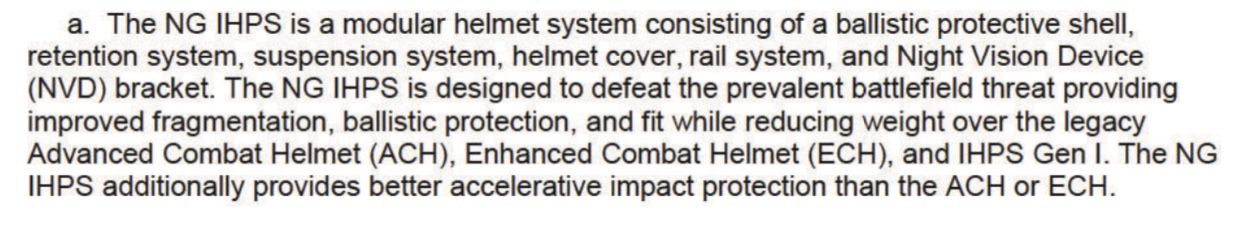

ArmorSource to offer new SKYDEX Iso-Fit Helmet Protection System to Military Troops and Law Enforcement as latest innovation to improve operational effectiveness

DENVER, COLO. (Sept. 8, 2021) – SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has partnered with ArmorSource to enhance the company’s combat helmets with state-of-the-art technology and a new generation of protection with the SKYDEX IsoFit Helmet Protection System.

A strategic move that will revolutionize the tactical helmet industry, SKYDEX and ArmorSource will combine forces to bring their best-in-class solutions and technologies together to create a helmet that features a custom fit liner and unbeatable protection for military and law enforcement communities. As a leading manufacturer of tactical helmets, ArmorSource is well equipped to leverage the new SKYDEX IsoFit system and lead the next generation of helmet protection.

“SKYDEX is proud to partner with a like-minded company that shares a similar standard of excellence and purpose to create solutions that protect people,” said Alvaro Vaselli, President and CEO of SKYDEX. “Between the recent advancements that ArmorSource has made with its helmet shell technology and our innovations in designing an unrivaled fit and impact protection, our solutions will help reshape the future of helmet protection on a global scale.”

The SKYDEX IsoFit Helmet Protection System features superior impact protection with an industry-leading energy-absorption pad system that can be easily integrated into any tactical helmet. With a patented micro-adjustment system, the IsoFit liner provides a customized fit and unmatched helmet stability to minimize distractions while users are in action. An added benefit includes open-airflow, designed to keep heads cool and dry in hot environments, combined with superior protection and fit. All of these elements offer users a safer and more comfortable experience, improving operational effectiveness.

“As a leading manufacturer of helmets, our mission is rooted in improving the survivability of military troops and law enforcement officers and ensuring our products represent the latest innovations for protection,” said Brad Grunden, President at ArmorSource. “By teaming up with the design experts at SKYDEX, we’re confident that this unique collaboration will elevate our company’s ability to leverage the most advance technology for military and law enforcement organizations and help grow the business substantially.”

To learn more about the new SKYDEX IsoFit Helmet Protection System available fall 2021, please visit www.skydex.com/product/skydex-isofit-helmet-protection-system.