LENGGRIES, GERMANY (15.05.2025)

In a recent interview, Jakob Kolbeck, Managing Director of Lindnerhof, takes us behind the scenes of how the unique and often extreme demands of military, police, and special forces operators directly influence the company’s cutting-edge product development. With a deep understanding of operator needs, Kolbeck reveals how Lindnerhof’s commitment to performance, innovation, and adaptability is pushing the boundaries of tactical gear, ensuring that every solution not only meets but anticipates the challenges faced by elite military and law enforcement units worldwide.

Q: How has your background in special operations influenced your leadership style at Lindnerhof and the way the company operates? Can you share an example of a product inspired by that experience?

A: My career in special operations taught me to adapt quickly and respond decisively. The mindset of “plan – do – check – act” is deeply ingrained in how I operate—it became second nature during my time in the field. At Lindnerhof, that approach translates into a continuous cycle of improvement and adaptation, especially since we work so closely with Special Operations Community. We’re not just designing products—we’re actively solving problems that operators face in the field.

One concrete example is our tactical climbing harnesses. These products were directly shaped by my own operational background, combining my experience as a SOF operator and a military mountain guide. The knowledge I gained in real-world scenarios influenced both the design and functionality of our current models.

Q: How does Lindnerhof maintain its edge in design compared to others in the industry?

A: We operate with a simple but critical design philosophy: functionality first. That means we never compromise on tactical requirements to make a product more commercially appealing or comfortable at the expense of performance. For example, we wouldn’t add padding to a plate carrier that might make it more comfortable but hinders a proper shoulder weld with a rifle stock. Every feature we integrate must serve a purpose in real-world operations.

Innovation at Lindnerhof is tightly linked to practicality. We don’t chase innovation for its own sake—we innovate to solve real problems or improve functionality. In many cases, that pursuit of functionality leads to innovation as a natural outcome.

Q: How do military and law enforcement needs influence your product development?

A: Our development is fully driven by the requirements of military and law enforcement professionals. We never design products solely for the commercial retail market. Any item we offer to civilians is essentially a version of something we first developed based on the operational demands of professional users.

Q: How does field experience influence the development of Lindnerhof products?

A: Field experience shapes everything—especially when it comes to durability and usability. A product must be intuitive to handle and robust enough to withstand extreme conditions. We avoid unnecessary “fancy” features that serve no purpose in the field. Every person involved in our development process—from designers to seamstresses—understands that lives may depend on what we build.

Q: How do you balance durability, weight, and adaptability in product design?

A: We start by defining what a product must do—what the operational requirements are. Take our ultralight plate carrier as an example: we didn’t begin by chasing a weight goal. We designed it to meet performance needs, and it turned out to be one of the lightest plate carriers available. If we had prioritized weight alone, we might have compromised durability. Creating a lightweight product isn’t just about trimming grams—it’s about understanding where stress points are and how a product will actually be used.

Q: How critical is operator feedback in the product development cycle?

A: Absolutely essential. We don’t pretend to have all the answers. Feedback from elite users allows us to refine and improve our gear. Without their input, we’d risk falling short of what real-world scenarios demand.

Q: How does Lindnerhof stay ahead in material and ergonomic design?

A: We don’t just buy raw materials—we work with material manufacturers to improve them. That collaboration has led to the development of three custom laminates made exclusively for us. These materials are tailored to our operational needs and are very different from commercial off-the-shelf options.

When it comes to ergonomic design, the military and law enforcement context is unique. Ergonomics isn’t just about fitting the human body—it’s about optimizing the interaction between the operator and their equipment. For example, a shoulder strap may not seem ergonomic by itself, but when you factor in the way it works with the buttstock of a rifle, that’s where true ergonomics come into play.

Q: How does Lindnerhof adapt to evolving mission needs and changes in tactical doctrine?

A: We already have a wide range of products that cover most needs. But when TTPs (tactics, techniques, and procedures) shift or when military conflicts evolve—as we’ve seen in Ukraine—it creates new requirements. In these cases, we conduct thorough analyses, including interviews with operational experts, and translate those findings into new designs. One such innovation is currently in development, driven entirely by recent combat requirements. I can’t share details yet, but it’s something that didn’t exist before.

Q: Where is the industry headed in terms of modularity and weight optimization—and how are you preparing for it?

A: Weight reduction is a tricky subject because cutting those last grams often comes at a very high cost. It’s no different than in the cycling industry: shaving 100 grams off your racing bike means investing in ultra-high-end components. That same logic applies here. We always need to balance performance with affordability.

Modularity, however, has always been central to our philosophy. It allows operators to configure their gear to their exact needs. We’ll continue building on that principle because it’s what the field demands—and the entire industry is moving in the same direction.

Q: How does Lindnerhof collaborate with other brands in the Mehler Systems Group to drive innovation?

A: When you look at integrated systems like a plate carrier paired with a battle belt, there are obvious interfaces with ballistic protection and apparel. Within the Mehler Systems Group, we work closely with the other brands—particularly in ballistics—to not just improve protection levels, but also to increase the protected surface area of the body.

Q: The M.U.S.T. system is one example of that collaboration. Can you tell us more?

A: That system was developed in response to real incidents where operators were fatally wounded in areas not covered by traditional plates. We analyzed the root causes and proposed improvements. Mehler Protection developed ballistic plates to cover lateral areas of the upper body and thighs, while Lindnerhof contributed insights on usability and tested the prototypes. The result—M.U.S.T.—is a fully integrated system that harmonizes modular textile components with advanced ballistic protection. It’s a great example of what we can achieve when we work together across disciplines.

Q: How does cross-functional teamwork support Lindnerhof’s development goals?

We now have dedicated Group Directors overseeing key areas, including Innovation and Technology. That person has a full view of what’s happening across all companies in the group and helps coordinate efforts, align roadmaps, and make sure we’re not duplicating work but building on each other’s strengths.

Q: What tactical trends are shaping Lindnerhof’s current R&D efforts?

A: The war in Ukraine has reshaped a lot of priorities. Military organizations across Europe are shifting from expeditionary warfare to homeland defense, and that changes what’s needed on the ground. Products that made sense in Afghanistan aren’t necessarily the right fit now.

At the same time, law enforcement is facing increasing challenges—active shooter incidents, for example. That’s why we’re now developing modular protection systems tailored specifically to police forces. We’re not just reacting—we’re actively anticipating these needs.

Q: How is Lindnerhof preparing to meet the future needs of special operations forces?

A: We believe our position is already strong. Our close connection with operators on the ground and our modular approach to design mean we’re well prepared to meet future requirements without needing to pivot dramatically. We’re built for adaptability.

Q: Are there any upcoming innovations you’re particularly excited about?

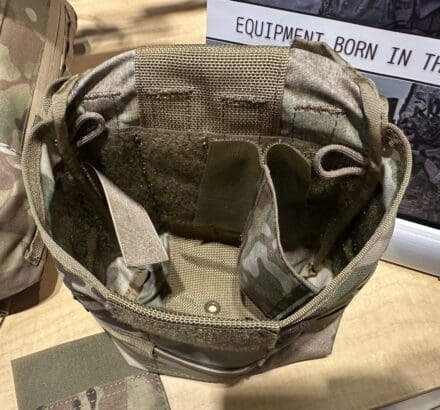

A: Yes, we currently have three new carrying solutions in development. I believe each of them will significantly enhance performance for both military and police operators. I’m genuinely excited about their potential to make a difference in the field.

About Jakob Kolbeck:

Jakob Kolbeck is the Managing Director of Lindnerhof, a role he has held since April 2018. With a career spanning over two decades, Kolbeck has extensive experience in sales and management within the defence and security sector.

Before joining Lindnerhof, he served as Senior Manager Sales at RUAG Ammotec GmbH and Director Marketing & Sales at Unique Alpine AG. His career also includes significant roles in the military, including project leadership and operations planning.

Kolbeck holds a Master of Business Administration in International Management and a degree in State and Social Sciences, complementing his robust technical and commercial background.

Under his leadership, Lindnerhof is advancing its specialised tactical gear solutions, driving innovation and growth in the industry.