GRAND RAPIDS, MICHIGAN (14 MAY, 2021)

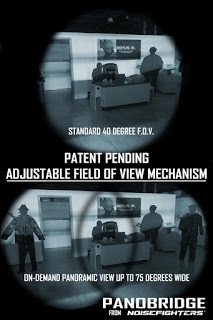

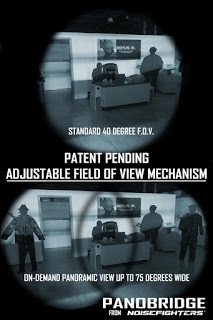

NOISEFIGHTERS and its development partner NIGHTLINE, INC., and its product testing partners GAMUT RESOLUTIONS and KINETIC CONSULTING, and its manufacturing partner MK MACHINING, and its distribution partners PRG DEFENSENITEWALKER, and TACTICAL NIGHT VISION COMPANY (TNVC) today announces the release of the patent pending PANOBRIDGE™ dual AN/PVS-14 night vision monocular bridge mount, which includes two industry-changing features: a total weight of only 1.5 oz / 42 g — or approximately 70% less weight than one of most popular competing AN/PVS-14 bridge mounts — and a proprietary mechanism that permits users to selectively adjust the goggle’s field of view from 40 to approximately 75 degrees by laterally rotating (or “panning”) each individual monocular outward to create a split image, which is then automatically merged in the user’s brain to form one cohesive, super-wide, panoramic image. By exploiting this new AFOV — or Adjustable Field of View — concept, the Panobridge eliminates the so-called tube effect experienced by night vision users and provides enhanced situational awareness. Whenever desired, the AFOV mechanism permits the tubes to be quickly pointed straight ahead, as currently provided with conventional binocular night vision goggles.

Photo representation inside Nightline, Inc.’s indoor training facility of the standard and split view panoramic image through dual AN/PVS-14 monoculars mounted on Panobridge

“There are millions of AN/PVS-14 monoculars in use worldwide, and many organizations and individuals are currently trying to find a way to extend and improve the working life and utility of these rugged, dependable night vision devices, ” said Neal Brace, owner of Noisefighters and inventor of the device. “Multi-tube night vision goggles provide much higher levels of immersion and depth perception by sending information to both eyes. Instead of purchasing new binocular or quad-tube night vision goggles, however, Panobridge presents a compelling, extremely inexpensive upgrade path for unmodified AN/PVS-14 monoculars to not only create a capable and lightweight dual-tube goggle, but also bring panoramic night vision viewing capabilities to the masses for the first time. While this product is not intended to replace quad-tube goggles for those specialized units which require them, I believe Panobridge provides a much more compact alternative, with a competitively wide field of view, at a price point which is accessible to all night vision users.”

Dual AN/PVS-14 monoculars with Nightline, Inc. NL914C lightweight digital battery housings installed, mounted to Noisefighters Panobridge in Cerakote® RAL8000 color

“By utilizing accessible AN/PVS-14 monoculars and requiring no extra hardware, the Panobridge allows organizations to continue the use of current night vision devices within a well-supplied and defined logistics network, eliminating the need for additional systems and training,” said Lee Collette, President of Nightline, Inc. “In addition, Nightline’s proprietary NL914C multi-battery housing further enhances the advantages of the Panobridge by creating a lighter weight, adjustable binocular with improved ergonomics, along with a wider, more natural field of view. At only 22.5 ounces or 638 grams assembled weight, with batteries included, this panoramic night vision system is a game-changing combination where two products come together to create an amazing synergy for the user.”

Dual AN/PVS-14 monoculars with Nightline, Inc. NL914C lightweight digital battery housings installed, mounted to Noisefighters Panobridge in Cerakote® Armor Black color, top view

During the development process, Mr. Brace sought feedback from some of the most experienced night vision users to ensure the Panobridge delivered an experience that matched or exceeded quad-tube goggle performance in four key areas: situational awareness, operational flexibility, overall weight and size, and price.

“What Noisefighters has managed to do with the Panobridge is incredible,” said the current owner of Gamut Resolutions training group, retired Master Sergeant Bob Keller, a ten year member of the U.S. Army 1st Special Forces Operational Detachment – Delta (Delta Force). “The fact that I can stow a lightweight, compact panoramic night vision goggle in my cargo pocket is game changing. The Panobridge presents the first worthwhile alternative to quad tube goggles that I’ve found. It is simple and tough, and by integrating standard AN/PVS-14 monoculars, it eliminates many logistical headaches.”

Exclusive product launch packaging with Noisefighters Panobridge in Cerakote® Armor Black color

Other reviewers with special operations experience found the Panobridge similarly appealing. “Most people and organizations can’t afford quad tube goggles. The Panobridge, coupled with two AN/PVS-14s, is the first alternative to quad tube goggles that I can now recommend for those looking for panoramic night vision,” said the current owner of Kinetic Consulting training group, Jon Dufresne, a former U.S. Army Ranger and current executive protection and law enforcement consultant who is additionally on staff with SAGE DYNAMICS.

Dual AN/PVS-14 monoculars with Nightline, Inc. NL914C lightweight digital battery housings installed, mounted to Panobridge in Cerakote® Armor Black color, front view

“The Panobridge is the best thing to happen to PVS-14 users in a very long time, with its extremely light weight and its wider field of view on demand,” said Will F., host of the popular Nitewalker night vision blog and video channel.

Night vision technology journalist Nick Chen provided a similarly concise summary of his findings: “The concept of the Panobridge is a clever trick and it does work. I was surprised how effective it is at giving you additional [field of view].” Mr. Chen’s review of the Panobridge is slated to be published 14 May, 2021 on The Firearm Blog, under the “Friday Night Lights” series of articles.

Other features of the Panobridge include:

-The ability to rotate the head slightly and peer through the gap between laterally-rotated (“panned out”) monoculars with an unaided eye in order to use a handheld thermal imager, aim pistol sights, glance at instrument panels, or view a scene using ambient light to better gauge distance, texture, color, or lighting. This is similar to the technique provided by using a single AN/PVS-14, but it is now available for multi-tube use.

Photo composite showing the use of a handheld thermal imager placed between laterally rotated (“panned out”) AN/PVS-14 monoculars and used directly in conjunction with Noisefighters Panobridge, courtesy of Nick Chen, journalist with The Firearm Blog.

-Both monoculars attached to the Panobridge may be individually swung upwards, completely out of the line of sight, without disturbing the adjacent device’s positioning. This feature also allows the PVS-14’s to better hug the helmet when the entire assembly is folded back in the stowed position, leading to a more balanced center of gravity and a reduced possibility of impacting door frames or other objects above the head.

-It is a nearly indestructible design utilizing an advanced, lightweight Arkema® polymer, all made possible by using the latest additive manufacturing techniques.

-The Panobridge will be available in extremely limited quantities as a launch exclusive in two Cerakote® ceramic finishes, Armor Black and RAL8000, and for general sale in flat black.

-The product is 100% manufactured and assembled in the U.S.A.

-The Panobridge is expected to retail between $500-700 depending on configuration.

In an effort to further exploit the Adjustable Field of View technology, Noisefighters and NOCTURN INDUSTRIES have agreed to collaborate and create a dedicated, lightweight binocular housing called the PANOBINO™ featuring the patent-pending AFOV mechanism and based on Nocturn Industries’ popular Katana™ Ultra-Light Articulating Night Vision Binocular. The companies expect a product launch later this year.

Concurrent with the development of the Panobridge, Mr. Brace developed a complementary product called the X14-Arm, which is a featherweight, single AN/PVS-14 night vision monocular mounting arm compatible with dovetail helmet mounts that tips the scales at only 0.7 oz / 20 g.

AN/PVS-14 monocular with Nightline, Inc. NL914C lightweight digital battery housing installed, mounted to X14-Arm in Cerakote® Armor Black color

“After getting positive feedback from those who evaluated the Panobridge, I recognized that individuals who use a single PVS-14 would likely benefit from the knowledge that we gained during the Panobridge development process,” said Mr. Brace. “The X14-Arm might just be the lightest night vision mounting arm ever released at only 0.7 ounces, yet it is very stiff for its weight due to the design, use of advanced polymers, and reliance on specialized manufacturing processes. If you only want to use one monocular, the X14-Arm is the ideal mounting solution.”

Exclusive product launch packaging with Noisefighters X14-Arm

Other features of the X14-Arm include:

-An intuitive, friction-based mechanism allows users to swing the PVS-14 monocular in front of either the left or right eye and perfectly adjust for interpupillary distance.

-It is a nearly indestructible design utilizing an advanced, lightweight Arkema® polymer, all made possible by using the latest additive manufacturing techniques.

-The product is 100% manufactured and assembled in the U.S.A.

-The X14-Arm is expected to retail between $100-150, depending on configuration.

Production of the polymer components for both the Panobridge and X14-Arm is being conducted by MK Machining, based in Hallsville, Missouri. MK Machining offers some of the most advanced additive manufacturing capabilities in the United States, with extensive experience from prototypes to production runs. In addition to their well-known throw levers and other additive-manufactured rifle accessories, MK Machining’s MK2 Bullpup Chassis radically transforms Remington 700 footprint rifles into a very compact precision rig with a surprisingly crisp trigger via an innovative linkage system.

CONTACT:

Noisefighters

www.noisefighters.com

team@noisefighters.com

616-226-3551

Grand Rapids, Michigan, U.S.A.

Nightline, Inc.

nightline-inc.com

info@nightline.us

423-727-5900

Mountain City, Tennessee, U.S.A.