“Pew! Pew! Pew!”, everyone wants that. And like with techno music, everyone wants to know how fast the beat booms. “Beats per minute” is the correct term for that in music, “Rounds per minute” in the military. And that‘s exactly the name of the new App by TACTICALMEASUREMENTS: MyRPM. It will be released on the 31st of January and is available for Download on the Google Play Store. A version for iOS is already on the way. We from SPARTANAT have already been on a shooting range – and let our guns rattle.

That‘s the sound of music… To generate the tunes that are analyzed by MyRPM we have used two boom boxes: a M16 and a MP5. In the photo above you can see the magazine with 5.56 ammunition. The second magazine – not in the picture – is much slimmer and is filled with 9mm ammunition.

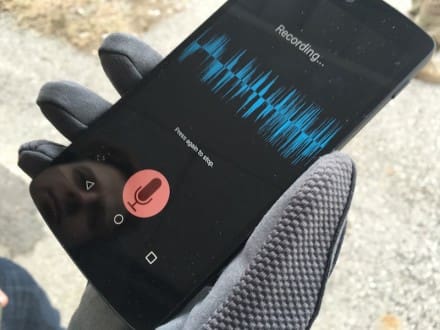

And that’s our measurement device. Up to now the measurement of the Rate Of Fire has been complicated and inconvenient with special hardware required – expensive and with varying accuracy. With MyRPM everything works on a smartphone. The App is activated by pressing a button. We will explain the rest to you in a jiffy – it pays off to watch the video. It shows how astonishingly simple it is to measure the Rate Of Fire.

…3, 2, 1 – record. Whilst getting you firearm in the shooting position, a countdown allows you to get ready for the measurement. MyRPM can be used in- & outdoors. Keep in mind that wind, voices and other shots should be avoided during a measurement.

Rock‘n‘Roll! – Like you can see in the video, this is the sound of a M16. When you are satisfied, just press Stop or use the automatic record timer. A few seconds are enough to achieve a result.

Now you can proceed to the analysis: First, the record taken by MyRPM is documented. The sequence is displayed in a graph and can be saved for further use.

But first of all the concrete result is of interest: 756 Rounds Per Minute are fired by this american boomstick.

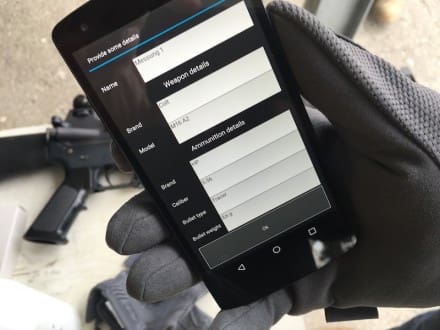

Data saved until infinity: The result can be saved effortlessly. That‘s interesting because it helps the user to check how different types of ammunition affect the Rate Of Fire of his gun. The powerful algorithm of MyRPM makes it possible…

That’s the result of the MP5 with the used ammunition next to it. Also taking this measurement was uncomplicated and fast, precise and effortless.

MyRPM is an affordable and reliable tool for gunsmiths, marksmen and everyone who wants to know more about their firearm. It shouldn’t be missing on any smartphone. It´s an affordable and reliable tool that allows you to analyze and control your weapon system. We are excited about what´s coming next from TACTICALMEASUREMENTS.

MyRPM is available on Android in two versions (iOS is coming soon):

– MyRPM – Limited functionality (save max. 3 results, contains ads). The free version gives everyone the possibility to try out the product.

– MyRPM Pro – Full functionality. The full version allows you to save as many results as you want and you are not getting bothered by ads. The full version is available for just $ 20.99.

MyRPM Pro

play.google.com/store/apps/details?id=com.tacticalmeasurements.myrpmpro

MyRPM

play.google.com/store/apps/details?id=com.tacticalmeasurements.myrpm

Instagram

www.instagram.com/tacticalmeasurements

YouTube

www.youtube.com/channel/UCMJMoJmIJzzt7lf3t0QA9vg

Facebook:

www.facebook.com/TACTICALMEASUREMENTS

Homepage:

tacticalmeasurements.com

Article by SPARTANAT: spartanat.com