REDSTONE ARSENAL, Ala. — The Army’s Future Vertical Lift program took a major step forward as the Future Long Range Assault Aircraft, or FLRAA, program entered the next major phase of development when the Army announced the approval of the FLRAA Milestone B Acquisition Decision Memorandum on August 2, 2024.

The decision came after the successful FLRAA preliminary design review in April and a meeting of the Army Systems Acquisition Review Council in June. After reviewing FLRAA affordability, technological viability, threat projections and security, engineering, manufacturing, sustainment and cost risks, the ASARC confirmed that all sources of program risk have been adequately addressed for this phase of the program. Milestone B allows the Army to exercise contract options and continues development of the aircraft as it now enters the engineering and manufacturing development phase.

“This an important step for FLRAA and demonstrates the Army’s commitment to our highest aviation modernization priority,” said the Army acquisition executive, the Honorable Douglas R. Bush. “FLRAA will provide assault and MEDEVAC capabilities for the future Army, adding significantly increased speed, range and endurance.”

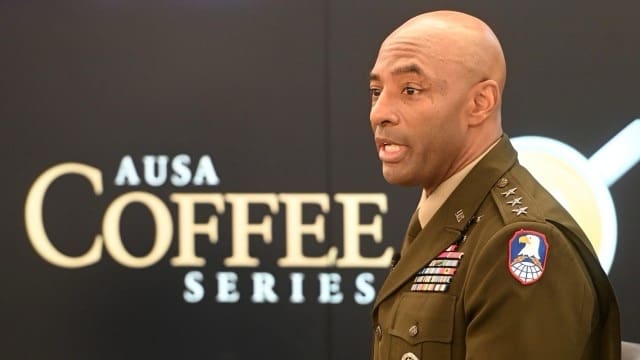

“This is an exciting day for the Army … and more importantly for our Soldiers. The FLRAA provides truly transformational capability to Army aviators as we uphold the sacred trust with the Soldier on the ground,” said Maj. Gen. Michael C. McCurry, 17th chief of the U.S. Army Aviation Branch. “Future battlefields require expanded maneuver, the ability to sustain and provide command and control across vast distances, and of course, evacuate our wounded. All of these apply to both conventional and special operations forces. With roughly twice the range and twice the speed, FLRAA brings unmatched combat capability to the joint force.”

The Army awarded the FLRAA Weapon System Development contract to Bell Textron on December 5, 2022, and it includes nine options. The Milestone B allows the Army to exercise the first option which includes detailed aircraft design and build of six prototype aircraft. The Army is planning for the first FLRAA flight in 2026 with low-rate initial production scheduled to begin in 2028 and initial fielding activity in 2030. The Army will continue to review and refine the schedule as necessary based on the contract award and the latest program activities.

“PM FLRAA and our Team of Teams across the aviation enterprise are working hard to make sure that we get it right,” said Brig. Gen. David Phillips, Program Executive Officer, Aviation. “We will deliver a next generation combat capability that meets the Army’s goals for affordability, survivability, maintainability, reliability and safety.”

“The FLRAA Milestone B decision is another successful step of a deliberate modernization effort by the Army,” said Brig. Gen. Cain Baker, director for the Future Vertical Lift Cross Functional Team. “The many stakeholders, including academia and industry, have worked hard to ensure rigorous technology development and demonstration and have informed FLRAA requirements and affordability. FLRAA’s speed, reach and survivability will be key to transforming U.S. Army maneuver.”

“I am very proud of the FLRAA team. We’ve maintained a deliberate balance between sustaining program momentum while maintaining technical and acquisition rigor,” said Col. Jeffrey Poquette, FLRAA project manager. “Using digital engineering as a key part of our ‘go slow to go fast’ approach has helped to accelerate the program by investing in requirements development up front.”

FLRAA will provide transformational capability for ground forces and aircrews with speed, range, and surprise to present multiple dilemmas to the enemy. It will expand the depth of the battlefield, extending reach to conduct air assault missions from relative sanctuary while enabling us to rapidly exploit freedom of maneuver to converge ground forces through decentralized operations at extended distances. FLRAA’s inherent reach and standoff capabilities will ensure mission success through tactical maneuver at operational and strategic distances.

As the Army transforms to meet an uncertain future, FLRAA is one of many modernized capabilities that will help ensure the Army of 2030 and beyond is ready to win when the nation calls.

By PEO Aviation