Team Wendy Engineers Among Research Team Published in Military Medicine

CLEVELAND, OH (Sept. 30, 2021) – Engineers from Cleveland-based Team Wendy®, a leading global provider of exceptional head protection systems, led experiments for a study published earlier this month in Military Medicine that indicates a need to revise combat helmet specifications.

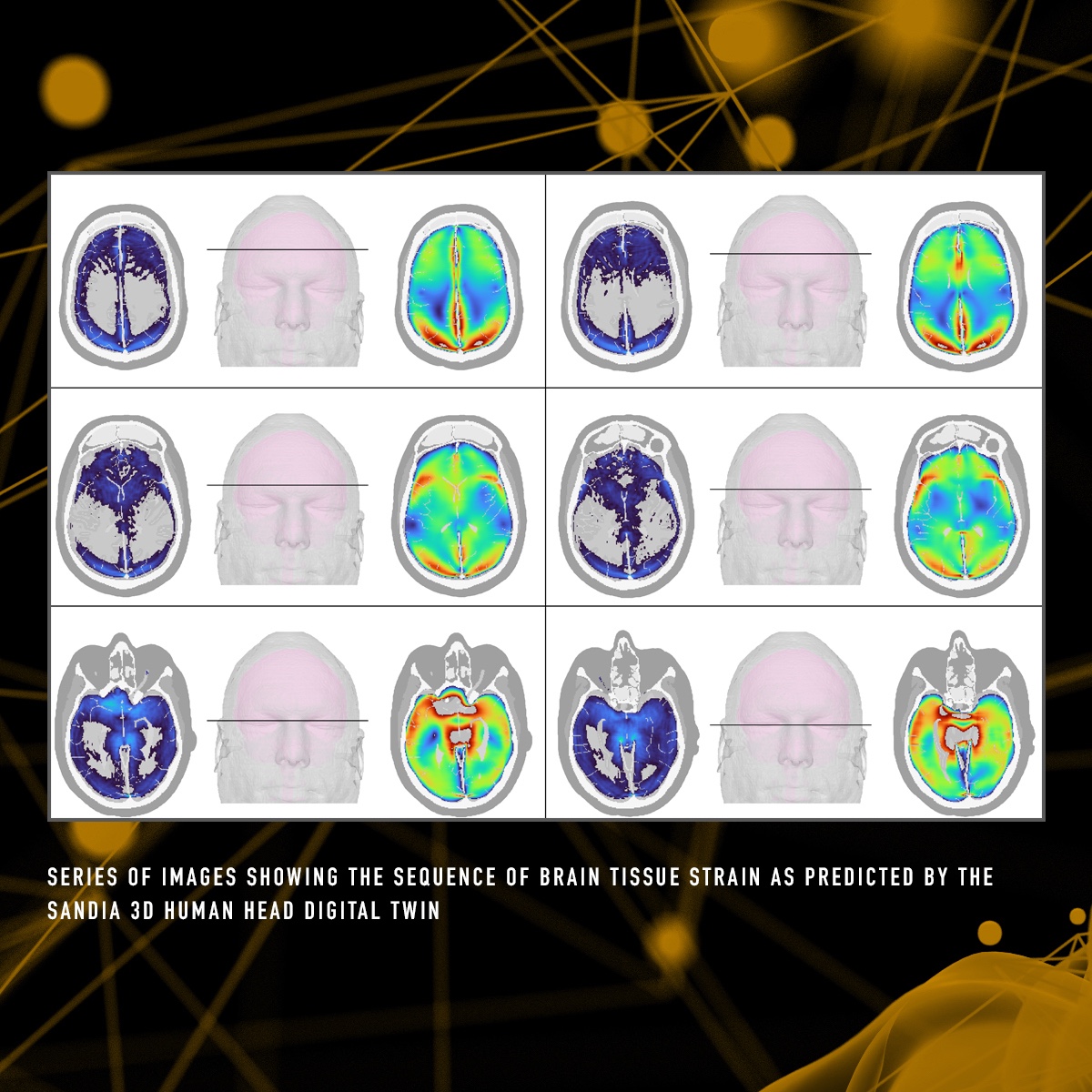

The paper, titled “Head Impact Modeling to Support a Rotational Combat Helmet Drop Test,” provides a scientific basis for combat helmet test requirements to include rotational impact tests in order to account for cellular injury thresholds. The additional data would improve the test’s conception of traumatic brain injury (TBI) caused by severe head impacts.

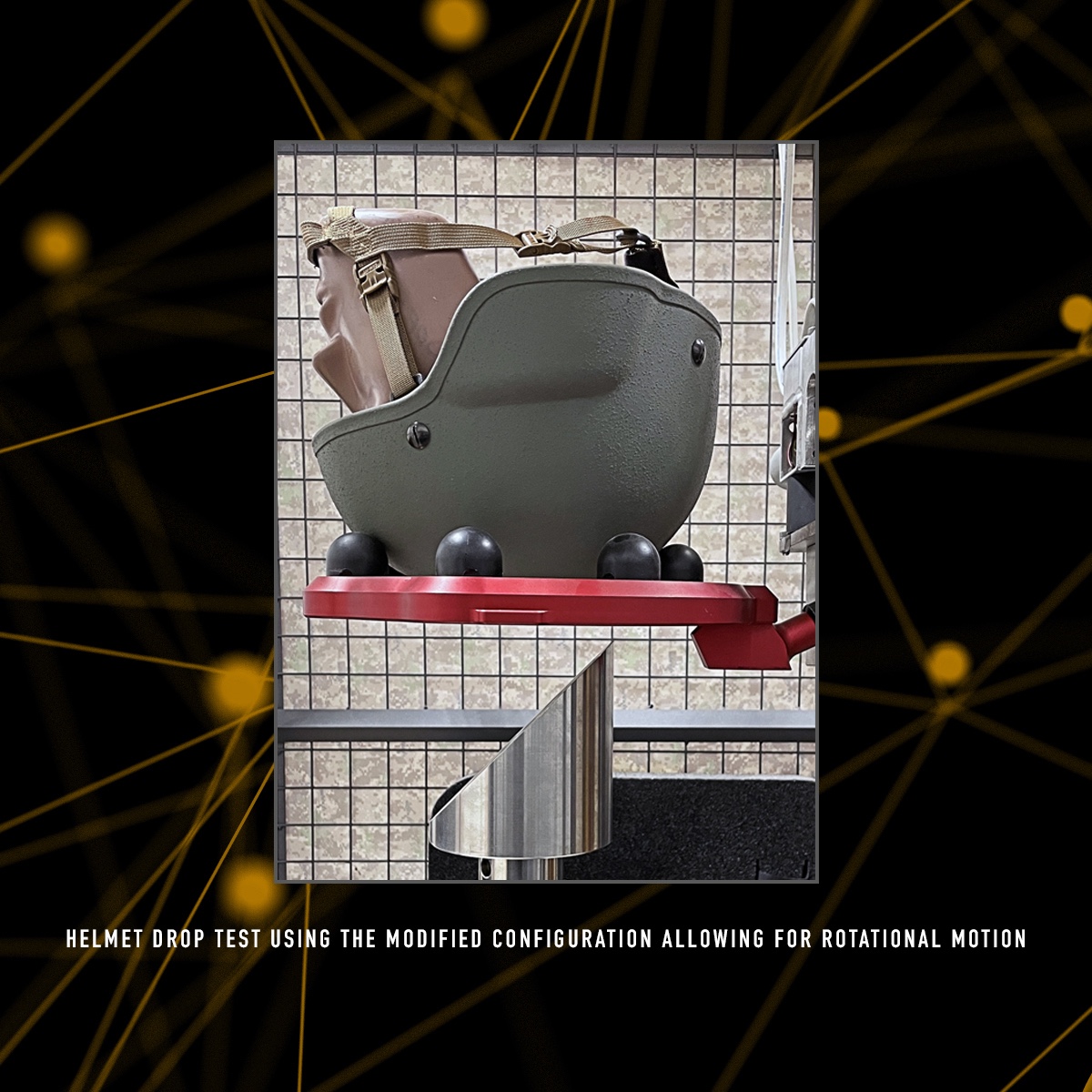

Currently, military combat helmets are evaluated by linear acceleration thresholds, which originated from skull fracture prediction. The study examined predicted brain cell damage in both linear and rotational impact scenarios to assess how much brain tissue stretches, and how quickly, upon collision.

“Real life impacts are rarely limited to translational motion, where the head decelerates in a straight line,” said Ron Szalkowski, one of the paper’s authors and Team Wendy’s director of product development and research collaboration. “Continuing to evaluate linear impact is important, but without also analyzing how the helmet and head respond to rotations, we could be missing a key piece of the puzzle in our ability to accurately predict TBI.”

In its exploration of cellular injury levels, the team found that linear tests do not fully convey the tissue stresses and strains indicated in rotational tests. Using a detailed human head model from Sandia National Laboratories, they discovered over four times the brain strains resulting from a modified rotational test versus the strains produced in the standard linear test.

The findings were published in the military medical journal with credit to researchers from Team Wendy, Sandia National Laboratories, Robert Morris University, Brown University and University of Wisconsin-Madison. Team Wendy Mechanical Engineer Sushant Malave is bylined alongside Szalkowski.

The study was part of phase one of the PANTHER program, a research partnership funded by the Office of Naval Research (ONR) with the goal of quantifying cellular injury levels for TBI.

“This paper reflects a stepping stone for further understanding the relationship between brain strains and head protection,” Szalkowski said. “Eventually we want to develop equipment that better protects the brain in parallel with understanding actual brain cell damage baselines.”

He noted that there is currently no firm cellular injury threshold established for TBI cause or prediction.

The PANTHER program continues to investigate what brain cells can withstand and further refine testing models to improve protection standards. ONR has approved continued funding for PANTHER through 2024.