FORT RILEY, Kan. – The Army supply chain of the future will incorporate additive manufacturing (AM), most commonly found in the form of 3D printing, to increase readiness. Using this technology at the point of need will reduce costs and increase unit mission capability.

The U.S. Army Ordnance Corps is in an excellent position to embrace this emerging technology, and ultimately, enhance Army lethality by developing Soldier expertise to support additive manufacturing programs.

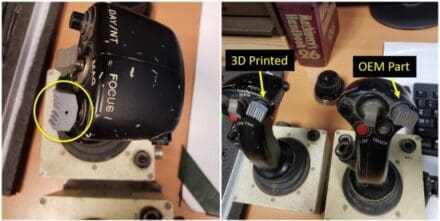

Under the Combat Capabilities Development Command, the Expeditionary Lab of the U.S. Army’s Rapid Equipping Force, or Ex Lab for short, operated 3D printers in deployed environments for nearly ten years, expediting the repair of equipment in combat areas.

In 2019, the Army established the Additive Manufacturing Center of Excellence as a hub for developing processes and standards to field additive manufacturing capabilities across the Army supply chain. The Army also invested in developing the materials needed to support future requirements and overcome current limitations.

Scientists at the ARL are working to develop filaments that are mechanically strong but useable in low-cost 3D printers. Using a combination of plastic polymers in a unique geometry, the ARL hopes to allow printing for a wider range of parts with samples scheduled for distribution and testing in the near future.

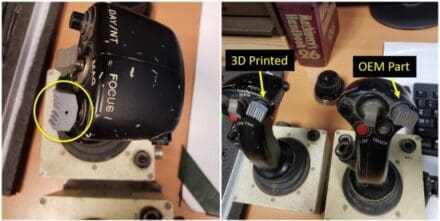

Field results are promising, and demonstrate maintenance units in the future will be able to make repairs in hours, develop custom solutions to complex problems, or reduce the on-hand stock and logistical requirements to support an expeditionary fighting force.

AM exhibited limited success in creating hard to find parts, manufacturing parts for legacy systems, and at the small unit level, printing 3D aids for explosive ordnance disposal training.

In the future, the technology could be migrated to the tactical level with teams of engineers and Soldiers collaborating to produce designs allowing the manufacture of physical solutions near the point of need.

But what if the expertise to design and print parts was staged closer to the point of manufacture? Current Army programs rely on engineers’ and scientists’ expertise to be effective. Few studies have been done on how the processes being developed will translate at a larger scale in an austere environment.

Existing programs rely on connectivity between engineers and Soldiers who could be thousands of miles apart. This connectivity is far from guaranteed on future battlefields. Therefore, complex post-processing requirements or more in-depth material knowledge may be necessary to operate independently from industries’ existing infrastructure.

The Ordnance Corps has an opportunity to build Soldier expertise to support these future programs. However, the expertise required to perfect these processes and provide a rapid, flexible and reliable supply of parts to tomorrow’s front lines could quickly overwhelm a Soldier’s current ability to take on additional training and tasks.

According to Col. Ken Letcher, former commander of the Joint Manufacturing and Technology Center at Rock Island Arsenal, “The Army is heavily invested in 3D printing, ensuring Soldiers have the capability to print and fabricate repair parts as a component of the Battlefield Damage Assessment and Repair (BDAR) process.”

As the current director of CASCOM’s Fielded Force Integration Directorate, Letcher noted that “Printing at the point of need increases operational readiness. Not only must the Ordnance Corps advance its materiel solutions, but it must advance the Soldiers that apply these solutions as they are fielded.”

By focusing on additive manufacturing as a specialty, Soldiers could receive training in computer-aided design software and materials science, allowing them to develop new parts and solutions independently from the industry support the Army currently relies on and move the point of design nearer to the end-user.

The Additive Manufacturing Specialists could be trained in various technologies, allowing future Army initiatives to leverage more specialized manufacturing techniques such as powder bed fusion, vat polymerization and bio-printing.

Teams of these newly created experts could also see expansion into a variety of Army missions beyond logistics. In 2018, the Marine Corps began experimenting with printing in concrete to rapidly build barracks in a combat environment with possible future applications in force protection, base infrastructure, and the support of humanitarian and disaster relief missions.

A joint study between the Geneva Foundation and the U.S. Military Academy saw success in bio-printing in austere environments, allowing treatments customized to the Soldier near the point of injury. As the technology expands across the Army, the need for professionals to advise and assist in its application will only increase.

Throughout history, the Ordnance Corps has developed cutting-edge professionals to build and preserve Army readiness. Currently the Allied Trades Warrant Officer (914A) serves as the Army’s AM expert. However, creating an Ordnance enlisted specialty to complement the rapidly expanding use of additive manufacturing would keep the Army at the forefront of innovation.

Integrating this technology into the Army structure and doctrine will allow the maximum flexibility in using new and emerging technologies as they transcend from laboratories to battlefields of the future.

By 1LT Joshua S. Closson