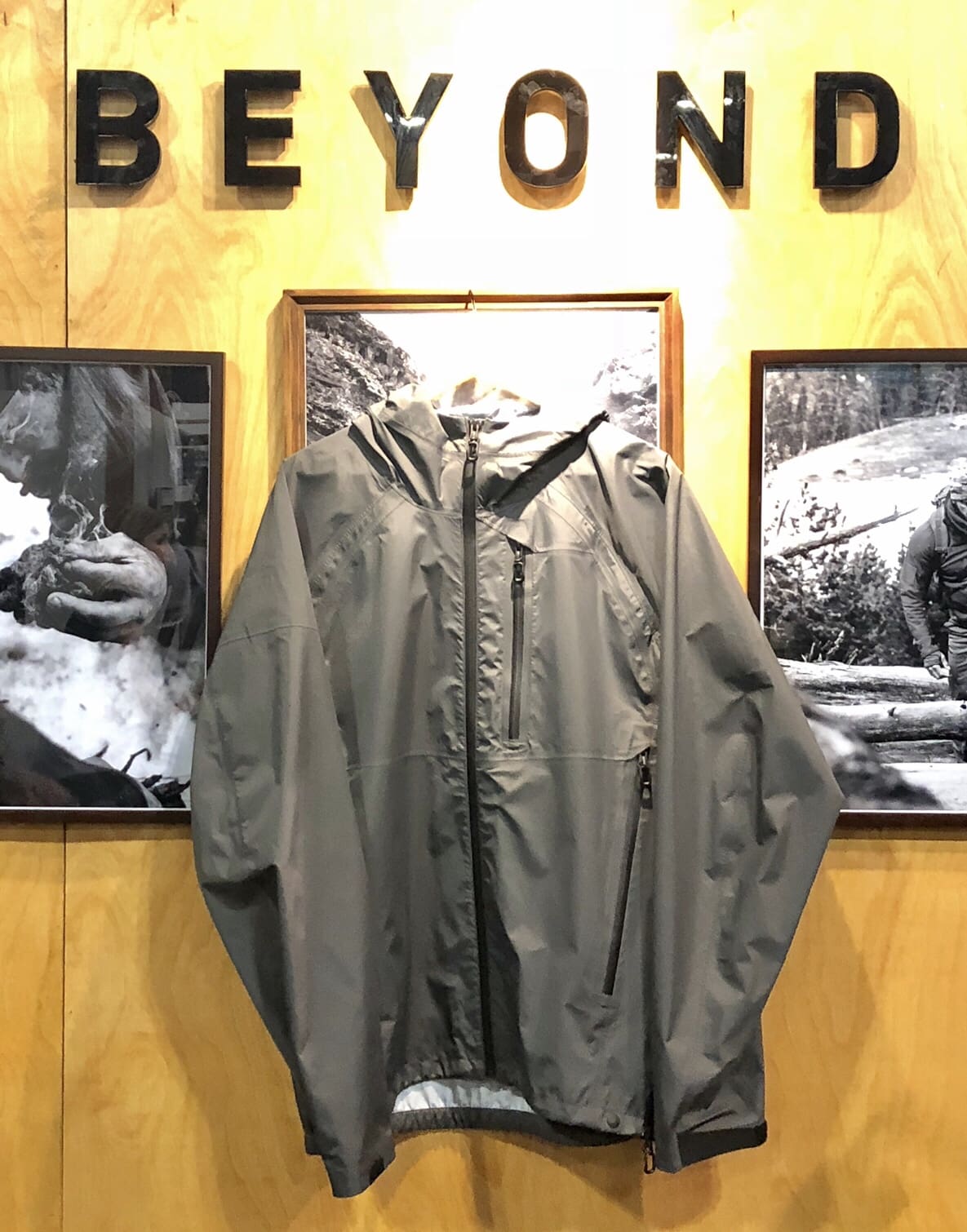

In this exclusive interview, we spoke with Kavan Cronin, a Color Designer for Arc’teryx LEAF, and the man behind the Wolf Urban Grey color.

SSD: Who are you & what is your role at Arc’teryx?

KC: My name is Kavan, I am a Colour Designer at Arc’teryx and have been working in this department for 10 years.”

SSD: So you’ll have seen a lot of colours come and go in those years. Tell us why Arc’teryx has a specific Color Design Department, because this isn’t normal in the industry, correct?

KC: No it’s unusual. It’s a big point of difference for the brand. Our team is dedicated to colouring all of Arc’teryx products including LEAF, and we maintain a strong level of control right down to the minutest details.

Our team is split between colour designers, colour administration and quality control. The colour administrators interface with our material vendors, and control the sending and receiving of lab dips. They also maintain our extensive library of colour standards & lab dips, our sample yardage room, as well as many of the tools the colour designers use regularly.

Every uniquely coloured fabric passes through the hands of our colour quality control specialist. They are in charge of measuring all lab dips and sample yardage cuttings and maintenance of the measurement database. They helps to identifying trends in how colours are shifting from standards during the lab dipping process, and how different materials absorb dye. The designers work closely with them to make informed decisions.

As colour designers, we are behind the actual colouring of the products. We work closely with our product designers to capture their vision and intentions while we’re going through our colour palette development process, to ensure we are aligned with a strong story to convey. We also incorporate the expertise of our product line managers to make sure end use needs of each product are met, and that the message behind each collection is cohesive and impactful.

Our approach to inspiration, and how it is distilled and translated into a colour palette has continued to evolve over the years. Recently we’ve been looking at global trends and macro trends that we find inspiring or impactful, reviewing them as a group, and selecting the ones we feel are the strongest inspirational stories for each season. They can be rooted in anything from nature, technology to graffiti art!”

SSD: How does the department work with the LEAF line, not too many color differentials there!

KC: You be surprised. LEAF may seem on the surface to have a very obvious colour palate, but there is a story behind each of them! LEAF colour needs are very specific, they are typically defined by ongoing communication between the LEAF development team and our established network of end users and their requirements.

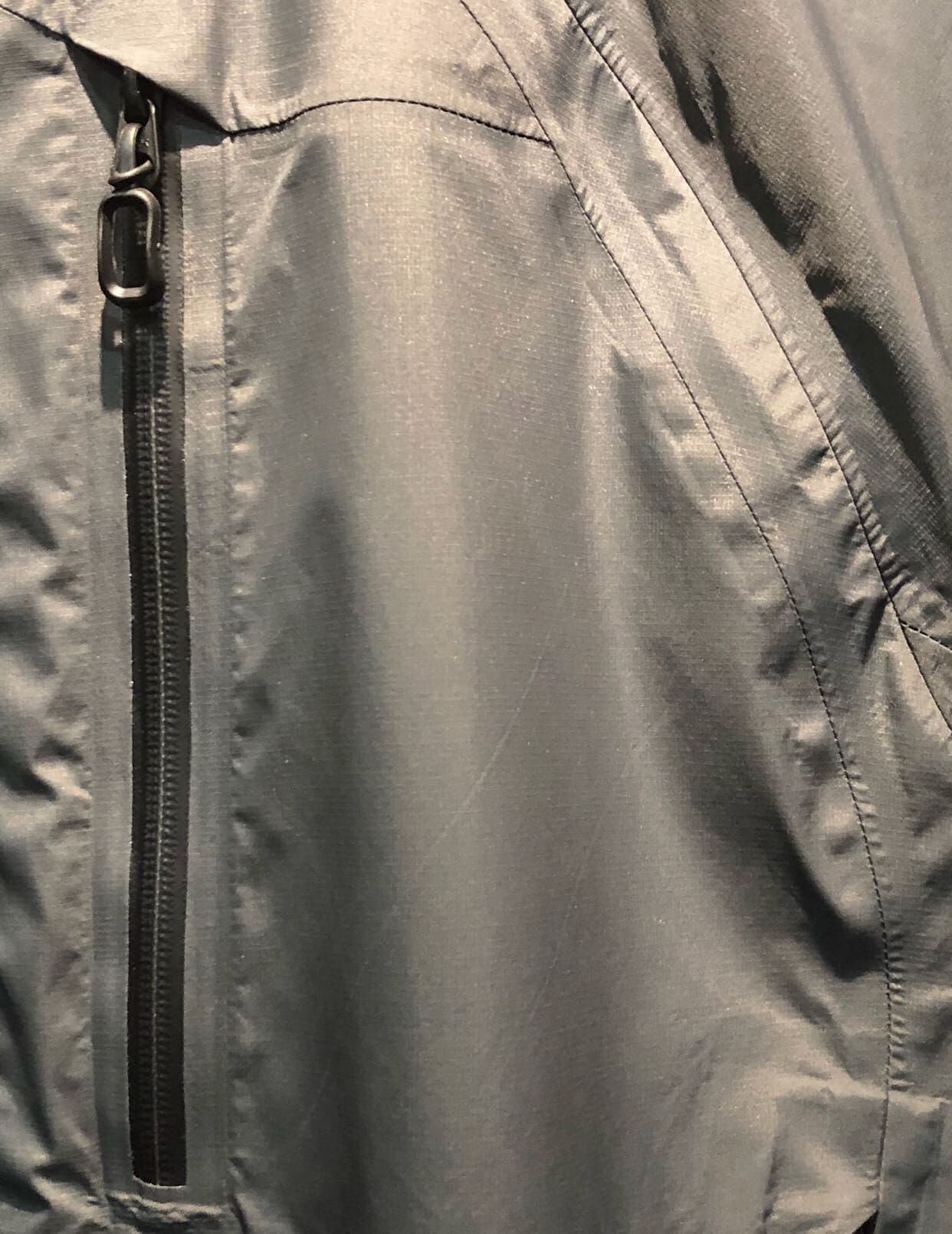

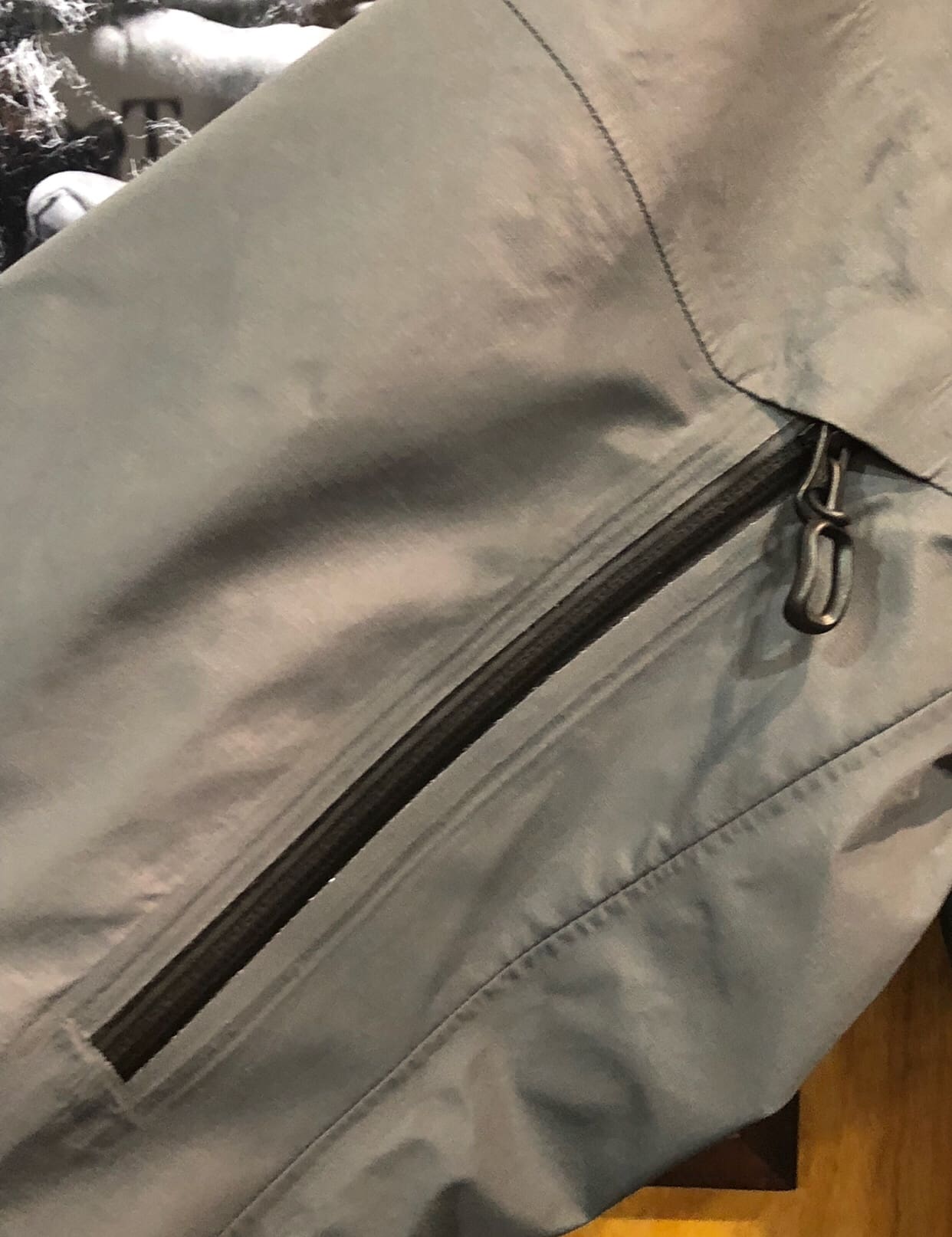

Wolf has an interesting background. The brief that I was originally given, touched on external studies stating that that a dark neutral grey was more likely to blend easily into its background under low light conditions than black. The idea was to use this knowledge to identify the ideal grey to be applied to a new uniform program for specialized LE teams. However, as these uniforms were not always going to be used in the dark, we didn’t want the uniforms to be too dark of a grey. They needed to blend into the urban environment under differing light conditions. Taking all of this into consideration, I spent some time doing personal exploration around the city (Vancouver) observing the various shades of grey as seen from roads, buildings, cement barriers, etc. As well as reviewing countless images from other major cities across the world. I was able to narrow down to 4 shades, which we reviewed as a group to zero in on the best option. This was the birth of (Urban) Wolf. Wolf then became widely adopted in the industry, it was an exciting colour evolution to be a part of. ”

SSD: Croc is another colour synonymous with the LEAF line – but what is the history behind this colour way?

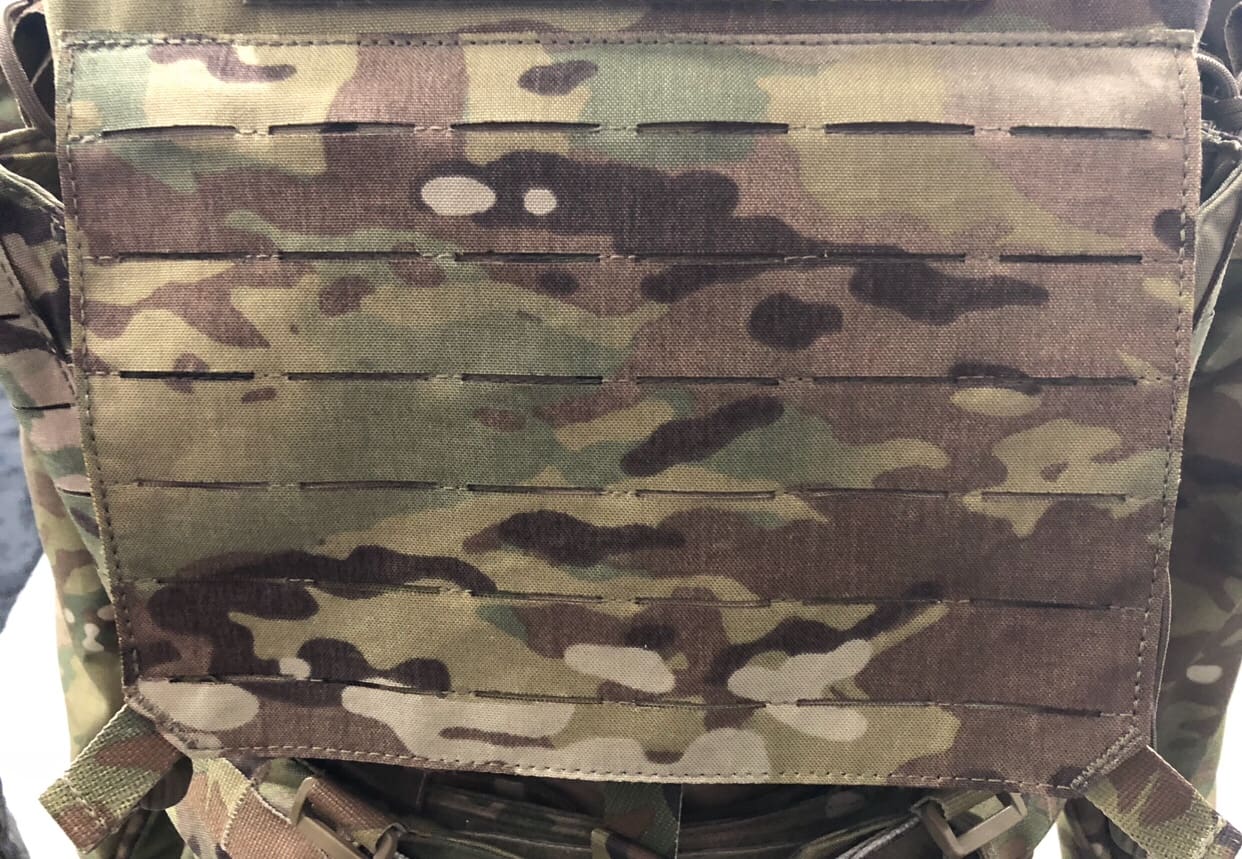

KC: Crocodile was born of a time when camo patterns were the norm, but no one pattern would fit the global market. Multicam barely existed and there was much discussion around its use vs. the traditional US ARMY UCP. Not to mention, due to the fact that all camo patterns are licenced, and require third party printing, material cost was much higher than if a solid colour was used. Picking a solid colour for our LEAF apparel was the best option, the caveat being it had to be universally adaptable.

Crocodile was based off the Canadian military’s version of OD Green, which had just been phased out in favour of CADPAT. OD Green was a very adaptable colour, but was a little bit too green. The colour standard selected for Crocodile had a bit more brown in it, and it was better suited to woodland and mixed environments. Ranger Green did exist at the time, but was deemed too black.

There were discussions about changing to another colour over the years, but what colour..? The market was fragmented on what they wanted/needed, and Crocodile just kept getting the job done. Due to its adaptability, Crocodile grew and became the staple in the Arc’teryx LEAF line. Despite the introduction of Wolf, and then Ranger Green, Crocodile continues to be “the” colour synonymous with Arc’teryx LEAF.

SSD: Do you see any future color changes in the market?

KC: 2018 we introduced Harrier Grey in our new Cold Weather SVX Parka & Bibs. Intended for extreme cold weather use, people have asked us why we didn’t make them in white. Simple answer, white doesn’t stay white for long! Harrier Grey is a perfect gery to be under over whites, and allows our end users more versatility of environmental usage than just white would.

To learn more about Kavan and what he does, check out this profile video, part of Arc’teryx’s “Who We Are” video series.