The folks at Program Manager-Special Operations Forces Survival, Support & Equipment Systems (PM-SOF SSES) office at the U.S. Army Soldier Research Development, and Engineering Center, Natick, MA have been pretty busy. Recently, they issued RFIs for Snow camo and Overwhite garments. Now, they are seeking FR combat uniforms for test and evaluation purposes as well as the the fabric that the garment is made from.

PCU level 9 Photo – US Army SFC Keith Turner

This is a pretty interesting Sources Sought Notice on a variety of levels. First off, with one exception SOF have not been using FR uniforms. MARSOC has been purchasing FR combat uniforms in Woodland camouflage from several sources for the past few years. Second, they already have an approved combat uniform that was developed specifically for their use and that the PCU Level 9. Finally, Natick has tested virtually every FR uniform fabric available. In fact, the results of that testing is available in the same building as PM-SOF SESS.

The desired characteristics in this RFI are generic at best and you can see those quoted below. If the desire is to field an FR combat uniform for SOF that can be accomplished in one of three fashions with little to no risk.

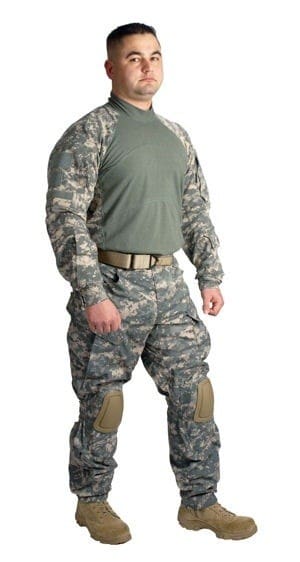

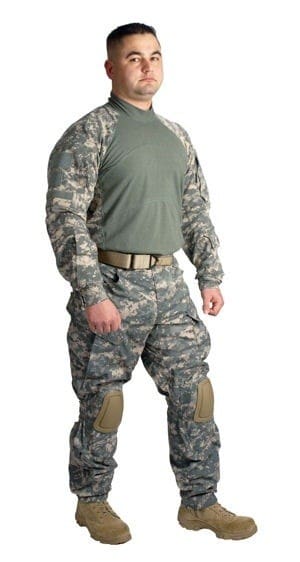

Both the US Army and Marine Corps already field FR combat uniforms in the form of the Army Combat Shirt and newly developed Army Combat Pant and the Marines field the Fire Resistant Operational Gear ensemble. Another option, if neither of those garments meet SOF requirements is, to take the approved PCU level 9 uniform and manufacture it from one of the myriad of FR fabrics currently available.

SOCOM is seeking:

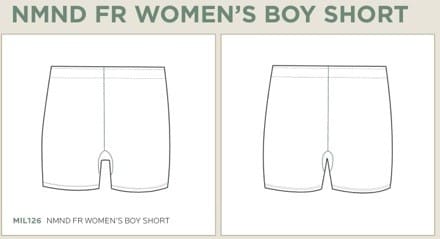

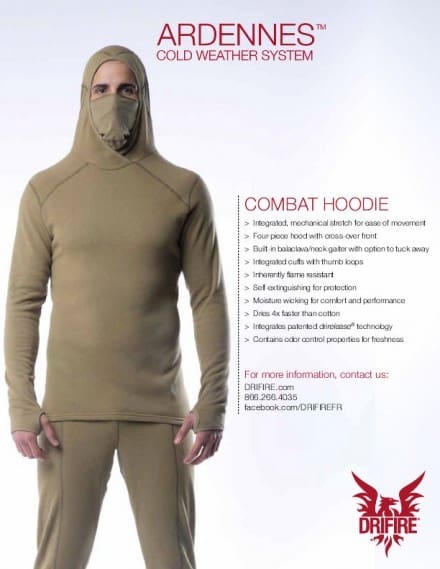

This uniform will consist of two garments; pants and combat shirt. Both will be produced with materials which provide fire resistant performance characteristics. The design and material performance characteristics are detailed below. All garments submitted to this solicitation will be reviewed and evaluated for operational efficacy. This uniform is intended for use by USSOCOM Operators, and as such must be effective in all operational environments, and be compatible with all Operator equipment.

Design characteristics:

Pants

* Sized in 2-inch waist increments

* Two front hand pockets

* Two back pockets

* Two large pleated cargo pockets

* Mechanism at lower leg hem to allow for fit adjustments of pants legs

Combat Shirt

* Collar, shoulders and sleeves shall be the same material as the pants and blouse

* Torso shall be a lightweight, moisture-wicking material

* length zipper across the center front

* Two upper sleeve pockets

* Sleeves shall have adjustable tabs at the wrists

Material physical performance:

In addition to the physical performance, any material submitted must be capable of being produced in military camouflage patterns and meet associated near-infrared requirements.

Interested companies are asked to submit one sample of the each garment, pants and combat shirt, in order to demonstrate the design. These samples must be produced in the material that is being submitted. In addition to the sample garments, please include 3 yards of the material to be utilized for physical performance testing, as well as a report showing any test results already obtained for the material. Pricing and size range for each garment should also be provided. Submissions must be received by 16 May 2013. Each company is authorized only one design and one material submission.

Currently, there are only two manufacturers that offer both their own FR fabrics as well as finished goods made from that fabric so this is a pretty curious RFI. Everyone else will be offering combat uniforms in someone else’s fabric. So the question is, what are they actually looking for? Garment designs or FR fabric solutions? Government solutions for both are readily available. Granted, a true FR solution must combine garment design with FR materials to ensure it provides ample coverage but generally, this involves tweaking of an existing garment once an FR fabric is selected.

Manufacturing these garments may well not be an option as SOCOM’s approved requirement for environmental and combat clothing is PCU and it must be manufactured by a directed source; NISH.

Perhaps this is the team’s answer to not being able to interact with industry at trade shows due to budget cutbacks and it will allow them to see the latest and greatest. Or worse yet, maybe its an unlikely case that they can’t afford to manufacture samples and it’s their way of soliciting free test samples. Although, they do say that they will buy additional garments from respondents who have a concept the Government wants to examine further.

As with all Sources Sought Notices, industry will provide their sample garment, sample fabric and proposal/pricing on their own dime. With the current state of industry (and government procurement dollars) everyone has to ask themselves whether the money expended to answer these RFIs is a good risk. Is there a real possibility of a pay off?

For those who are interested, find the Sources Sought Notice along with specific information on the FR performance specs at www.FBO.gov