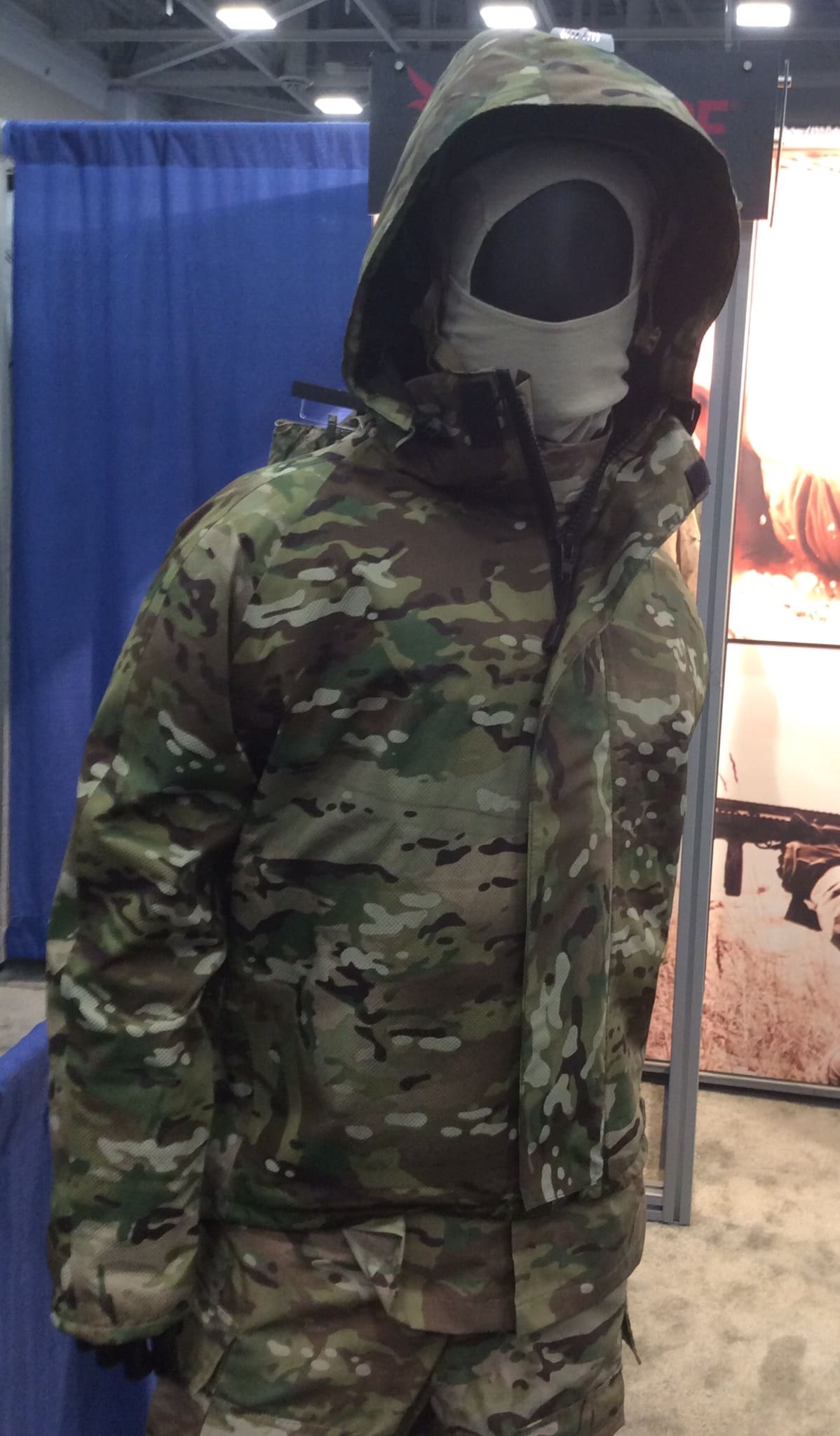

During SHOT Show I had an opportunity to check out First Tactical’s new Defender Series. I was impressed by the fabric choice as well as the design features.

First off, the Defender series is the first to use a new NYCO fabric featuring mechanical stretch. The fabric was engineered for wear in warm and humid weather and is moisture wicking. First Tactical added features like vented crotch, knee, side gussets, and mesh pockets to help make life more bearable during hot weather wear. In addition to the fabric’s mechanical stretch, First Tactical designers also created a garment with running gussets throughout, a comfort waist, and articulated knees and elbows.

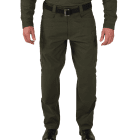

The Defender series is designed to be fully-functional for SWAT teams, but not look overly militaristic. The ensemble boasts over 30 pockets, with 25 in the pants and 8 in the shirt.

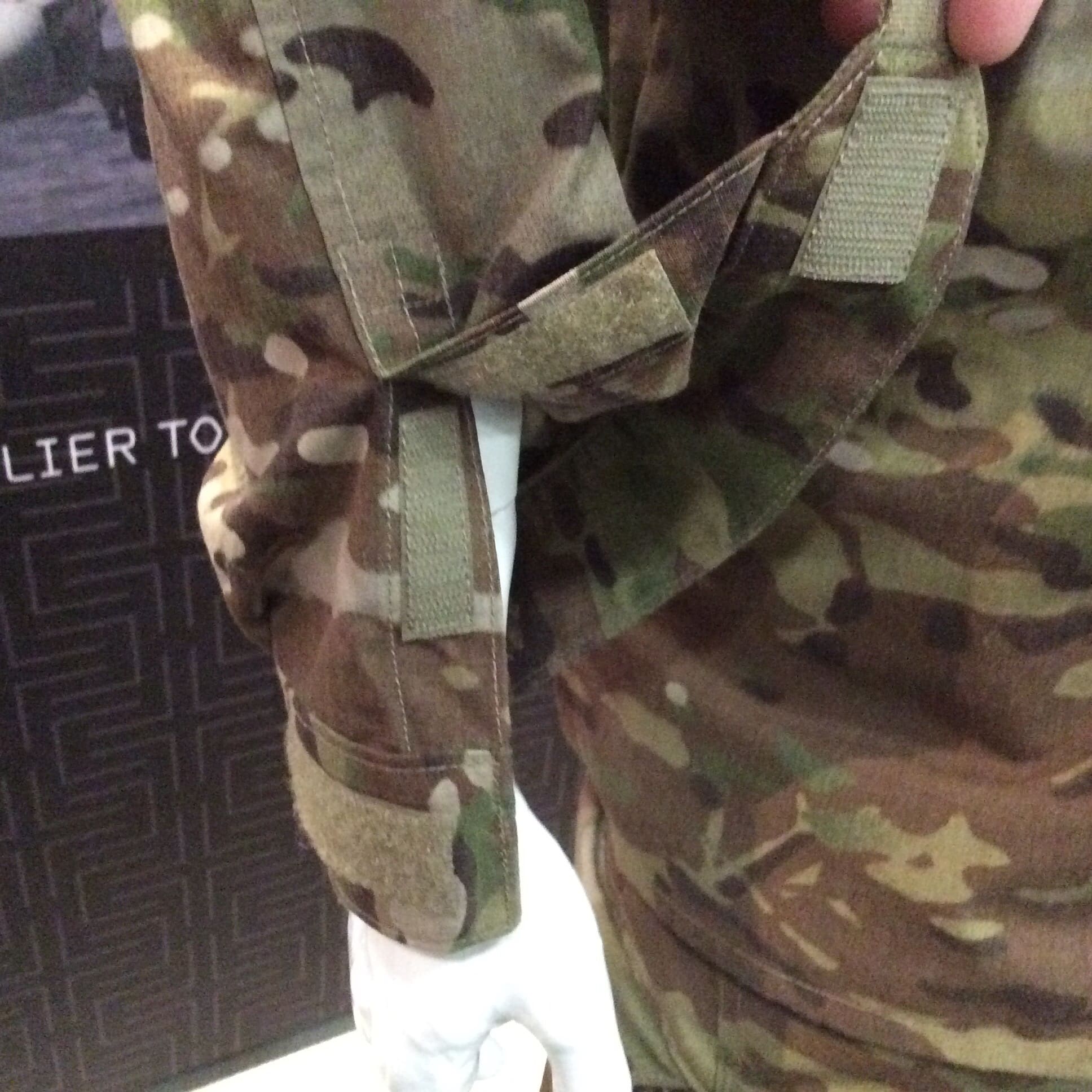

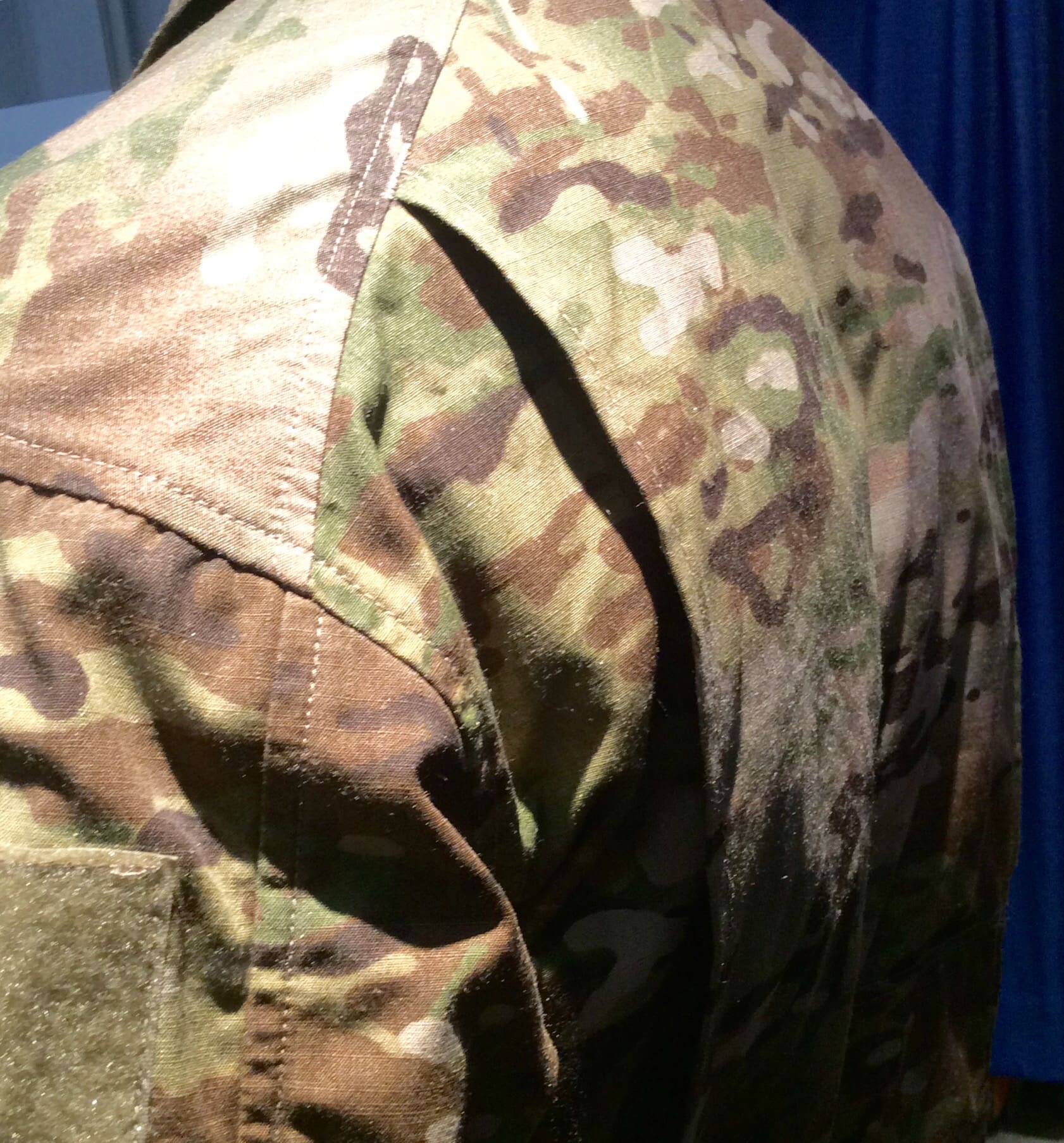

The Defender Shirt is a Combat-style. It’s made with a 6.5 oz, 100% polyester jersey body, offering snag and wrinkle resistance with moisture wicking fibers and an anti-microbial finish. The Sleeves and Collar are made from the 6.9 oz DuPont NYCO fabric (45% Nylon/ 55% Cotton) mechanical 2-way stretch micro double ripstop with moisture wicking finish. This material in the collar offers a stretch panel. Interestingly, they used a different fabric for the Side Panels. It’s a 4-way stretch (85% nylon/15% spandex)that won’t snag with moisture wicking properties and an anti-microbial finish. ??

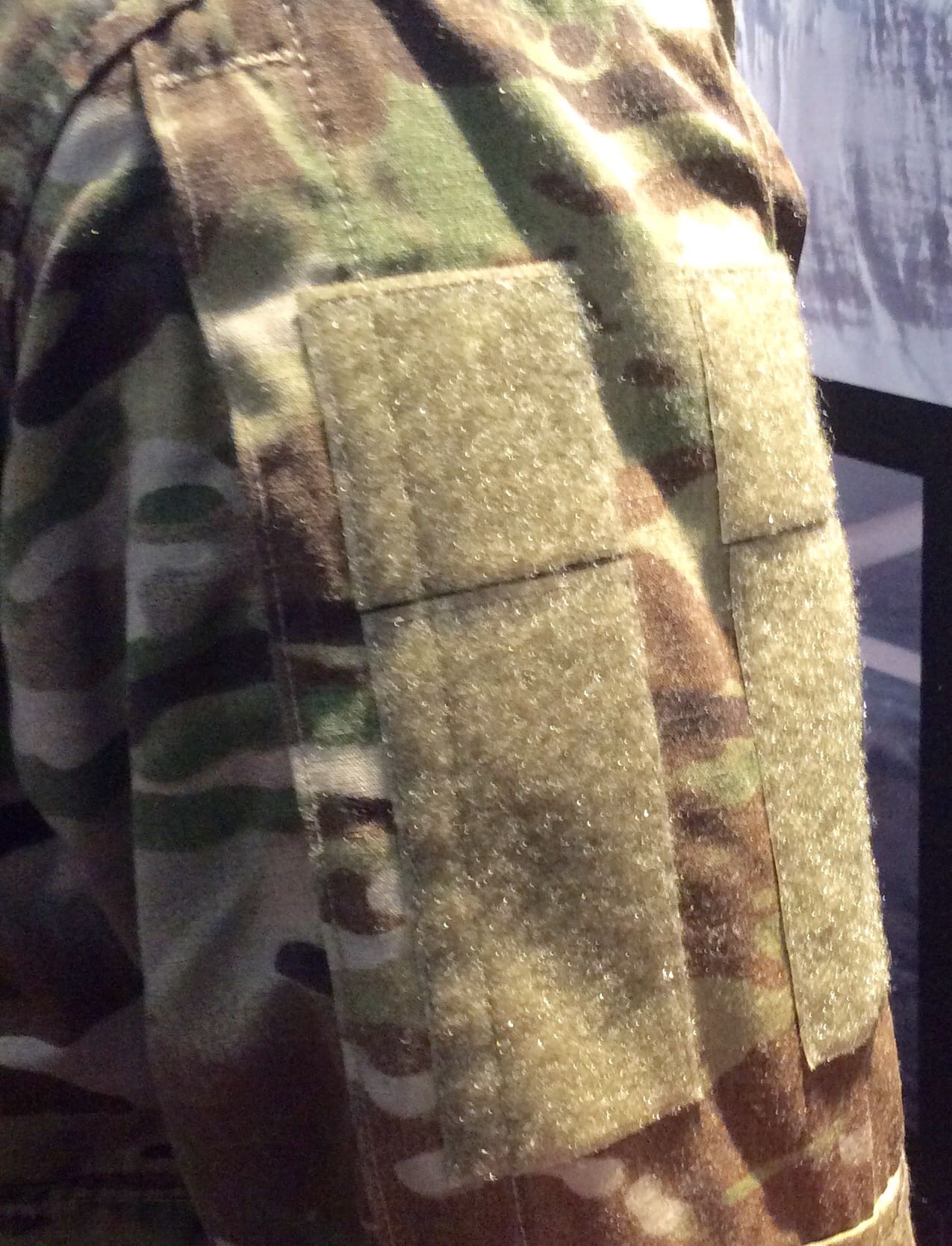

The Defender Shirt has a 1/4 zip front with professional fold-down collar and a yoke with off shoulder seams for a comfortable load/carry. The zippered sleeve pockets incorporate Velcro panels and a pen holder. The Elbow Patches FT Elbow Pads and the Sleeves are finished off with rollable cuff. ?

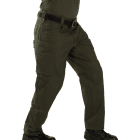

The Defender Pants are made from the 6.9 oz (55% Cotton, 45% Cordura® Nylon) mechanical 2-way stretch double ripstop, with moisture wicking finish.

Design features include welded reinforced knees with zippered side access for FT Defender Knee Pad integration, Comfort Flex Action Waist, riveted reinforced belt loops, nylon reinforced mesh pocket bags, knife clip protection pocket to prevent snagging, zip secure cargo pocket with internal organization which will accept up to 3 pistol mags, running gusset with articulation at the knees for maximum movement, and lower secure leg pocket.