This is a great piece of news. The Product Manager for Soldier Clothing and Individual Equipment (PdM SCIE) has identified a need for a new modular and tailorable holster system in support of the Product Manager for Individual Weapons (PdM IW) Modular Handgun System (MHS) XM17 program.

While the pistol is PdM IW’s bailiwick, it’s PdM SCIE’s responsibility to maintain, develop, and improve Soldier clothing and individual equipment to include holsters as the life cycle manager of these items. They’ve fielded holsters in the past. For example, in 2013 they began fielding the Blackhawk SERPA and a G-Code holster for the M9 Handgun.

However, along with the pistol it will support, this requirement is new and has us excited. To begin with, it shows that the XM17 is alive and kicking and far enough along to give accessories like holsters a serious look. What’s more, it’s good to see PdM SPIE working with PdM IW to field a holistic solution which crosses commodities between the two teams. The XM17 solicitation did call for holsters, but as we’ll show below, the holster concepts weren’t nearly as ambitious as the requirement for the pistol.

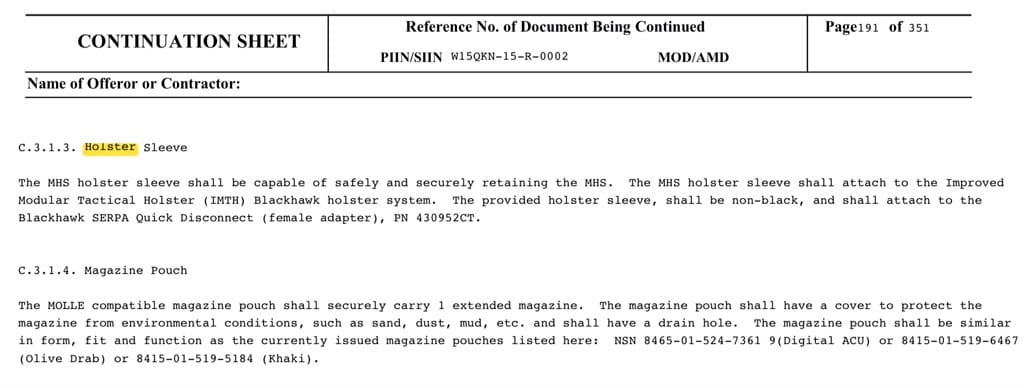

In the solicitation for the Modular Handgun System, the offerer’s were required to provide Holster Sleeves to fit the Blackhawk SERPA Improved Modular Tactical Holster.

The offerors were also required to provide compact holsters, which were essential Safariland ALS holsters.

In both cases, the holsters are well established legacy systems, in wide use. Whether you like them or not, they are industry standard holsters. But if the Army is to get a new pistol, why not see what industry is capable of and field a new holster as well?

That’s the point of this call to industry requesting formation on what they are capable of regarding holsters. Specifically, they are asking a lot and hopedully, industry will step up to the plate. Here is a sampling of what they are seeking; the entire list can be found at www.fbo.gov.

Key Performance Parameters

KPP 1 – Interoperability

The AMTH will carry a M17 pistol (T) and will be interoperable with any other MHS variants (i.e. Compact, etc.) (T). The AMTH must accept the M17 with suppressor kit, without actual suppressor in place (T), or with suppressor in place (O).The AMTH will accommodate future handguns used by Soldiers by providing an interchangeable holster sleeve variant (T), with one holster system (O).

Rationale: Compact variant users may need to carry their handguns in an overt/tactical method in the course of their duties and it would be necessary for the full size holster to accommodate the compact variant. In the event a new handgun is needed, the existing holster will need to holster or adapt to holster the new weapon to ensure Soldiers have a holster system available for use. The MHS suppressor kit may include a longer threaded barrel and higher than normal sights. The holster must accept the weapon configured for suppressed use, while accepting a fully suppressed MHS is an objective. Other methods of carrying fully suppressed pistols exist that may be more operationally suitable to the user.

KPP 2 – Modularity of Mounting Positions

The AMTH must be modular and provide three (3) mounting options, 1) mounting on equipment using standard Pouch Attachment Ladder System (PALS) webbing; 2) on a belt; 3) and a drop leg configuration (T=O). In any of the configurations the MHS Tactical Holster must be adjustable to accommodate a vertical or cross drawing of the handgun (T=O).

Rationale: The MHS must have a holster associated that allows the user to wear the system securely on their person and allows them to do all combat/battlefield required tasks. Users have a need for a holster to allow them to securely carry and quickly employ the MHS. Users currently have the modular capability to transfer the holster from chest (MOLLE) to hip to thigh carry in seconds without removing the weapon from the holster sleeve. Users require this capability in the AMTH, for example, when transitioning from riding in a vehicle to dismount and individual movement to key leader engagement. Users of the MHS will need to use one or both hands to conduct battlefield tasks while still maintaining a tactical advantage. Therefore, Users of the MHS will need to have the ability to draw the weapon effectively with one hand quickly and efficiently.

KPP 3 – Retention

The AMTH must provide retention upon holstering without the activation or manipulation of first level retention devices to secure the handgun when Soldiers are training and conducting combat operations (T). The AMTH will have to carry the pistol in a manner that conforms to the shape of the handgun and ensure the handgun is securely held within the holster (T). The AMTH must provide redundant systems to ensure the handgun is secure (O) and prevents someone other than the Soldier from drawing the handgun (O). The AMTH must provide one level of retention (T), two levels of retention (O). No retention buttons, switches, levers, etc. will use the Soldier’s trigger finger to release the handgun (T=O). None of the retention systems will cause damage to the pistol (T=O).

Rationale: Soldiers require the ability to draw handguns from holsters and re-holster with one hand reliably when transitioning from another weapon system, or when presented with a lethal force engagement with little or no warning when only armed with a handgun. This requires that Soldiers be capable of drawing the weapon quickly with one fluid motion, attain a proper firing grip from the holster, engage enemy targets, holster the weapon and potentially repeat the process during the same engagement or in successive engagements. Through all of this, Soldiers require the ability to continue to conduct other tasks with the non-dominant/non-firing hand and maintain situational awareness of their battle space. Therefore, Soldiers must be able to conduct draw and re-holster with one hand and without looking or glancing away from their near-target environment.

KPP 4 – Ergonomics

AMTH must be manufactured in variants for right and left hand dominant personnel (T) or have one variant which allows for ambidextrous access of the weapon without an increase to the size of the holster (O). The AMTH must allow the Soldier to draw and re-holster the weapon continually with one hand (T=O).

Rationale: Users need to be capable of carrying/accessing the holster on the dominant side. Objective ambidexterity in the holster permits logistical streamlining, but not at the expense of ergonomics or increased bulk/snagging hazard. Many users of the MHS need to use one or both hands while maintaining a tactical advantage. Being able to draw and re-holster with one hand and without taking eyes off the target area allows the user to maintain situational awareness and tactical advantage.

Key System Attributes

KSA 1 – Construction Materials

The AMTH must be constructed of materials that are non-magnetic, non-corrosive, block absorption of blood-borne pathogens or other biological fluids, fungus resistant and fire resistant (T=O). The AMTH shall not be degraded by CBRN decontamination materials; insect repellant; sea water; and commonly used petroleum, oil, and lubricants (POL) (T=O). The materials of the AMTH that contact the handgun will not mar the manufacturer-applied finish of the weapon (T). The color of the AMTH will be Tan 499 (T), Operational Camouflage Pattern (O). The external surfaces of the AMTH must be dull, non-reflective, and must not contribute to visual (T) or infrared signatures (O). The AMTH must not have visible logos or distinctive commercial markings when worn by the Soldier (T=O).

Rationale: The holster is not considered CBRN mission critical but is a durable item, as such, it needs to be capable of surviving CBRN training regimen and commonly used POL and insect repellants. The weapon finish prevents corrosion and maintains a level of operational security through camouflage. It is expected and acceptable that the holster may affect user-applied paints and camouflage that are less resilient than the factory-applied finish. The holster should not damage the finish and induce increased maintenance or corrosion of the weapon. Tan 499 is an approved Tank and Automotive Command (TACOM) color via Memorandum for Program Manger Soldier Weapons, Small Arms Weapons Neutral (Non-Black) Color, dated 31 January 2014.

KSA 2 – Configuration/Reconfiguration

Initial configuration and adjustment of the mounting system for the AMTH will be conducted at the operator level and will be accomplished without the use of special tools (T=O). Once set to the Soldier’s preferences, the AMTH must allow for placement between any of the three modular mounting systems without the need for tools in no more than 20 seconds (T=O).

Rationale: Initial configuration and/or reconfiguration is a task that would be conducted in a maintenance-type environment and not under fire. Soldiers do not have access to special tools and introducing special tools is not desired. The Soldier does have a common tool (multi-tool) that has narrow and wide blade flat screw driver tips and a #2 Phillips screw driver tip. Transition from one modular placement platform to another needs to be conducted in a combat environment (e.g., exiting or entering vehicles, drop zones or landing zones, etc.) and the Soldier should be able to do so without the use of tools in an expeditious manner.

KSA 3 – Airborne/Air Assault

The AMTH will include a retention system that can be configured in preparation of operations such as military free fall, static line parachute, air assault/fast roping, SPIES/FRIES, combat diver, patrol boat operations, hovercraft operations, rappelling, mountaineering, jungle penetrations, All Terrain Vehicle Operations, swimming, etc. which is installed before the operation and removed when extra retention is no longer required (T); is part of the holsters retention system (O). When conducting these dynamic movements, the Soldier will require multiple steps to draw the handgun (e.g., installing and removing bungee straps, manipulating locking levers, etc.) (T), be able to draw and holster the handgun continually with one hand (e.g., having additional steps with collocated levers, etc.) (O).

Rationale: Soldiers occasionally are required to conduct highly dynamic mission-critical tasks that may exceed the limitations of standard holster retention devices. If the standard retention device is not sufficiently robust to maintain security of the weapon, another form of retention is needed to ensure the weapon is secure. These operations are pre-planned thoroughly and configuration would not be necessary on short order or under fire. The need to present the weapon for use during these situations is real; therefore, Soldiers would still need to be able to do so in a timely manner and potentially with only the firing hand, and then re-holster and secure the weapon to continue the dynamic event.

KSA 4 – Law Enforcement Configuration

The AMTH must provide a Law Enforcement configuration (T). The AMTH Law Enforcement configuration will have additional mounting platforms and/or parts that can be added to the AMTH to meet the Law Enforcement Configuration or be a variant that attaches to the AMTH platforms (T), be the same as the AMTH with no additional parts (O). The Law Enforcement configuration will consist of a holster sleeve and a mounting system that is compatible with existing Military Police Law Enforcement Ensemble Kit (LEEK) belt dimensions (T). All components of the Law Enforcement Configuration will be black in color (T=O). The Law Enforcement Configuration will have a mounting platform that is user adjustable for height, adjustable to below/above the belt wear, and capable of being angled to slant holster away from the user’s hips (T) by providing an additional belt mounting system to the AMTH that provides the required adjustability (O).

Rationale: Military Police conducting Law Enforcement Operations have special capability needs. It is logistically prudent to ensure the Law Enforcement configuration is compatible with the AMTH. LEEK belt and accessory dimensions and characteristics will need to be compatible with AMTH LE configurations.

KSA 5 – Target Acquisition

The AMTH must have a variant capable of holstering the XM17 with target acquisition enablers (lights, lasers, pointers) mounted on the forward rail of the handgun, which does not extend forward of the muzzle or below the lowest portion of the trigger guard, and is not more than 1.5 inches wide (T). The AMTH must be capable of holstering the XM17 with target acquisition enablers (lights, lasers, pointers) mounted on the forward rail of the handgun, which does not extend forward of the muzzle or below the lowest portion of the trigger guard, and is not more than 1.5 inches wide (O). The AMTH must be capable of holstering the XM17 with target engagement enabler (mini red dot sight, RMR, etc.) mounted on the top of the handgun slide (O).

Rationale: Soldiers that require target acquisition enablers need to be capable of employing those enablers straight from the holster. When using night optical devices, it is imperative that the weapon be equipped with target acquisition enablers to be able to engage threats with any degree of accuracy. Installing the enabler after drawing the handgun and then removing the enabler prior to re-holstering is not acceptable in any situation. Installing the enabler on a loaded handgun while under fire is unsafe. Enabler fit is based on the required capabilities of the XM17 enabler SEP effort. Intent of the threshold is to have an AMTH variant for enabled pistols. Intent of the objective is to have a single AMTH that accepts both enabled and non-enabled pistols. It is possible that the XM17 will be capable of accepting mini red dot sights (MRDS). There are also other efforts that are reviewing the viability of MRDS for pistols. It is reasonable and prudent to expect some users will have a need to holster the XM17 with MRDS capabilities mounted on the weapon.

KSA 6 – Cost

The Tactical Holster system with holster sleeve and three mounting positions will cost less than $100 (T), $70 (O). The Law Enforcement configuration will cost less than $50 (T), $20 (O) for the law enforcement adapter.

Interested parties have 45 days to submit in response to this Request for Information. Full details can be found at www.fbo.gov