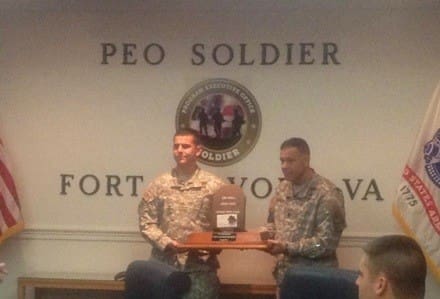

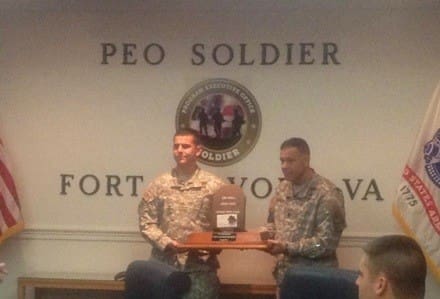

At 0912 hours on 12 August, 2012 while conducting a route clearance patrol near SP Panza, Afghanistan, SGT Joseph Morrissey of C Troop 4-73 Cavalry, 82nd Abn Div was shot in the chest by a 7.62 round from a distance of 30m. It hit right in his ESAPI plate which absorbed the blow and saved his life. Yesterday, that plate was returned by Program Executive Office Soldier’s SEA, CSM Maunakea.

Surprisingly, right after the incident, his unit initially thought they might have to MEDEVAC him due to the shot, but once they sat him down and conducted an assessment they realized that the projectile had not penetrated through his vest and all he needed to do was replace his front ESAPI plate. They did that and he was returned right back to his patrol.

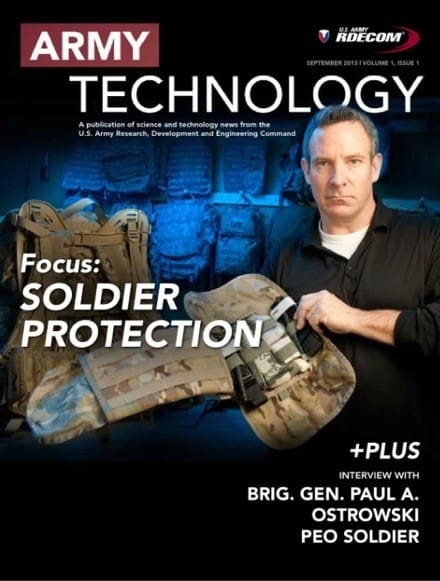

The plate was returned to SGT Morrissey courtesy of the Joint Trauma Analysis and Prevention of Injury in Combat Program at Ft Detrick which funds collection and analysis of PPE. Although it’s a joint program, the actual analysis is conducted by personnel from Program Executive Office Soldier to determine how well it performs against real threats and to use the information to make better armor systems in the future.

According to COL Marilyn Brew (USA) a PM at JTAPICP, the program has been around since 2006. She related that in addition to Armor Plates, they also analyze soft armor, helmets and other armor items, regardless of the service of origin. Amanda Perry of the Technical management directorate explained that they have over 70,000 data points in their database.

This was a great opportunity for SGT Morrissey to meet the men and women behind the equipment that saved his life. Conversely, the team at PEO Soldier had a chance to put a face on the work that they do.

SGT Morrissey took the opportunity to thank everyone at PEO Soldier. He explained that prior to the visit, he had no idea that a place like PEO Soldier even existed but said that he would spread the gospel once he returned to his unit at Ft Bragg.

When I asked him about his PPE his answer was simple, “It Works.” He went on to tell me that prior to this incident he was no fan of body armor, but now? “If it wasn’t for this equipment, I’d be dead.” And that pretty much sums it up, doesn’t it?

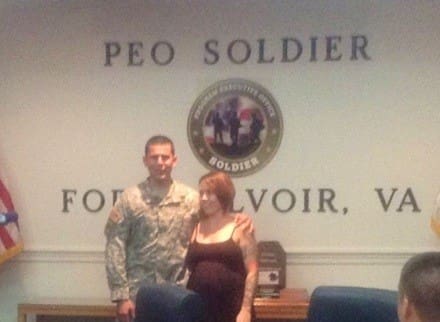

SGT Morrissey was accompanied to the ceremony by wife Nikki and battle buddy SPC Samuel Walley.

SSD wishes SGT Morrissey and his lovely wife well as they will soon become parents. We’d also like to thanks PEO Soldier for the opportunity to visit their facility and cover this story.