?

?

MARINE CORPS BASE QUANTICO, Va. —

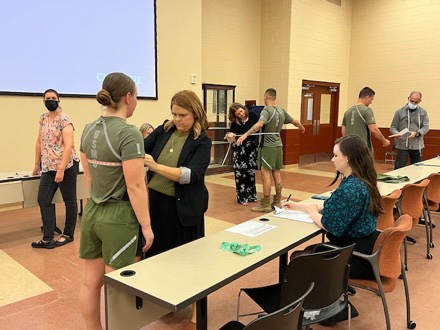

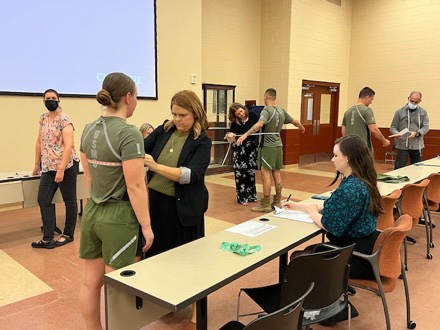

Last year, Marine Corps Systems Command received a requirement from the Marine Corps Uniform Board to redesign – and ultimately modernize – the Corps’ green-on-green physical training uniforms by incorporating industry trends to achieve better form, fit and function.

Although the initial prototype incorporated many innovations like anti-microbial technology, moisture-wicking, fast-drying fabrics and reflective elements, many Marines were unsatisfied with the new design and asked for some changes.

After last year’s successful limited user evaluation, MCSC’s Product Manager Clothing and Equipment team is back with a new and improved PT uniform prototype.

While the beloved “silkies” unfortunately will not be making a comeback, Kristine Bealmear, the PT uniform project officer with MCSC’s clothing and equipment team, feels confident that Marines will like the revised uniforms.

“I think they’re going to like them a lot better than the previous prototypes. I think the women are going to be a lot happier,” she said with a smile.

After all, it was the input of approximately 350 leathernecks that drove this round’s creative process.

“The results from last year’s [limited user evaluation] were clear. The material was heavy. The shorts were long. The reflective material was restrictive. And so, we just kind of took all of that information and we went from there,” Bealmear explained. “The Marines are the ones that have to wear this uniform so it’s in our best interest to listen to what they have to say.”

Now, the PT uniform’s shorts are shorter and down to a 5-inch inseam. The PT uniform’s shirt material is lighter and the reflective striping down the back is thinner – a change that will allow Marines to remain cool and flexible as they exercise.

“If you look at the new PT uniform, it does have a shorter inseam, which is more in line with what we see in industry. Industry trends come and go, so we look at every design detail individually and decide what we should apply today that could still be relevant to the Corps years from now,” said Emily Madden, a clothing designer supporting MCSC from the U.S. Army Combat Capabilities Development Command Soldier Center.

One of the most exciting changes, however, is the shift away from gender-neutral sizing.

“We found that gender-neutral sizing does not work well for our women Marines,” Bealmear explained. “With the last prototype, for example, we found that if the shirt fit them well across the bust line, it was too big in the neck. Same with the shorts – if they fit in the waist, they were probably tight across the hip line.”

“And so, we took all of that test data, a lot of pictures, a lot of feedback, and we made the necessary changes. Gender neutrality in design is a thing of the past.”

“I think it’s really important to make sure that all Marines have the proper fitting uniform for what their mission may require, in regards to fit, form and function,” Madden added.

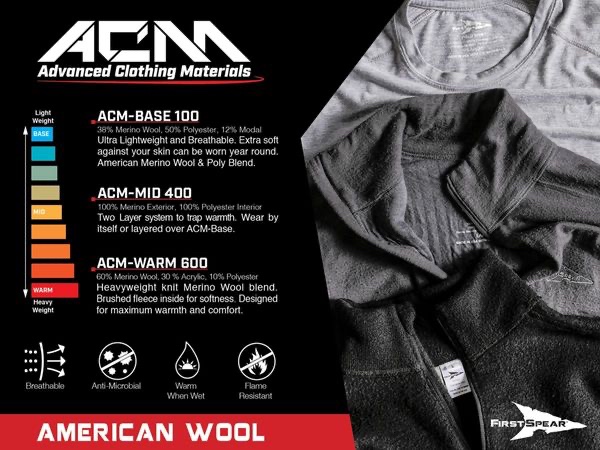

But the design team was driven by more than just user feedback; they were also guided by industry best practices with innovation in fabric and design.

“We really leaned on industry to better understand manufacturing techniques and design details at a reasonable price point, but we also worked closely with our service partners from the Air Force, Space Force and Navy to better understand fabrics and material weights,” Madden explained. “Ultimately, we tried to leverage industry while still accommodating what a Marine could need or want.”

The new PT uniform isn’t ready for distribution across the Corps quite yet, though. MCSC’s clothing and equipment team is in the midst of conducting another user evaluation to solicit Marines’ feedback on the redesigned uniform. During the current evaluation, which started in September and runs for 30 days through October, the team issued PT uniforms to approximately 350 Marines, who were asked to wear and evaluate the new uniforms while they PT.

Afterward, the team will survey all evaluation participants in order to collect data related to the uniform’s form, fit, function and comfort. Participants will also take part in group discussions about their wear experience.

Ultimately, the team will take the results of the survey, group discussions and the initial fit assessment to determine any necessary changes to the redesigned PT uniform prototype. This rigorous process ensures the product is ready for use by Marines across the country.

“I ask them to ‘use it and abuse it,’ as I like to say, because we really need that durability feedback from them,” Bealmear explained. “After the 30-day trial is done, we’ll go on to evaluating the results and make the necessary changes.”

“We think the new PT uniform accommodates fit, form and function of both male and female Marines. There will always be tweaks that we can find or improve upon, but we think we’re headed in the right direction,” she added.

Johannes Schmidt, MCSC Office Public Affairs and Communication

Photos by Ashley Calingo, Tonya Smith and Johannes Schmidt

?

?