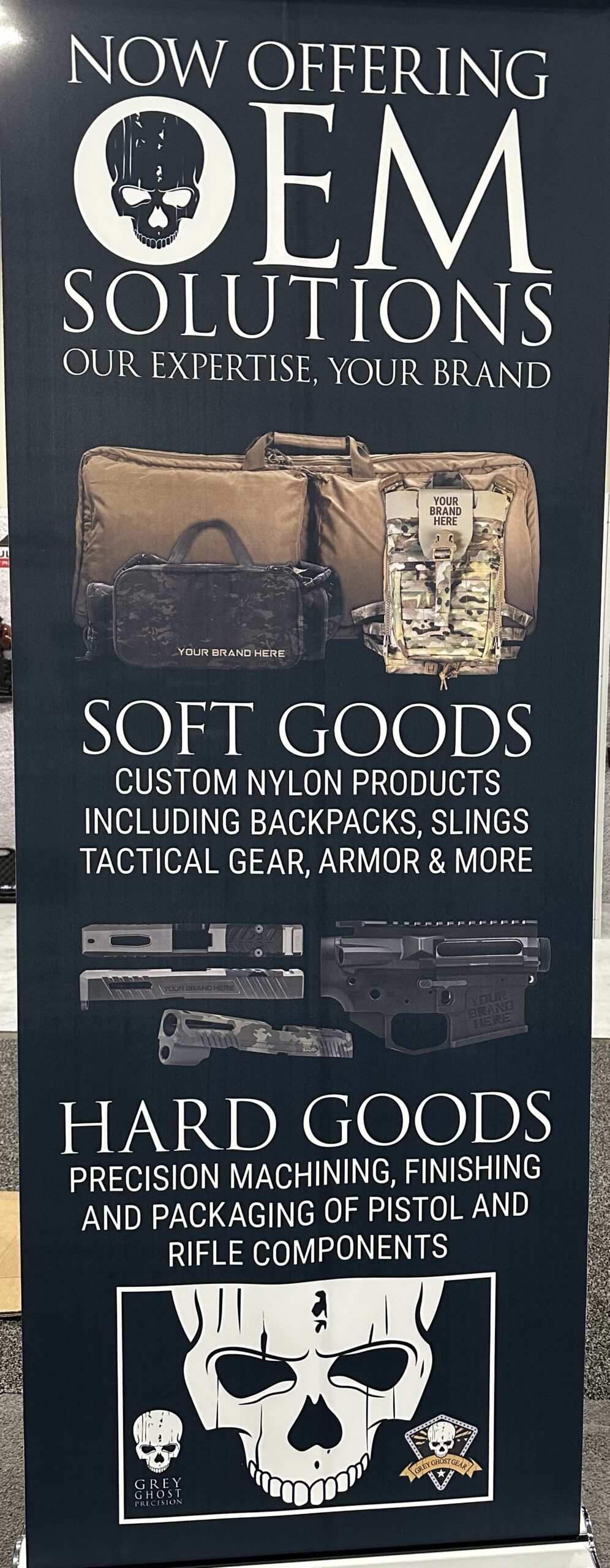

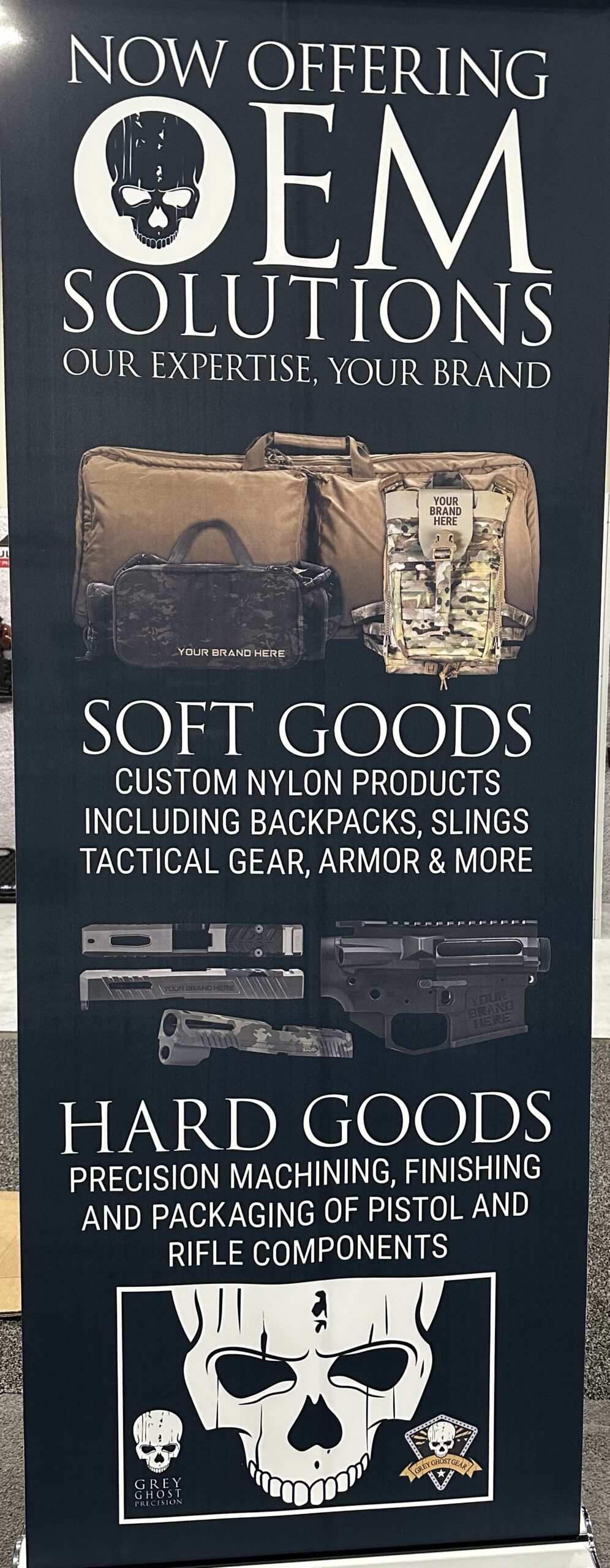

Grey Ghost Gear and Grey Ghost Precision have announced that they offer OEM services for both soft and hard goods.

Whether you need nylon goods are firearms and accessories, give them a shout.

Grey Ghost Gear and Grey Ghost Precision have announced that they offer OEM services for both soft and hard goods.

Whether you need nylon goods are firearms and accessories, give them a shout.

Made from FR Phase 1 which is one of the lightest most durable FR fabrics on the market, the ling sleeved Lightweight Assaulter Shirt joins the short sleeved version already on the market.

The fabric also features Acclimate Dry Moisture Management to wick sweat away from the body and dry rapidly as well as AG47 Silver Anti-Microbial to fight and eliminate harmful bacteria from your sweat, leaving you odor free.

New Law Will Help Ensure Domestically Manufactured Uniforms and Equipment are provided to Department of Homeland Security Operational Personnel

MARBLEHEAD, Mass., Jan. 09, 2023 — The Warrior Protection and Readiness Coalition (WPRC) commends the inclusion of the “Homeland Procurement Reform Act” in the Fiscal Year 2023 National Defense Authorization Act, recently signed into law by President Joseph Biden. The HOPR Act is the culmination of several years of WPRC advocacy on behalf of the domestic industrial base and American companies that provide 100% made-in- America uniforms, footwear and protective equipment to the Federal government.

This critical, bi-partisan legislation ensures that the operational units within the Department of Homeland Security (DHS) including Customs and Border Protection (CBP), the Transportation Security Administration (TSA), U.S. Secret Service, and Immigration and Customs Enforcement (ICE) procure uniforms and equipment manufactured in the United States. Currently, many DHS agencies purchase uniforms and equipment manufactured in foreign countries that lack supply chain dependability and secure protocols for handling sensitive uniform items. The HOPR Act sets a new precedent to ensure that uniforms, footwear, body armor and equipment for DHS frontline personnel are built in the United States, supporting the industrial base and ensuring supply chain security.

On behalf of their 60+ member companies, the WPRC extends appreciation to primary sponsors Senator Jeanne Shaheen (D-NH), Senator Mike Rounds (R-SD), Rep. Lou Correa (D-CA), and Rep. Brian Mast (R-FL) as well as co-sponsors Sen. Maggie Hassan (D-NH), Sen. Jerry Moran (R-KS), Rep. Chris Pappas (D-NH), and Rep. Jim McGovern (D-MA). HOPR sponsors ensured that this critical legislation was maintained in the FY23 National Defense Authorization Act, and that DHS begins to move towards domestic sources of supply to meet current and future homeland security challenges.

The new law establishes specific criteria that increases the ability of DHS to obtain high-quality, American-made personal protective equipment (PPE) and organizational clothing and individual equipment (OCIE). The HOPR Act builds upon procurement laws such as the Berry Amendment and the Kissell Amendment by expanding opportunities for American manufacturers that meet specific, domestic manufacturing criteria.

WPRC Executive Director David Costello said, “Department of Homeland Security personnel as well as the American public owe a debt of gratitude to the members of Congress who have championed this important legislation. Thanks to their leadership, uniforms, armor, footwear and protective equipment needed by DHS personnel will be supplied by high-quality American sources, improving the quality and performance of this category of products while supporting American jobs. The WPRC looks forward to working with the DHS and the White House to encourage the rapid implementation of this domestic procurement policy.”

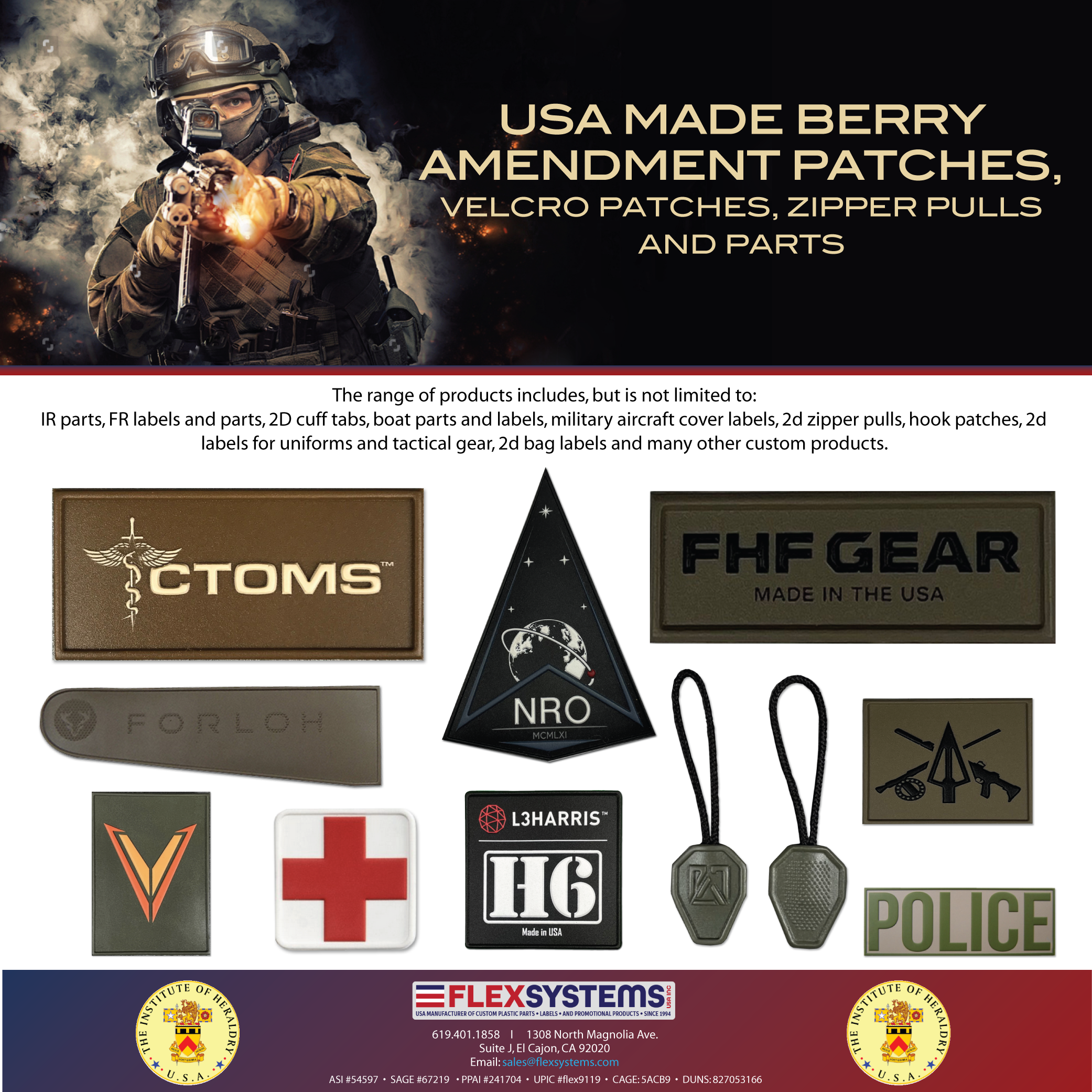

In addition to manufacturing the PVC morale patches we guve away at tradeshows, our friends at Flex Systems make other Berry Compliant items like tags and pulls.

flexsystems.com/custom-manufacturing/berry-amendment-parts-and-patches

True Velocity’s Special Patriot Edition includes 20 cartridges of .308 WIN loaded with 168-grain Nosler Custom Competition HPBT projectiles, and each cartridge is emblazoned with the American Flag!

Get yours at tvammostore.com/product/special-patriot-edition-308-win-nosler-hpbt.

1 July 2022

First Breach, Inc. expects to begin manufacturing match-grade components in July, 2022 at its approximately 75,000 sqf facility located in Hagerstown, Maryland, USA. All of First Breach’s components will be made in the USA. Component production will include brass cups, brass casings, full metal jacket (FMJ) projectiles, lead projectile cores, and lead wire. Lead and lead products are smelted from scratch in-house at First Breach’s facility. First Breach will offer its components in a variety of calibers and grains at e-commerce, retail, bulk wholesale, and OEM levels.

First Breach takes great pride in the quality of its US made components. Equipped with numerous quality control checks, First Breach will offer match-grade, SAAMI specification products bar none. Customers will have the ability to order custom head stamped casings as well as a wide range of grain size options for projectiles.

First Breach is happy to extend an invitation to tour our Maryland facility for qualified parties.

For sales & tour inquiries, please contact CJ Dugan, Senior VP of Business Development:

+1 (443) 901-6147

For investor relations, please contact Karl Brenza, CFO:

+1 (914) 374-0060

The LEGEND® Compression Wear Tactical Boot Sock program is proudly “Made In USA”; in North Carolina; is Berry Amendment Compliant, and part of the SKILCRAFT® Program “Supporting Jobs for Blind Workers”.

During the program development process, soldiers and warfighters were interviewed, listened too, and participated in on going wear test evaluations! The focus from the beginning was to provide needed, durable, comfortable, compression boot socks. During the evaluation process modifications were made; until the final development samples, received consistent highly recommended evaluations. The evaluation process did not stop there and ongoing evaluations continue to be performed by soldiers, warfighters, fire, wild fire, emergency and rescue workers.

The LEGEND® Compression boot sock program is user, function based consisting of three core compression boot sock styles. The LEGEND® Compression Merino Wool All Weather, Compression Merino Wool Cold Weather and the LEGEND® Compression Warm Weather Superior Moisture Wicking Micro Channel, Hydrophilic Nylon boot socks. In extreme or varying cold conditions, two styles can be layered trapping warm air between the layers for greater insulation.

To better serve the needs of our growing customer base we sought after and have received The Department Of The Air Force Certification as No Melt No Drip (NMND) Flame Resistant (FR) Safe to Fly (StF) for the LEGEND® Compression Cold Weather Merino Wool Boot Sock. Having met the criteria for this Certification we are in a position to provide greater safety to our flight, shipboard, special duty, deployed, fire and rescue, defenders and rescue workers.

Features that make a difference! If your feet are comfortable you can better execute your duties each day, all day, day after day.

• Mild Graduated Compression helps improve blood flow, reduce foot fatigue, achy feet, and recovery time.

• Seamless toe design, added support, and dense terry cushioning to reduce friction, toe irritation, and to increase comfort.

• Wide Arch Support to minimize sock movement, blisters, and provide greater comfort.

• The Cold Weather boot socks use a high percentage content of moisture wicking, temperature regulating, breathable, antibacterial, and odor resistant Merino Wool. Legend uses an innovative engineered Spuncover™ process; wrapping our merino wool in nylon, that makes our socks, softer, more durable, with minimal shrinkage.

• Knit with a dense terry cushioning through-out the entire sock to help keep your feet warm during cold weather conditions.

www.legendcompressiontactical.com

Proudly “Made in USA” Berry Compliant, SKILCRAFT® Program “Supporting Jobs for the Blind Workers”

Here’s a great replacement for that wimpy lug wrench that came with your vehicle.

forresttool.com/products/the-safety-impact-wrench