Palmetto State Armory has announced that they’ll be partnering with Hornady to bring more 338 ARC options to market.

From new developments in the JAKL and Sabre lines to ammo from AAC, this project promises to be big.

Palmetto State Armory has announced that they’ll be partnering with Hornady to bring more 338 ARC options to market.

From new developments in the JAKL and Sabre lines to ammo from AAC, this project promises to be big.

FORT CAMPBELL, Kentucky — Roughly 200 Airborne Infantry Soldiers of the 101st Airborne Division (Air Assault) are running the Next Generation Squad Weapon (NGSW) system through its paces here from Sept. 1 to Oct. 30.

Soldiers from Alpha and Bravo Company, 1st Battalion, 506th Infantry Regiment are taking part in an operational assessment (OA) featuring a range of weapon configurations, force-on-force engagements and static live-fire ranges.

It is a key step in modernizing the combat force and aims to impact over 120,000 U.S. Army Soldiers, according to Mr. Elbert L. Grayson, Supervisory Military Test Plans Analyst, Maneuver Test Directorate, U.S. Army Operational Test Command.

“The Army needs equipment to continually evolve, to meet the threat of our adversaries,” said Grayson.

The NGSW system will be the next stage in that evolution.

“Information is needed to make improvements to the NGSW that will benefit America’s most precious resource, our Soldiers,” Grayson added.

The new weapon system is slated to replace the M4 carbine and M249 squad automatic weapons, representing a significant advancement in firepower, range and accuracy.

“Having seen the capabilities of the 6.8 [mm] round, I have confidence that it will easily do in one to two rounds, what the 5.56 [mm] did in two to four,” said Capt. John M. Green, Commander of A-CO, 1-506th, 101st ABN DIV.

Direct feedback from U.S. Army Soldiers provides invaluable insight to ensure future warfighters receive the best possible equipment when it matters most.

“The force on force is really exciting, really fun, getting in there and doing training against human beings, not just targets, and actually squaring off [against another] unit making plans and objectives, I think it is a really good training experience for sure,” explained Sgt. Todd Smallwood, First Squad Team Leader, A-CO, 1-506th, 101st ABN DIV.

According to Grayson, the NGSW testing is being conducted under the most rigorous conditions to simulate real combat and ensure that the weapon can meet the demand of future conflicts.

“We have been doing the operational assessment on the NGSW weapons, the XM7, the XM250, and also with the XM157 scopes on the weapon systems,” said Smallwood. “We’ve been doing quite a bit of ranges, and pop-up targets, trying to recreate platoon assault objectives.”

Besides standard training environments, the operational assessment was designed to simulate combat as closely as possible.

“The capability of the [6.8mm] round being able to puncture and turn cover into concealment, I think it will make a huge difference in urban and forest environments,” said Smallwood.

Soldiers were challenged to perform individual movement techniques (IMT) while engaging targets up to 300 meters away. This IMT lane requires Soldiers to bound, low-crawl, and high-crawl while maintaining accurate fire, ensuring that the weapon performed reliably under strenuous conditions.

They had to complete the course while under simulated combat stress, pushing their physical and mental limits.

“We did 72 hours of force-on-force (FOF), urban rifle marksmanship (URM), and we’re going to finish with a stress shoot,” said 1st Sgt. Barron C. Garrard, First Sergeant of A-CO, 1-506th, 101st ABN DIV. “I think it [the NGSW] will change daily life in the way that we fight.”

In preparation for future operational environments, Soldiers also tested the NGSW in simulated chemical, biologic, radiological, and nuclear (CBRN) environments.

“I like the fact that the testing of equipment has a possible impact on the next generation Soldiers that will be using it,” said Grayson. “My son is a Soldier that may use equipment that I have had a part in testing, so I’m motivated to provide the most accurate data for Army leadership to make the most informed acquisition decision.”

This critical aspect of the assessment ensured that the weapon system can be operated even in the aftermath of a chemical, nuclear or biological environment.

“The NGSW’s advanced capabilities and comprehensive training program will significantly enhance the lethality and survivability of our troops,& ensuring they are prepared for the challenges of future combat operations,” said Mr. Troy , Test Officer in Charge with MTD. “The 6.8mm round offers superior ballistic performance and the NGSW overall represents a significant leap in lethality.

“I feel privileged to be part of this transformative period for the Army,” Willey continued. “Working with the Soldiers who are assigned this system during the assessment is an absolute honor.”

By Mr. Thomas Mort, Audio Visual Specialist, and Maj. Thomas Lorenson, Senior Test and Evaluation Officer, Maneuver Test Directorate, U.S. Army Operational Test Command

We initially showed you the FN Lightweight Intermediate Caliber Cartridge (LICC) Individual Weapon System (IWS) just before SHOT Show 2023. Since then, it’s undergone some improvements. FN America exhibited version 2.2 of the IWS at this year’s AUSA.

Here we see the 11.5″ Close Quarter Battle version with the 2.1 selector (it has been modified slightly more based on user feedback) and slightly larger charging handles as well as an improved buttstock mount. Changes to the operating system have also improved the feeding of the carbine.

This is the latest version of the dedicated magazine, produced by Magpul.

The carbine and machine gun are both chambered to fire the Lightweight Intermediate Caliber Cartridge (LICC) in .264 USA which was initially developed by the the Army Marksmanship Unit. As you can see, the case is steel.

Here’s a look at the stock which both folds and is collapsible.

Seen here is the latest suppressor, from HUXWRX.

In mid-November, FN will join the Irregular Warfare Technology Support Directorate (IWTSD) program office in delivering carbines, machine guns, and ammunition to the SOF user community for evaluation.

Warfighters will leverage 1,280 Green Ammo electronic blank kits for realistic training across individual and collective exercises

SKIEN, Norway, Oct. 16, 2024 — Green Ammo, AS, developers of the industry’s only drop-in electronic blanks system for live weapons offering 100 percent integration with tactical training programs, today announced that it has been awarded a total of $5.8 million in contracts with the Department of Defense.

Across two contracts, executed in August and September, Green Ammo will deliver nearly 1,300 units of its drop-in electronic blanks (E-Blanks) training kits to support realistic tactical training exercises. The military-grade, pressure-tested E-Blanks kits offer compatibility with M4, M249, and M240 weapon systems, enabling warfighters to train with the right weapons for the theater-specific threats they may face. The units are expected to electronically fire an approximate total of 325,000,000 rounds (~250,000/each) before any components need to be exchanged, replacing the same number of traditional blank rounds and saving millions of dollars in ammunition costs.

Green Ammo is a Norway-based defense technology company with operations in the United States, dedicated to developing, manufacturing and delivering electronic blank ammunition for tactical training applications. The company’s E-Blanks kit empowers warfighters to train with known weapons through a patented, 100-percent drop-in module that can install and deploy E-Blanks in under a minute for a realistic, safe, sustainable and cost-effective alternative to live or traditional blank ammunition. In preparation for the initial delivery of the E-Blanks kits, Green Ammo conducted an initial train-the-trainer event. Attended by senior trainers and officers, the event introduced the E-Blanks system to the training cadre and supported discussions on implementation and logistical considerations.

“We’ve worked hard to deliver a solution that serves as an alternative to traditional ammunition with the added benefits of time and cost savings, and we’re pleased that E-Blanks can help ensure servicemen can continue to train effectively, even with the impact of the global ammunition shortage,” said Rolf Inge Roth, CEO of Green Ammo. “By providing E-Blanks kits for individual and collective training, we can help the Department of Defense overcome these limitations to support successful pre-deployment training with the additional benefits of simplified logistics and increased safety.”

The delivery of 1000 M4, 170 M249 and 110 M240B drop-in kits will be completed by the first quarter of the 2025 fiscal year. To learn more about Green Ammo’s patented electronic blank technology and its applications, visit www.greenammo.com.

Primary Weapons Systems announces their collaboration with Hornady on the new 338 ARC rifle cartridge. PWS will support the collaboration with their adjustable long-stroke piston driven rifles and uppers, the UXR Multi-cal rifle and a 338 ARC compatible BDE suppressor.

“We’re thrilled to announce our partnership with Hornady on this exciting new caliber. The combination of BDE suppressors and the Long Stroke Piston System used in our rifles, creates an optimal scenario for shooting 338 ARC, given that it’s geared toward hard hitting subsonic performance. Together with Hornady, we’re not just launching a product; we’re setting new standards and redefining what’s possible in our industry.”

– Ben Fleming, President of Primary Weapons Systems

JACKSONVILLE, AR, (October 11, 2024) – SIG SAUER is proud to announce the official opening of the Jacksonville Arkansas Ammunition Center (JAAC) on the SIG SAUER Ammunition campus. The advanced manufacturing facility in Jacksonville, Arkansas brings 210,000 additional square feet of high-tech modern manufacturing in support of the U.S. Army Next Generation Squad Weapons and family of 6.8 Hybrid Ammunition.

“In just one year, we have built a manufacturing facility that will stand for generations with the mission to provide our soldiers an ammunition technology advantage in lethality and overmatch versus our enemies,” began Ron Cohen, President and CEO, SIG SAUER, Inc. “This incredible facility gives us the ability to significantly scale manufacturing and grow our output for years to come – and this is only the beginning.”

SIG SAUER’s $225 million dollar investment in facilities and equipment will yield more than 675 jobs and over $300 million in total economic impact in Arkansas. Since the 2016 establishment of SIG SAUER Ammunition in Jacksonville, Arkansas, the operation grew dramatically, now producing ammunition for all branches of the U.S. military, special forces and our NATO allies across six facility campus spanning half-a-million square feet across its six-facility campus.

“Arkansas is proud to be home to this facility. It isn’t just a quarter million square feet of manufacturing space and more than 600 jobs; it reinforces Arkansas’ place as the arsenal of America,” said Governor Sanders. “To Ron and all the team at SIG SAUER: thank you for believing in Arkansas and investing in our state. And to everyone who played a role in bringing this facility here: thank you for your hard work.”

The focus of the JAAC is advanced ammunition, strengthening the industrial manufacturing base for the U.S. Department of Defense. Through a strong cooperative effort, SIG SAUER and the U.S. Army realized this scalable manufacturing capability in just over 2 years.

“This facility exemplifies the significant investment being made to enhance capacity and capabilities to enable ammunition production at scale in direct support of our Warfighters,” said U.S. Army Joint Program Executive Officer for Armaments & Ammunition, Maj. Gen. John T. Reim. “It is amazing to see what the team has accomplished in two years with the introduction of the NGSW and the new 6.8mm round that ensures, when called upon, our Soldiers are equipped with the safest, most reliable, and lethal munitions, enabling them to decisively fight and win our Nation’s wars.”

Governor Sarah Sanders joined by Senator John Boozman; Ron Cohen, President and CEO, SIG SAUER, Inc.; Maj. Gen. John T. Reim, JPEO Armaments and Ammunition; Ron Goslin, Chief Operating Officer; Katelyn Wilson, VP Strategic Capture Operations; Sean McGee, Director of Ammunition Operations; and Jason Imhoff, Chief Technology Officer, Ammunition to cut the ceremonial ribbon.

“We live in precarious times and SIG is in a unique position to participate in the herculean effort to change our ground forces, and better protect our country and our allies,” concluded Cohen.

Please enjoy the event photo gallery: JAAC Grand Opening Photo Gallery

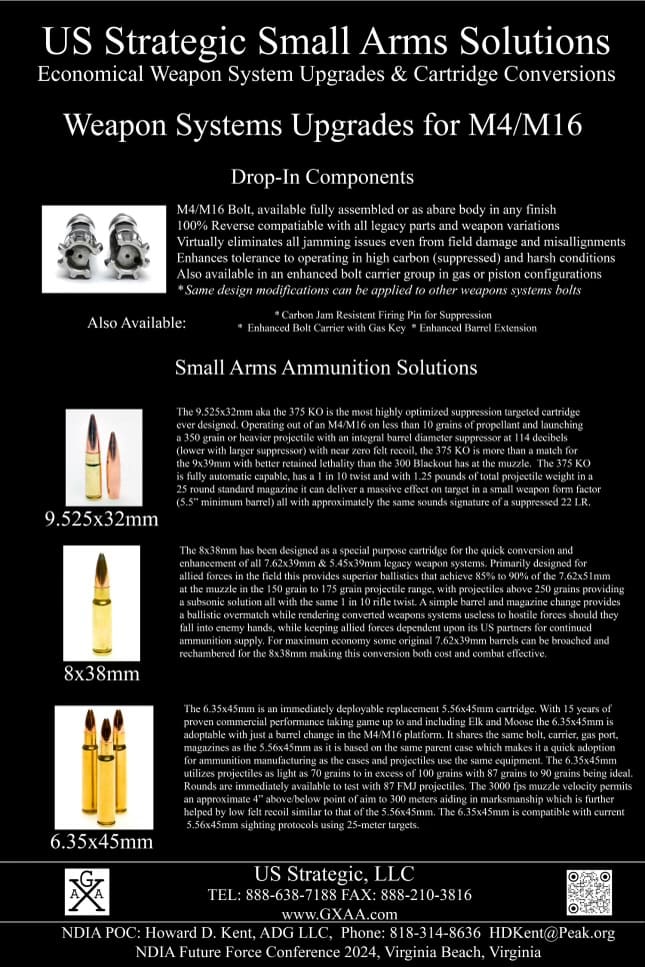

We are back with another poster from the recent NDIA Future Forces Conference in Va Beach.

This one depicts alternative caliber options as well as drop in components to facilitate the transition from 5.56 NATO.

POC data is on the poster.