QUANTICO, Va. —

As recent developments in distant battlefields have shown, successful military operations rely on resilient communication architectures capable of closing kill chains in austere environments.

In order to maintain fleet lethality, Marine Corps Systems Command is working on fielding a state-of-the-art multichannel handheld radio system that mitigates against peer adversary threats and enables Marines to quickly add new waveforms and enhanced capabilities to address evolving requirements.

“The Multichannel radio family of systems will provide the [Fleet Marine Force] with an enhanced capability that increases resiliency and survivability through network interoperability during missions involving both ground and vehicular-based forces,” said Richard Sessions, program manager for communications systems at MARCORSYSCOM. “These new radios will provide the fleet with many new options in configuring communications and network pathways while leveraging newer, more secure waveforms.”

Ultimately, this effort will help further the Department of Defense’s 2022 National Defense Strategy, which calls for preserving command, control, and communications in a fast-paced battlefield. Furthermore, it falls in line with the Department’s Joint All-Domain Command and Control Implementation Plan – or JADC2—a “warfighting necessity to keep pace with the volume and complexity of data in modern warfare and to defeat adversaries decisively.”

“What I really appreciate about the team is their investment. It’s something I see from government, civilians, and contractors alike…”

Lt. Col. Joshua Kapp, product manager for ground radios

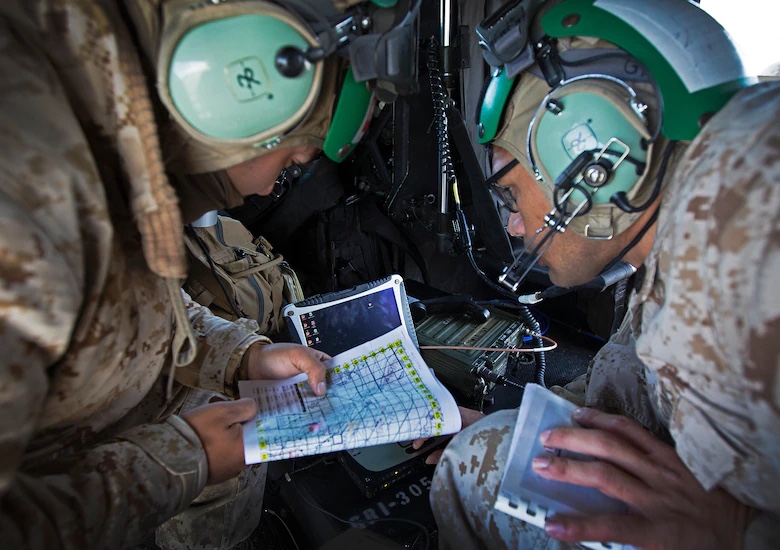

“Fielding a tactical radio that allows data to be transmitted helps advance JADC2 because the framework itself requires connectivity at all levels. In order to fully realize this vision across the Department of Defense, our team has worked tirelessly to develop a radio that closes communications links between the Corps and the joint forces; prevents communications from being compromised; ensures resiliency; and operates on the right waveforms,” said Lt. Col. Joshua Kapp, product manager for ground radios.

But as Kapp knows well, one of the first steps in creating a modern communication architecture is acquiring – and sustaining — tactical ground radios that operate on reliable, secure, and flexible communication networks. In today’s defense landscape, these systems operate on high-frequency, ultrahigh-frequency, very high-frequency bands, satellite communications and multiband radios.

“Collectively, our mission is to field and sustain tactical radio equipment that enables command and control and the situational awareness at echelons and elements across the MAGTF and provides a line of sight beyond line-of-sight secure voice data,” Kapp said in a recent MARCORSYSCOM podcast. “It’s a long way of saying that we cover all of the tactical radios in the Marine Corps.”

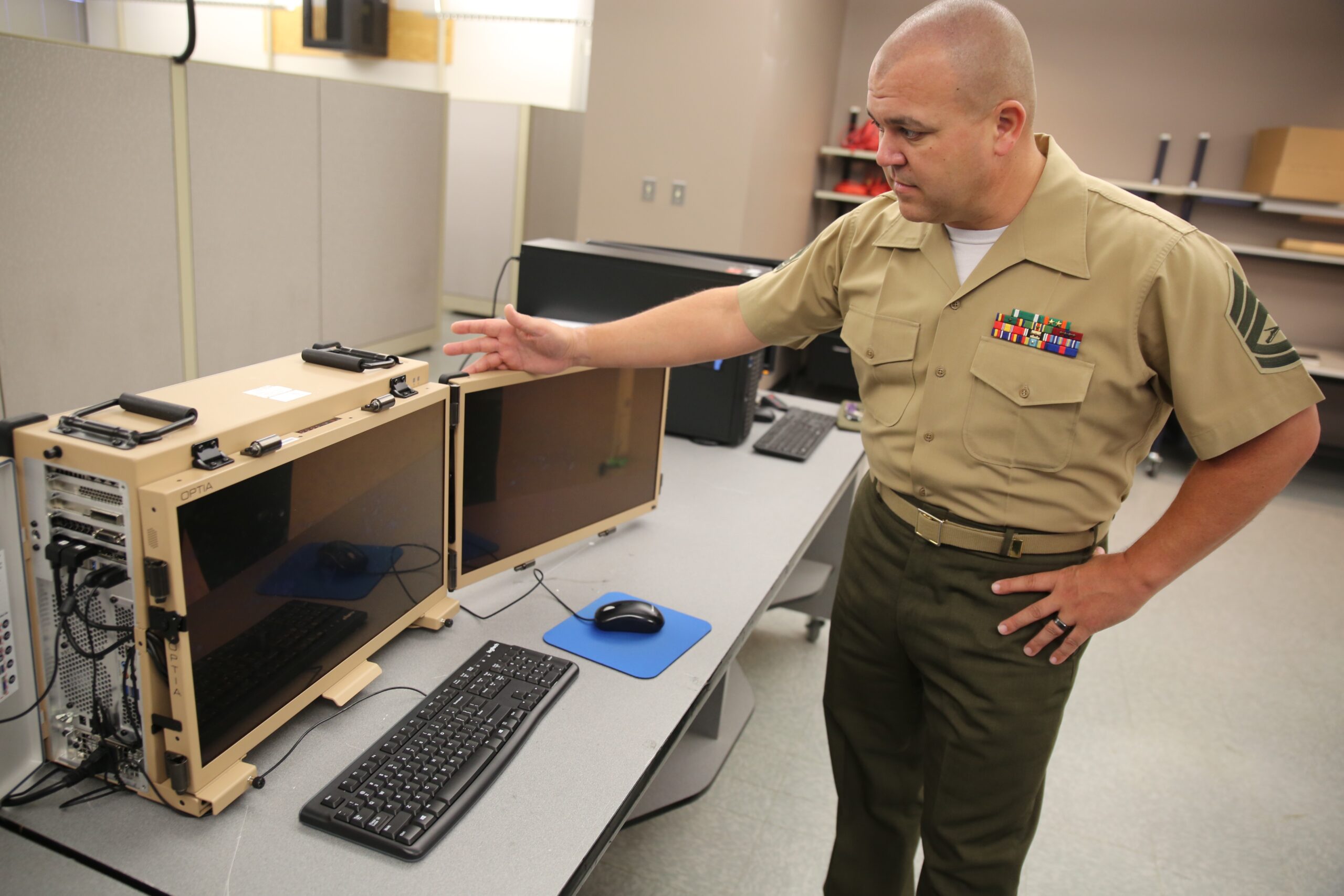

Acquiring the correct systems to ensure the lethality of the modern warfighter is no easy task – especially when the team must maintain the 85,000 radios currently owned by the Corps, in addition to fielding an additional 34,000 radios over the next five years.

“We’re in a consistent cycle of contract prep and award, product testing, software and firmware updates, technological evaluations, waveform development, FMF engagement, and support and sustainment efforts,” Kapp noted. “Without a doubt, we also spend a considerable amount of time doing commodity management and integration activities across the Command and [other] Services.”

According to Sessions, fielding of the new multichannel handheld radios will begin in the first quarter of fiscal year 2024.

Driving a highly professional acquisitions program has also benefited the Corps, however, and Sessions was quick to note that the recent industry contract for handheld multichannel radios ended up saving the Corps millions of dollars.

“We’re talking about an initial savings of $82 million. Beyond that, we’ve negotiated 10 years of support and an agreement to allow our Marines to do Level 3 maintenance without voiding our warranty. That isn’t something a radio vendor has allowed before,” Sessions noted.

But Kapp believes his team’s success wouldn’t be possible without the hard work and dedication of his team members — many of whom are Marine Corps veterans.

“What I really appreciate about the team is their investment. It’s something I see from government, civilians, and contractors alike. What you may not know, however, is that the vast majority of my team is made up of past Marines. They have children, brothers and sisters who are still serving,” Kapp said.

“Inevitably, this means that they bring a ton of dedication into the work that they do. It’s not just about being successful… there’s true passion behind the work they do because they know what the end result is.”

Editor’s note: Learn more about Marine Corps ground radio acquisition efforts on MARCORSYSCOM’s Equipping the Corps podcast, featuring Lt. Col. Josh Kapp, here: www.dvidshub.net/audio/71291/equipping-corps-s2-e4-ground-radios-with-maj-joshua-kapp

Johannes Schmidt, Marine Corps Systems Command

Photos by Cpl Nghia Tran and LCpl Brendan Mullin