The German and Dutch armed forces have contracted with Rheinmetall to supply up to 3,058 Caracal airmobile platforms. Worth up €1.9 billion, the multiyear framework contract includes up to 2,054 vehicles earmarked for Germany and 1,004 for the Netherlands. As a first step, a firm order from the framework contract has been placed for 1,508 vehicles worth approximately €870 million, including value added tax. To finance the procurement project, Germany is drawing on the special fund set up last year for reequipping the Bundeswehr.

The Caracal is the product of a partnership between Rheinmetall, Mercedes-Benz AG and Armoured Car Systems GmbH. Delivery of the first trial models is scheduled to take place as early as the first quarter of 2024, with the start of delivery in series planned for early 2025.

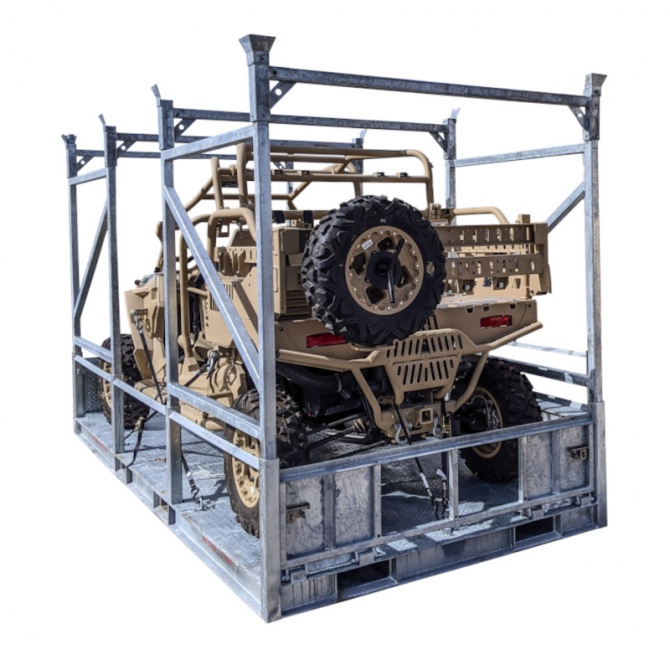

A 4×4 all-wheel-drive vehicle, the Caracal is a mobile platform specially designed to meet the needs of airmobile formations and special operations forces.

Procurement of the “Deployment System Airmobile Platform” is unfolding against the backdrop of the tense security situation and urgently required new capabilities for national and alliance defence. Owing to the close working relationship between the German and Dutch armed forces and the comparable requirement situation in both countries, the procurement project has been a bilateral one from the outset.

The tendering process, which began in October 2022, was completed in two fast-paced proposal phases. In the end, Rheinmetall put forward the most economical proposal, with price and technical performance converging to overcome the remaining competitor.

The Caracal is based on a commercial off-the-shelf chassis of the new G-model 464 series from Mercedes-Benz. In future Rheinmetall will therefore be able to offer users around the world a proven, technically mature platform, providing logistic support throughout the vehicle’s long service life.

With the Caracal, Rheinmetall’s portfolio of tactical vehicle systems has expanded to embrace the lightweight, less-than-10-ton 4×4 segment, where the Düsseldorf-based tech enterprise sees strong growth potential.

“Together with our partners Mercedes-Benz AG and Armoured Car Systems GmbH, we’re ready to roll and can advance quickly to full-scale, large-volume series production”, states Dr Björn Bernhard, managing director of Rheinmetall Landsysteme GmbH. “Final assembly of all German and Dutch vehicles will take place at our plant in Ede in the Netherlands and at VDL Special Vehicles B.V. in Eindhoven, our designated partner company. Having two assembly locations will let us quickly scale up production while simultaneously contributing to sustained value added in the Netherlands, our partner country”, notes Dr Bernhard.