PATTAYA, Thailand — The U.S. Air Force’s 15th Wing successfully supported a personnel drop operation while in an eight-ship formation on Mar. 3, 2023, during one of the largest multilateral theater security operation exercises in the Indo-Pacific.

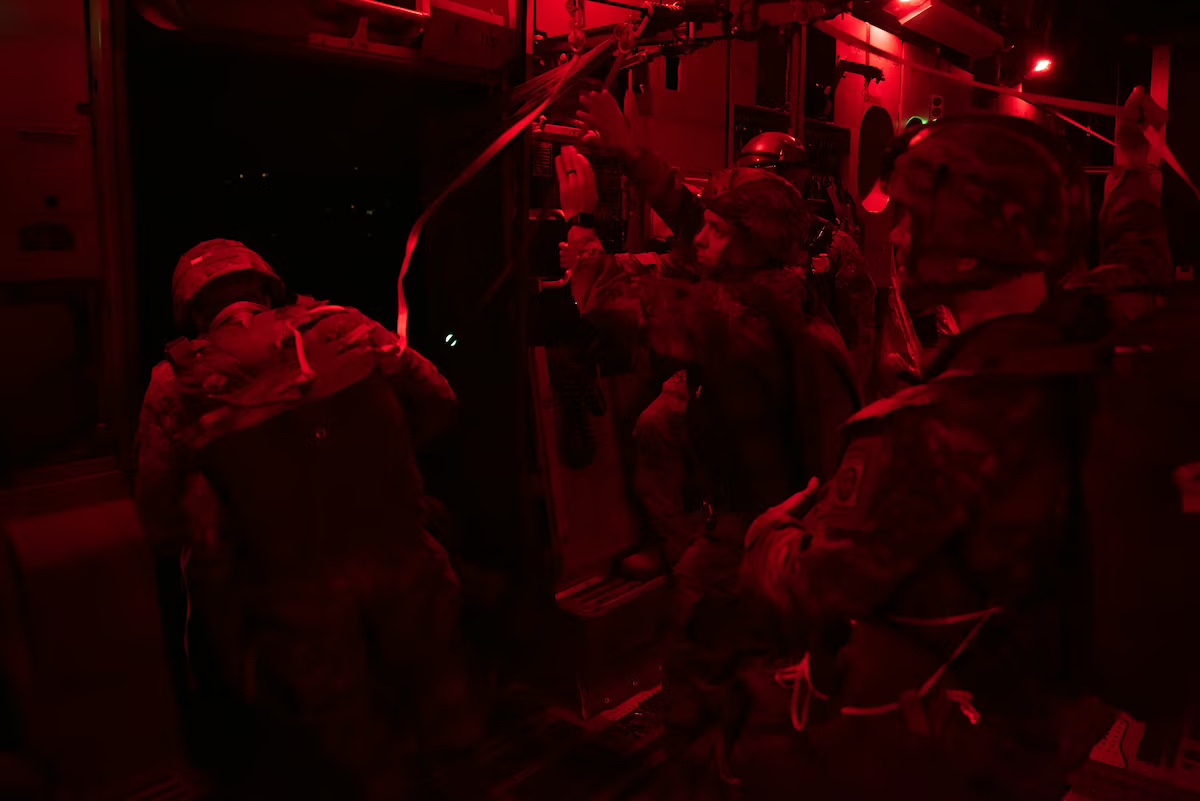

Operation planning took place on Diego Garcia, British Indian Ocean Territory, from Feb. 27 to Mar. 2, 2023, before dropping over a combined 600 U.S. Army 82nd Airborne Division and Royal Thai Army soldiers over the Kingdom of Thailand as part of Exercise Cobra Gold 2023.

U.S. Army Col. Todd Burroughs, commander, 2nd Brigade Combat Team, 82nd Airborne Division, mentioned that nearly 150 Thai soldiers were integrated to jump alongside the U.S. army.

“They are very proficient and they are ready to roll as part of Task Force Falcon,” said Burroughs.

To support the 82nd Airborne Division, aircrew assigned to the 535th Airlift Squadron and the 204th Airlift Squadron coordinated flight and personnel drop plans for the aerial operation, creating the majority of products needed for the event within two days.

“For an operation of this size, the planning timeline is typically nine months long,” said U.S. Air Force Maj. Mike Hank, 204th Airlift Squadron chief of tactics. “The Air Force planning team, in conjunction with the Air Mobility Division, accomplished this in 20 days.”

Of the eight C-17s that arrived on Diego Garcia, three were assigned to Joint Base Pearl Harbor-Hickam, Hawaii; two to Joint Base Charleston, South Carolina; and three to Joint Base Elmendorf-Richardson, Alaska.

“We’ve amassed seasoned pilots and loadmasters across all of our jets, and we have a robust maintenance team with participation from both the active duty, guard, U.S. Pacific Air Forces, Air Mobility Command, and integrated support from the Joint Communications Support Element and the AMD,” said Hank.

A joint mission brief was held the morning before the operation, highlighting important information needed for all participating parties, including weather conditions, aircraft rosters and drop zones.

“It’s in our DNA as air droppers — from joint forcible entry operations into Iraq in 2003 to the annual swift response exercises on our eastern flank — delivering the 82nd Airborne Division’s global response force concept is our bread and butter,” said Hank. “This time we get to conduct with the 82nd Airborne Division and our allies, the Royal Thai Army, always delivering our promise of anywhere, anytime and on time.”

Cobra Gold, now in its 42nd year, is a Thai-U.S. co-sponsored training event that builds on the long-standing friendship between the two allied nations and brings together a robust multinational force to promote regional peace and security in support of a free and open Indo-Pacific.

By SSgt Alan Ricker, U.S. Air Force