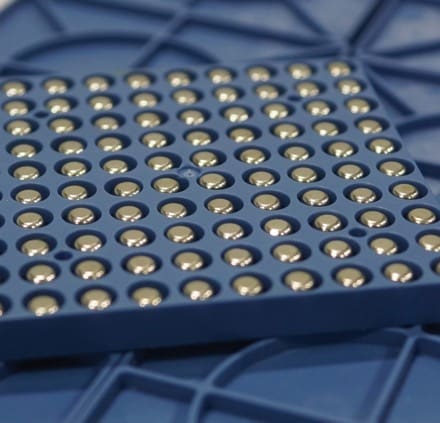

Blacksburg Virginia – 3rd October 2024: Delta Three Oscar, the ballistic arm of D3O renowned for its cutting-edge protective materials, has developed D3O® Ballistic, an advanced lightweight energy dissipating foam designed to support body armor manufacturers in meeting the new NIJ Standard 0101.07 and its new Back Face

Signature (BFS) requirements – the amount of deformation, or damage, created on the backside of a hard armor plate after a threat impact. This updated certification protocol, issued by the National Institute of Justice (NIJ), offers enhanced protection and revised testing procedures, making it a significant upgrade over the previous NIJ Standard 0101.06.

As body armor manufacturers redesign and retest their products to comply with these new requirements, D3O Ballistic has become an essential solution for maintaining critical BFS performance while optimizing wearer comfort and mobility. Ten renown global manufacturers, have already adopted D3O Ballistic for their next-generation body armor systems, highlighting the material’s broad industry appeal.

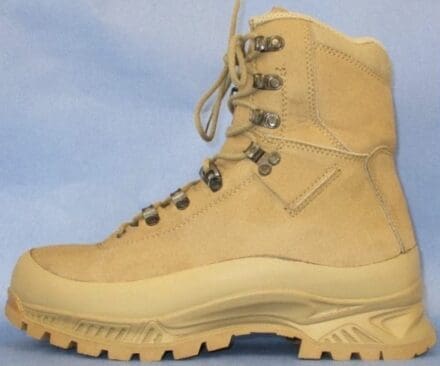

Lightweight, Low-Bulk, High Protection

D3O Ballistic has been meticulously engineered to reduce the armor BFS for a wide range of threats, while improving mobility and comfort. This groundbreaking foam provides a crucial layer of protection for front-line personnel, minimizing non-perforating hit trauma and maximizing chances of carrying on with the mission. By offering a low-weight and low-bulk solution, it ensures that NIJ-certified body armour solutions remain mobile, comfortable, and reliable, addressing a key challenge in protective gear development.

This development comes at a critical time as the updated NIJ Standard 0101.07 introduces tougher requirements and more complex testing protocols. With D3O Ballistic, brands can confidently pass the new NIJ plate certification while ensuring the highest levels of safety and mobility for users.

Revolutionizing Protection for High-Risk Environments

“Delta Three Oscar is committed to saving lives,” said Stuart Sawyer, Delta Three Oscar CEO. “Our goal is to revolutionize protective gear for those operating in high-risk environments, and our Ballistic foam is a key part of that mission. This material isn’t just about protection—it’s about comfort, mobility, and ensuring that those on the front line have the best possible chance of coming home safely.”

In addition to supporting the U.S. Department of Defense, Delta Three Oscar’s innovative materials are used by international defense and law enforcement organizations around the world. The company’s products are also Berry Amendment compliant, making them a trusted partner for U.S. military procurement.