier Protection and Individual Equipment; LTC Jonathan Allen, Product Manager Soldier Clothing and Individual Equipment; and CPT Dan Ferenczy SCIE Assistant Product Manager, Environmental Clothing and Footwear. Both COL Thomas and LTC Allen came on board over the Summer while CPT Ferenczy has been working on this project for about a year.

COL Thomas kicked off the event with a brief overview of PM SPIE. He was followed by LTC Allen who brings a lot of energy to PM SCIE, which he refers to as the “Varsity Team” of PEO Soldier. He wanted to thank everyone who got them to where they are today in this project, Army and industry alike.

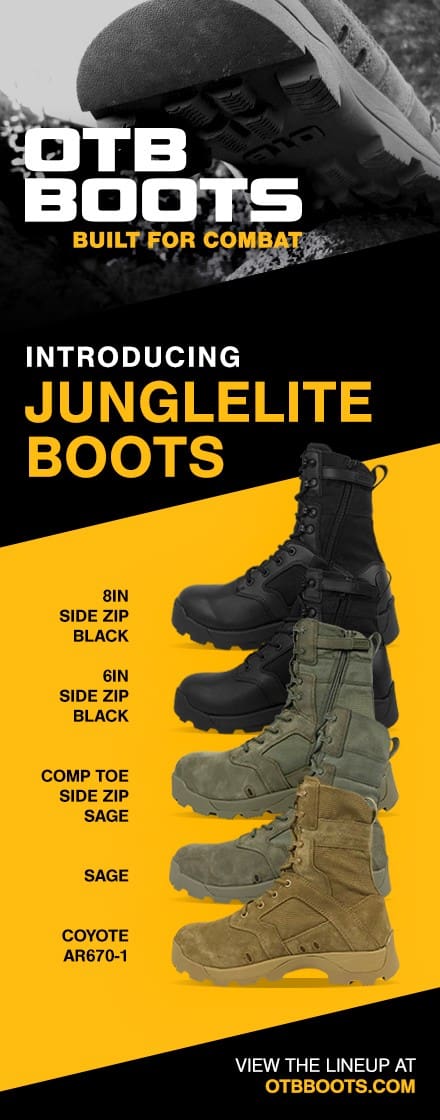

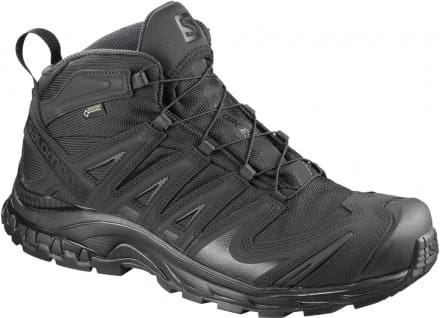

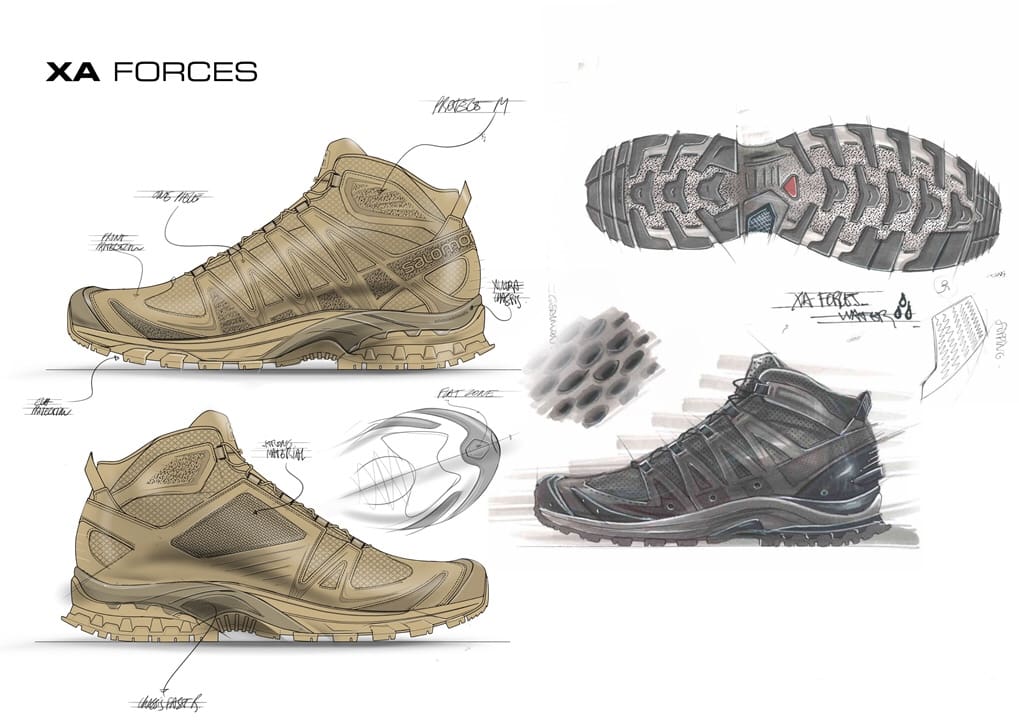

Jungle Combat Boot

Current issue boots are less than optimal for wear in the jungle. They lack puncture protection and feature additional layers for comfort which retain moisture. Initially, the Army evaluated Commercially available boots but found that they didn’t dry quickly and lacked drainage and traction in mud and didn’t shed excess mud.

Intended for use in a tropical, or hot wet environment, the Jungle Combat Boot has been a fast tracked acquisition. Within six months of the directed requirement being issued, the Army had taken delivery of the initial generation of boots and was fielding them to two Brigade Combat Teams in the 25th Infantry Division.

Fielding of an initial capability was so fast because readiness is the Army’s number one priority. However, the PM SCIE team has relied heavily on Soldier feedback to refine the requirement. For example, Soldiers want a boot that is more flexible, lighter weight and has a less thick sole than those initially fielded. The version 2 JCBs will also dry an hour faster than currently issued boots and feature a puncture resistant sole incorporating material which resists 200 lbs sq in of force. This will not only protect from thorns but also man made threats such as the “punji stakes” used in Vietnam.

PM SCIE is currently working with industry to conduct a wear test of a Gen 2 boot incorporating changes in 2nd Quarter FY18. In alphabetical order, the vendors are Altama, Bates, Belleville, McRae and Rocky. Based on feedback next March, PM SCIE will combine the best attributes into a common requirement. However, boots will continue to be refined until Soldiers are satisfied.

When asked if the Army had been working with SOCOM and the Marine Corps, both of whom also have Jungle Boot requirements, LTC Allen answered that they had. He related that the Army, Marine Corps and SOCOM teams work regularly together, sharing information. But, while the overall objective is a common boot for all services there are different requirements. For example, Marines prefer a 6-8″ tall boot, whereas Soldiers desire a taller boot.

Improved Hot Weather Combat Uniform

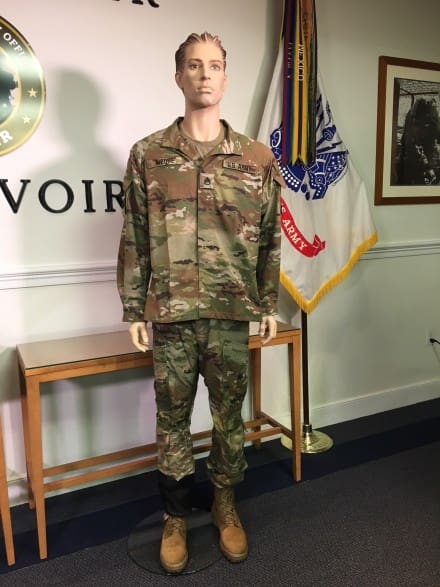

The IHWCU is intended as an alternative for the Army Combat Uniform for wesr in jungle environments. While the two uniforms share the Army’s Operational Camouflage Pattern, the design and fabric are both different.

The overall layout of the uniform is the most obvious difference. CPT Ferenczy said that they had also incorporated a quick dry fabric and long with general performance improvements. Overall, there are fewer layers and seams.

Jacket Improvements

No mandarin collar

Old style shoulder pockets with buttons

No breast pockets

Trouser Improvements

No rear pockets

Gussetted crotch

Articulated knee

Mesh ankle wrap

Aside from the fabric improvement, there are five major features on this uniform I’d like to point out. First, the lack of both chest and rear pockets. Second, the return to a more traditional, vertically oriented, button flapped shoulder pocket. Third, the reverse rake on the trouser cargo pockets, with the front of the pocket and flap being higher than the rear. Fourth, the introduction of a gusseted or diamond crutch for increased mobility and to reduce blowouts. Finally, the incorporation of the mesh ankle wrap. This feature has been quite popular and works like a gaiter to protect the Soldier’s legs from bugs and other pests when the trousers aren’t bloused due to heat and drainage concerns.

While the goal has been to reduce the amount of fabric on the garment, I’m surprised they’ve retained the lower leg pockets which don’t seem to offer much capability considering they will constantly catch on vegetation and fill with water. I’m also curious if any of these features will find their way over to the ACU.

Fabric

The current fabric being used for the IHWCU is a 5.7 oz, 57/43 NYCO blend by Invista. According to CPT Ferenczi, this new fabric also offers improved air permeability (breathability) of 70cfm versus the 30cfm of the ACU’s 50/50 NYCO. Thanks to the new fabric and design, the IHWCU boasts a 30 min faster dry time over the current 90 minutes for the ACU.

However, the Army is preparing to conduct a lab test of new hot weather fabrics and based on what they find, they plan to conduct an additional wear test of promising fabrics later this year.

When You’ll See Them

According to LTC Allen, 65,000 sets of the IHWCU are currently in production. In January, they plan to issue four uniforms and one pair of boots each to soldiers in one Hawaii-based battalion of the 25th ID.

Unless you’re in one of the test units at the 25th ID, there’s no word yet in when you’ll be issued the IHWCU and JCBs. The Army is still at least a year out from a final decision and hasn’t decided if these will become Clothing Bag items, common to all Soldiers or issued at CIF as Organizational Clothing and Individual Equipment.

PEO Soldier photos by Ronald T Lee.