It’s Friday and this week is our second installment of our OEM Partner Series. We’ll take a look at an OEM company that FS has partnered with and the equipment they produce. Today we are checking out an all-American company, Tuff Possum Gear.

How has Tuff Possum grown over the years?

When we launched as a brand in the fall of 2017, it was just me, Jayberry, with a small sewing machine on the kitchen table and a few rolls of fabric, webbing, etc. We grew exponentially, until we reached some serious chokepoints in our growth towards the summer of 2019. We needed to scale our production and incorporate design elements involving things like laser cut laminates, but being self-funded meant those things were difficult to do in the timeframe and budget we had. So we started looking around for a manufacturing partner who would have the infrastructure to help catapult us forward.

There are options for private label manufacturing all around the world, how did you find us and why did you ultimately choose FirstSpear OEM manufacturing?

We first found FirstSpear through another OEM customer of theirs, Hill People Gear. I have used Hill People gear products for years, and I trust the judgement of the fine folks at HPG when it comes to human character. We talked to a number of industry folks, toured the factory in Fenton, Missouri, and were impressed by not just the dedication to quality and innovation, but the professionalism of the people as well.

Why was Made in the USA important to the brand?

For one, I know that FirstSpear and the wonderful men and women working there share the same ideologies as we do; namely the importance of life and liberty. Of the freedom to build and grow. To create value and be rewarded for it.

As such, I know that the employees are well taken care of and are working in a professional, healthy environment. I know that we can trust our manufacturing partners and that it is merely a few hours drive to visit the factory in person. It is important to me that I am supporting American jobs and a robust domestic manufacturing culture, when we are surrounded by a world that seems bent on becoming even more fragile and dependent on our nation’s enemies for our supply chain.

I also have a strong sense of gratitude for the land and the country that has given us so much. Despite its flaws, it has stood as a bastion for freedom and righteousness in a world of darkness. And it is truly a land of opportunity. A land that has been fertile ground for generations of our forefathers. American manufacturing is important to us as a way of giving back. Of supporting the industry, the grit and tenacity, the people, and the families that compose this great country.

Why was the Shackleton EDC Satchel created? Can you dive into the relationship between that and the Med Pouch?

The Shackleton EDC Satchel was the result of 8 years of filling the need for a compact shoulder bag to carry the tools that make life flow smoothly and solve problems when they arise, after the manner of the “possibles bags” of frontier trappers or the famous Indiana Jones, World War II era gas mask bag.

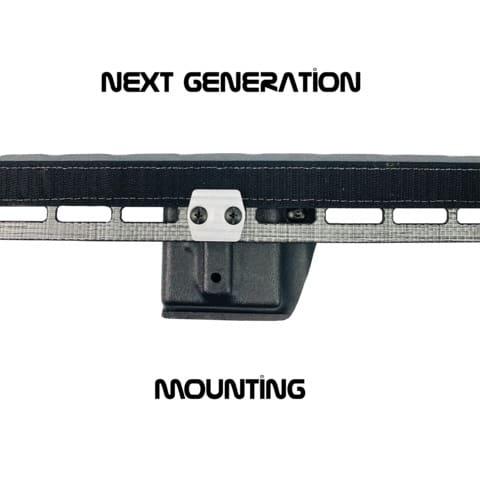

It needed to be clean and unassuming on the outside, with the right balance of organizational pockets and freedom of modular customization. Partnering with FirstSpear allowed us to take advantage of their 6/12 laser cut, velcro compatible laminates. We put a full width panel of it across the back of the Shackleton’s interior, allowing the customer to use any manner of PALS/MOLLE pouches, velcro hook backed pouches, as well as clip smaller items such as flashlights, pens, knives, etc. in the loops.

We believe in being prepared to protect the innocent and save a life if need be. This means not just having the tools to stop a threat, but having the tools to patch up an injured person, whether that is from a deadly force encounter or a motorcycle accident. The Med Pouch is the result of my need for a removable “pod” that would hold a solid selection of items to address massive hemorrhaging and airway on a trauma victim (ie. tourniquet, compressed gauze for wound packing, compact chest seals, NPA, gloves, etc.), and attach via velcro to the inside of the Shackleton EDC Satchel or any Velcro loop lined bag.

Always at hand and always ready to “rip” out and go to work. The Med Pouch was an instant hit and is still one of my favorite pieces of gear when paired with the Shackleton.

What sets your products apart from others on the market?

Customer involvement and feedback combined with our commitment to high standards of quality and design, make for a winning recipe. Rather than some corporate designer in an ivory tower, our gear is the result of “boots on ground” real world experience and needs.

As the main product designer and owner/operator of Tuff Possum Gear, I “keep my hands dirty.” Using gear, talking directly with the customers, and always on the lookout for ways to improve. That affects every aspect of our products from customer service to design to quality control and culture.

What’s your company’s motto and what can we expect from Tuff Possum in the future?

“Equipping you with trustworthy adventure gear, built for those who GO places and DO.”

We have traditionally been a soft goods company and had an absolutely amazing year in 2020, doubling in growth and launching many of our now signature pieces (many manufactured by FirstSpear). Looking back, it was really building out a foundation for this year. Now we are broadening our horizons and adding a host of new designs. You can expect not only a variety of new nylon goods, but also a selection of designs in the tools and hardware category, from pack hanging hooks to lockpicks and even a knife design or two.

For more information, check out tuffpossumgear.com/shop.

For more information about FirstSpear and OEMs, contact sales@first-spear.com.