Archive for the ‘Helmets’ Category

Visit Gentex at WEPTAC and SHOT Show

Tuesday, January 5th, 2016Australian Defence Force Selects Team Wendy Exfil Ballistic Helmet

Friday, December 18th, 2015Tiered Combat Helmet Contract awarded to Aquaterro APS

CLEVELAND – Team Wendy announces that its EXFIL Ballistic Helmet has been selected by the Australian Defence Force (ADF) as Tiered Combat Helmet (TCH) of record (Tiers 2 and 3) for the Soldier Combat Ensemble (SCE). The five-year contract with two additional 2 year options was awarded to Team Wendy’s partner in Australia, Aquaterro APS.

The EXFIL Ballistic is the third model in the Team Wendy EXFIL line, following two popular non-ballistic tactical bump helmets: Carbon (released in 2012) and LTP (Lightweight Tactical Polymer, released in 2013).

With a complete helmet system weight of 2.6 lbs. for Size 1 and 2.75 lbs. for Size 2, boltless CAM FIT retention with Boa closure system for optimized stability and fit, cam-lock sliders for positive locking adjustment, and a customized Zorbium impact liner with 2 full sets of comfort pads, the EXFIL Ballistic is designed to be comfortable during extended use all the while providing leading edge ballistic protection.

“We are thrilled that the ADF has selected the EXFIL Ballistic as their Tier 2 and Tier 3 program of record helmet. We also appreciate the confidence that the ADF has placed in Team Wendy and our partner in Australia, Aquaterro” said Team Wendy CEO Jose Rizo-Patron. “Since launching our EXFIL helmet program 3 years ago, we have worked hard to not only put out some of the most advanced helmet systems in the world, but to also provide our valued customers with industry leading service and support.” Rizo-Patron continued, “Team Wendy also recognizes the importance of working with industry leading strategic partners. To this end, we are pleased to highlight the support of our partners that are associated with the EXFIL Ballistic Helmet – ArmorSource LLC, Wilcox Industries and Boa Technology Inc.”

Morgan Advanced Materials Launches Ultra-Lightweight Hybrid Composite Military Helmet Range

Monday, December 14th, 2015Morgan Advanced Materials, a world leader in the application of advanced composite material technology, has unveiled its newest range of lightweight combat helmets, the LASA AC914 and AC915.

The LASA AC914 and LASA AC915 draw upon the expertise of the Composite and Defence business of Morgan Advanced Materials. Morgan has a wealth of experience in composite materials and an established pedigree within the military and law enforcement sectors, having sold in excess of one million helmets worldwide. The helmets’ revolutionary designs deliver outstanding ballistic performance and comfort to the wearer. Made using a hybrid of composite materials and incorporating Morgan’s proprietary technology, the helmets’ shells are approximately 30% lighter than previous generation technology and deliver outstanding protection against ballistic threats, fragments and blunt trauma.

In full compliance with NIJ 0101.06 level IIIA, the LASA AC914 and AC915 offer an unparalleled level of protection against blunt trauma and 9mm rounds, maximising user safety in combat situations. The high-cut LASA AC915 weighs little more than 1kg and allows for greater situational awareness, making it ideal for special operations. Similarly, the AC914, with its full-cut design for combat operations, offers unparalleled ballistic and blunt trauma protection – particularly impressive given that it weighs a mere 1.2kg (2.6lb). In both instances, the AC914 and AC915 offer exceptional levels of fragmentation protection and come with optional visor and mandible guard to provide greater high impact protection for the eyes and face.

Available in a variety of configurations, the LASA AC914 and AC915 are compatible with in-service equipment including night vision goggles as well as an array of other accessories. While the helmets have been designed to offer the greatest levels of protection, the configurable suspension systems also deliver optimum levels of user comfort.

Duncan Eldridge, President of Morgan Advanced Materials – Composites and Defence Systems, explained: “we are delighted to launch the LASA AC915 and AC914 helmets, the helmets are a result of three years of materials and product development, which have also been applied to our next generation helmet for Canada. Our expert knowledge in composite materials and application has once again allowed us to create a range of helmets that offer a level of protection at a weight beyond that typically afforded by standard ultra-lightweight helmet solutions.

For further information please visit Morgan Advanced Materials – LASA Soldier Systems

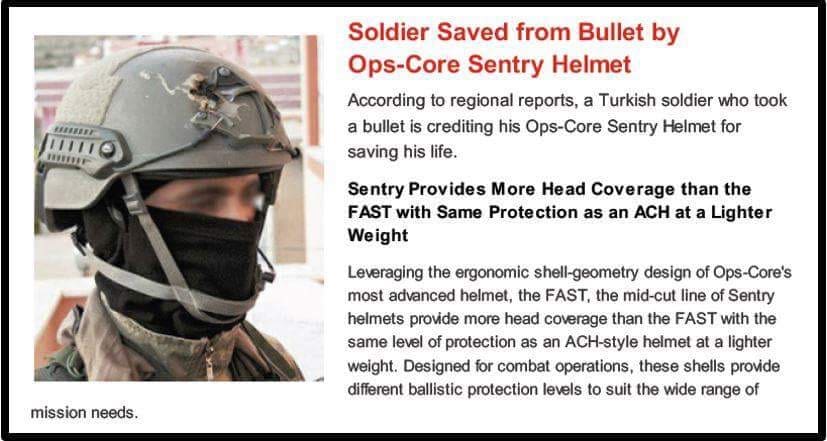

Ops-Core Helmet Saves Turkish Soldier’s Life

Thursday, December 10th, 2015Spiritus Systems – Lid Snake

Thursday, December 3rd, 2015The Lid Snake is designed to protect your night vision cables that lead from a rear mounted battery pack up to the mount which is great for guys who don’t use a cover.

Berry Compliant, the Snake Lid is constructed from Genuine 330D (MultiCam) and 500D (All other colors) Cordura in MultiCam, MC Arid, MC Tropic, and MC Alpine.

www.spiritussystems.com/new-products-1/helmet-snake

Unity Tactical – KNUCKL Helmet Mount

Tuesday, December 1st, 2015Unity Tactical’s KNUCKL is a modular helmet accessory mount. Designed to mount to a helmet’s accessory rail, such as those on Ops Core, Team Wendy, and Crye helmets, the KNUCKL features tension-adjustable 3-axis articulation, and allows for the mounting of up to two accessories. The KNUCKL also incorporates a socket for the Wilcox Retention Lanyard, which retains gear during a break-away.

Available in Black and FDE.

www.unitytactical.com/product-category/knuckl-helmet-mount

Team Wendy Cyber Monday Sale

Monday, November 30th, 2015Milipol – Gallet Accessory Rail Combat Helmet

Tuesday, November 24th, 2015I took a few shots of the Gallet Accessory Rail Combat Helmet originally released at Milipol 2013. The designations are official designations of this line of helmets are the Gallet TC 800 series and Gallet TC 500 series. Some readers may not know this but the MICH was originally a Gallet design and the French company was purchased by MSA.

The rails feature proprietary 360° rotating buckles on the front and lower back (three slots on each rail). Additionally, the removable “V” shaped, ratchet-style shroud clamps under the front brim of the shell, and bolts unto each of the upper portions of the side rails in the back. On top of the actual NVG interface (USGI/Wilcox compatible), between the two “V” branches, they’ve added bungee ties that go all the way to the top, in order to secure strobes and other non-railed accessories.

In these photos you can see how the oxygen mask attaches to the rail. The Minie Night Vision Device is from Thales Angenieux.

Specifically, the helmet models are 800/801/802 (first digit is shell thickness in millimeters, last is cut style), the fourth model released is the 501 (same naming convention applies). The 501 is the thinnest Gallet helmet available that still retains a frag rating. Interestingly, there is only one shell size and different head sizes are accommodated via pads.

The line of ARCH is offered in NATO Green, Black, Tan.