Archive for 2013

Forces Focus – Take A Look At The 1st Special Operations Wing

Tuesday, November 5th, 2013What’s Really Going On With Those DTOM Flags and NSW? UPDATED

Tuesday, November 5th, 2013In the last few days, a story has emerged in the mainstream media regarding the Naval Special Warfare (NSW) community, specifically the SEAL Teams, being ordered to cease and desist wear of the Don’t Tread On Me (DTOM) patch many wear on their uniforms. Although NSW personnel have been ordered to quit wearing the patch on their left arm immediately, there is more to the story and the background isn’t what is being discussed in the mainstream. You are being told half-truths by people who don’t know what they are talking about. This has nothing to do with politics and everything to do with getting the paperwork done.

Roughly two years ago, East Coast-based NSW units began working with one of the manufacturers, authorized by contract to produce items in AOR1 and AOR2, to develop an Identify, Friend or Foe (IFF) patch which would incorporate the new NSW patterns and IR material. The intent was to create US Flag patches which could be worn in garrison, but incorporate the IR sheet material found in traditional IFF flag patches worn down range by all services. The intent of this was to reduce the cost associated with buying multiple types of patches and keep the uniform looking professional. In the process of working on the laser-cut US Flag patches, the manufacturer was asked if it was possible to use the same process in order to create a Don’t Tread On Me patch for personnel to wear.

In the midst of developing the new flag patches, the Navy rolled out the Navy Working Uniform (NWU) Type II and III with Velcro on the shoulder pocket flaps. Ironically, there was no provision in the Navy Working Uniform Manner of Wear regulation allowing flag patches to be worn outside of tactical, training, or deployed situations. As a result, the uniform looked somewhat ridiculous with bare Velcro. Once the prototype laser-cut AOR1 and AOR2 patches were ready for evaluation, the East Coast-based NSW Group sought authorization to wear the reversed US Flag on the right shoulder and DTOM on the left because the patches were made of the same material as the uniform and looked more professional than leaving one or both shoulders bare Velcro.

Fast forward two years and like all things, people begin to take notice and ask, “Why are they doing that?” In this case, NSW never fully ran the issue of wearing patches in the NWU to ground and eventually someone noticed the community was not technically complying with the uniform regulations. As a result of the NWU regulations never being updated to reflect authorization to wear the patch in garrison, the cease and desist order issued by direction of Naval Special Warfare Command, is enforcing the actual uniform regulations issued by the Navy Uniform Board.

There is no conspiracy here folks; no one in the Administration is attributing the patch to extremist groups or anything of that nature as some recent stories have indicated. And for anyone who thinks that is the case, if you take a look at the bow of any US Navy ship today, tomorrow, or next week, you’ll see the Navy Jack flying which is the same flag represented by the Don’t Tread On Me patches in question. This recent issue of patch removal is just the NSW Senior Enlisted community doing what they are supposed to do, enforcing the uniform regulations until those regulations are changed or modified through the proper process. But have no fear, the order to stop wearing the patch does not apply to wear in tactical, training, or deployed environments.

Update WARCOM sent out an email that the issue has been resolved and NSW personnel may wear the Navy Jack both in CONUS as well as deployed. The decision was directed by ADM Losey and approved by the MCPON. The WARCOM clothing instruction will be updated.

The Operational Dangers of Specialized Camouflage Patterns

Monday, November 4th, 2013I’ve been on record as opposing the adoption of specialized, area specific camouflage patterns. Basically, I’ve got two arguments against the concept. First off, is logistical. It’s extremely difficult to ensure that the right Soldier has the right pattern in the right environment. Shorten the timeline (as in contingency ops) and it’s all but impossible. And that issue leads to my second concern, operational effectiveness. Perhaps our friend Cal the Chameleon from the cartoon “Unnatural History” can best demonstrate what happens when you don’t have the right pattern for the environment you’re entering.

What Did SSD Say When This Whole Army Camo Program Started?

Monday, November 4th, 2013The Way Back Machine takes us to December 13th, 2010 when I published this opinion piece regarding the Army’s upcoming requirement for a new family of camouflage.

I attended the Army Camouflage Improvement Industry Day held last week at what was once called Harry Diamond Labs in Adelphi, Maryland. Before I can comment on any of the information presented at the conference, and there was a lot, I feel it is important that I address the underlying issue at hand; the requirement itself.

Overall, is the requirement valid? In my opinion yes, but to a point. The Army should continually assess technologies to reduce the signature of the American Soldier. My issue is with the implementation. The program’s timeline, which I will discuss in more as the week progresses, ends with a plan of action being presented to Army leadership at the end of FY12. This means a decision won’t be made until then at the earliest, with implementation not taking place until well into FY13. The problem with this? We are at war now.

My biggest issue with this program is that the authors of this latest requirement have failed to learn from the past, and worse yet, the recent past. In fact, by working to field multiple specialized patterns, they are repeating failures from THIS war. Prior to the adoption of UCP, the US Army relied upon Woodland and Desert camouflage patterns. All Soldiers were issued Woodland clothing and equipment regardless of posting. The 3-Color Desert pattern was considered specialty equipment and only issued to select personnel based on operational requirements. Unfortunately, during 1991’s Operation Desert Storm many American troops wore Woodland clothing due to the shortage of desert issue. Ten years later, this same situation was repeated during the early days of Operation Enduring Freedom and what’s worse, once again during Operation Iraqi Freedom. Unlike post 9/11 operations, the military had ample time to procure and issue specialized desert clothing and equipment prior to the commencement of hostilities with Iraq, yet they failed to accomplish that task. Consequently, we had troops that wore a combination of desert and woodland clothing while some received no desert issue at all. UCP was envisioned to overcome these issues. One pattern for clothing and equipment so that Soldier’s could deploy at a moment’s notice, anywhere in the world. While the implementation was lacking, there is no need to throw the baby out with the bath water.

I have some relevant experience here. I spent much of my career in the 72-hour contingency business serving in both the Army and Air Force. Even in a unit that issued all deployable personnel desert equipment, September 13th 2001 found me rounding up DCUs and other field equipment for support troops that were not slated to ever go to war. Their specialties were normally accomplished at home station but the unique nature of the burgeoning War on Terror required them to deploy forward. These technicians literally reported for duty that morning with news that they leaving on a flight that evening for an Intermediate Staging Base in the Middle East. Fortunately, we kept ample supplies of OCIE on hand, but this still held up their processing for deployment. Standing in line for uniforms is the last thing you want to do when you are deploying that same day. Make no mistake, had we not had unit stocks of equipment, these men would have deployed in the wrong uniform. So long as we issue specialized patterns, individuals as well as entire units will risk deploying in the wrong uniform.

The Family of Camo Pattern program will produce exactly the same set of circumstances in future conflicts. Soldiers will fight with the equipment they have rather than the equipment they desire. The perfect piece of kit sitting in a warehouse somewhere has zero effect on the outcome of a battle. And really, what’s worse, is that two or even three patterns won’t be enough to truly provide 90% or better camouflage in the world’s disparate environments. A woodland pattern will still have to be a compromise for all woodland or jungle areas. The same holds true for desert. Based on this current requirement, the Army is asking for generic patterns that will work well in some environments and not so great in others. The chance that a Soldier’s camouflage will work against him actually increases based on this requirement. The more specialized patterns the Army develops, the fewer places the Soldier can use them. At the conference, I kept hearing that this is about performance and not a fashion show, but spending money on a camouflage pattern that won’t work most places sounds like a fashion statement to me.

Which brings me to the next point. What makes this issue even worse is that it seems that no one is taking into account the shrinking defense dollar. Purchasing multiple patterns is not cost effective for the standing Army and associated Reserve and Guard force that our country fields. Consider that the Army issues a garrison uniform (ACU) as well as specialized combat apparel (FRACU and ACS). The Basis of Issue for these garments multiplied by the size of the force calls for a uniforms requirement in excess ten of million. And that is just to start. Factor in sustainment and you can see that we just can’t afford multiple patterns.

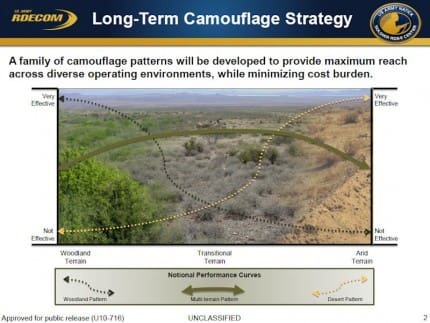

While dedicated camouflage patterns are fantastic in the environment they are designed for, they work against the Soldier in other environments. As you can see in this graphic shown at the Industry Day conference, the Army has learned that Soldiers in Afghanistan traverse multiple micro environments during a single mission. If the Army adopts dedicated patterns, Soldiers will potentially be safe as houses in one micro environment, but as their mission progresses, their uniform will do the enemy’s work for him, making them stick out like the proverbial sore thumb.

As you may have read in Kit Up!, the Army is not going to include the current Army standard UCP as a baseline in the evaluation phase of the solicitation. Essentially, COL William Cole, PM for Soldier Protection and Individual Equipment said that the 2009 camo study showed that UCP was not an effective pattern. Instead, they are going to baseline results against OCP and what is essentially already a DoD Family of Patterns, MARPAT Woodland and Desert and their cousins AOR 1 and 2 which all share similar geometries.

In 2009, the Army chose MultiCam for use as the Operation Enduring Freedom Camouflage Pattern (OCP) based on a rigorous test protocol that will essentially be repeated in this latest search for a Family of Camo Patterns. While testing focused on the Afghanistan theater, candidate patterns were assessed in a variety of micro terrains. In that test, MultiCam proved to be effective 70% or better in EVERY environment it was pitted against. No other pattern reached this mark.

OCP is available now. As a GOTS solution, it has been tested, and is in production. Of all of the multi-terrain or “transitional” patterns available during the last round of testing, it proved to be the most effective. Consequently, the Army adopted it.

In the end, the requirement is there. It is important for industry to put their best foot forward and participate. But, in my opinion, the Soldier is losing out as the can is kicked down the road. Remember, a bird in hand is worth two in the bush. Let’s field a viable solution now and take our time with the science projects.

-The Editor

Know Your Knife Laws

Monday, November 4th, 2013KnifeUp.com has a simple to use interactive web page that offers knife laws in plain English. Just click the image below to hit the website and start learning about knife laws, state by state.

As always, we suggest you use the guide as a starting point and contact local authorities to verify local knife and firearms laws.

Will Contour Be Back?

Monday, November 4th, 2013If Clarke Capital Partners has anything to say about it, Contour, makers of action cameras is coming back after closing its doors in August. Clarke Capital Partners were the high bidders at $1.925 million for the defunct company’s assets during a competitive auction by a court-appointed receiver. Geek Wire reports that while the sale has been approved by the court, it still needs to be finalized by the parties. CCP was an investor in Contour before it went out of business. Apparently, operating capital was its major challenge, defaulting on nearly $7.5 million in loans prior to closing.

We wish them well as the Contour has been very popular with shooters due to its tubular shape and mounting options,

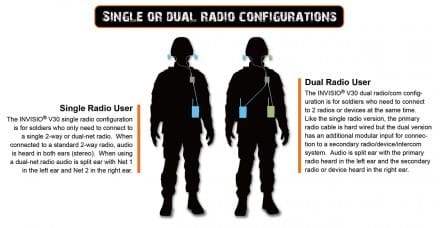

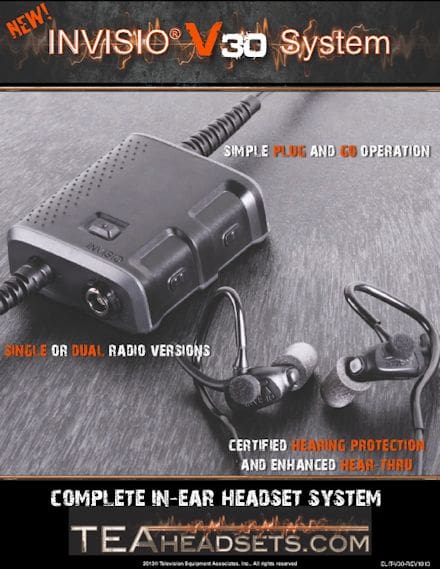

INVISIO V30 Specs from TEA Headsets

Monday, November 4th, 2013We had a chance to see the new INVISIO® V30 at AUSA. It is simple, all-in-one headset system utilizing the utilizes the INVISIO® X5 dual in-ear headset for high noise environments. It is plug and play requiring no calibrating.

The INVISIO® X5 headset features the patented and proven bone conduction microphone. Speech is captured in the ear via vibrations from the user’s jawbone. These vibrations are converted into sound, delivering crystal clear communication under extreme and noisy conditions, even when whispering or worn under a gas mask.

TEA Headsets has created this ebrochure for their new INVISIO V30 that includes technical specifications, diagrams, configurations, etc.

Note: Currently available for select military radios only (PRC 148/152)

Gerber Gear Round Up – Bear Grylls Compact Multi-Tool

Monday, November 4th, 2013As you know, we’ve got Scouts here at SSD. Each week over on Tactical Fanboy they cover another product from Gerber. Awhile back I went out and bought one each of most of the available Bear Grylls products. We expanded it with a few other Gerber products. The deal is that they can reach into the box and try out an item so long as they write about it afterward. This is one of the write ups. Remember, it’s written by a kid.

The Bear Grylls compact multi-tool features ten components:

It’s lightweight and compact, perfect for fitting on a keychain or in a pocket. External components and nail nicks allow for easy access to tools.

I like the variety of tools present on this multi-tool. The nail nicks make them easier to get out. Having a lanyard ring on the tool is good because it can be kept on a keyring or secured to other gear. I also like the small size, but at the same time that makes it a bit harder to find if you misplace it.

www.gerbergear.com/Survival/Tools/Survival-Series-Compact-Multi-Tool_31-000750