SSD has written about the Army’s Fire Resistant Environmental Ensemble in the past and our only criticism is the basis of issue. Designed specifically for Aircrew and Mounted Crewmen, FREE is a skin-out FR environmental clothing system that protects down to -40 deg F. Unfortunately, FREE is not issued to dismounted troops. However, they do get the Extreme Cold Weather Clothing System Gen III which is a great clothing system but it’s not FR. The problem is that the dismounts ride around in aircraft, trucks and armored vehicles getting from point A to B and are just as much at risk of IED and other flame threats as the troops who are issued FREE. And that’s not to mention the risks of dismounted patrolling and attacks on FOBs.

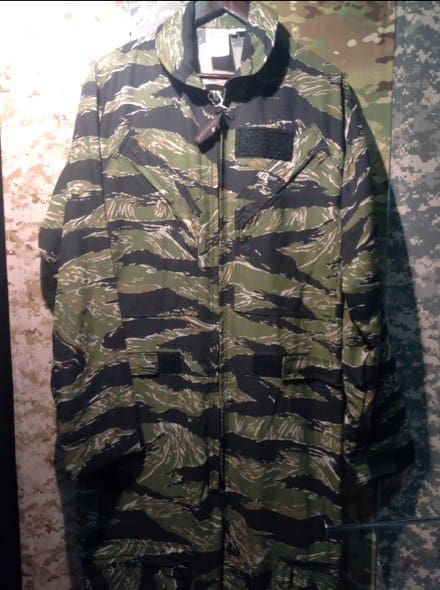

If you are already using ECWCS Gen III then Dismounted FREE will be very familiar to you. It has been optimized for ground operations and consists of Light-Weight Undershirt and Drawers, Mid-Weight Shirt and Drawers, High-Loft Fleece Jacket, Soft Shell Jacket and Trousers, Extreme Cold/Wet Weather Jacket and Trousers. And, like Gen III it is available in Top and Bottom kits in addition to two optional items not included in either kit; the Parka and Overtrouser. As you can see, it is a very streamlined kit and sticks with FR versions of the most commonly used garments.

Additionally, unlike ECWCS Gen III, Dismounted FREE is designed to integrate the FR ACU, Army Combat Shirt, or other FR level 9 garments into the system. Considering that the Soldier is always going to be wearing a combat uniform, it only makes sense that the environmental layers integrate with it.

Dismounted FREE From ADS Inc

Dismounted FREE is available in UCP or OCP camo patterns in sizes XS – XXL in short, regular, and long lengths. All of the clothing in the kit is Berry compliant and FR. Dismounted FREE drastically increases the protection of the ground Soldier and offers a cost effective alternative to issuing FREE to everyone. It’s important to note that this is not an Army program and that ADS developed Dismounted FREE internally as a solution for the Soldier protection issues we identified above. We are impressed with what we see and hope that the military takes a serious look at this option which leverages proven technologies and is available now as a Commercial-Off-The-Shelf solution.

www.adsinc.com