AUSTIN, Texas — Several thousand U.S., U.K. and Australian service members, researchers and industry partners will experiment with and assess new technologies at U.S. military installations across the Western U.S. between September and November as part of Project Convergence 2022.

The expansive effort is the newest endeavor of the U.S. Army’s Project Convergence, a flagship modernization learning, experimentation and demonstration campaign. The Army led its first large-scale Project Convergence experiment in 2020, and has continued to grow the scope, scale and complexity of the event annually.

“Project Convergence 2022 is an all-service experiment that includes Special Operations Forces, and our U.K. and Australian partners. Using existing and emerging technologies from space to land and sea, PC22 will experiment with capabilities that protect against air and missile threats as well as those that will allow us to defeat anti-access defenses,” said Lt. Gen. Scott McKean, director of Project Convergence 2022. McKean explained Project Convergence 2022 incorporates service experimentation and learning, like the Air Force’s Advanced Battle Management System and the Navy’s Project Overmatch, to inform Joint All-Domain Command and Control development. Logistics capabilities will also play a central role in PC22.

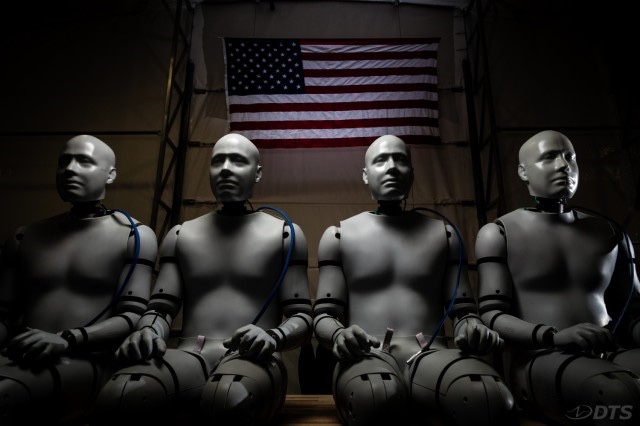

Project Convergence 2022 will evaluate approximately 300 technologies, including long-range fires, unmanned aerial systems, autonomous fighting vehicles and next-generation sensors, and focus on advancing Joint and Multinational interoperability in future operational environments.

The event will also encompass the inaugural PC22 Technology Gateway, an industry engagement opportunity hosted by U.S. Army Combat Capabilities Development Command that will kick off experimentation by assessing novel solutions available from the commercial sector.

“Having Tech Gateway as part of the Project Convergence series gives us the opportunity to assess new technologies against operational concepts and see what’s in the realm of the possible; what could be. Such experimentation informs possible future Army requirements, provides valuable feedback and increases the speed of learning as we strive for breakthrough technologies of the future,” said Lt. Gen. Thomas H. Todd III, deputy commanding general for Acquisition & Systems and the chief innovation officer at U.S. Army Futures Command.

The Joint Force and Multinational partners will utilize key learning and experimentation outcomes from Project Convergence 2022 to hone new military technologies, many of which offer state-of-the-art problem solving and network integration capabilities for the future fight.

By Army Futures Command

“We are extremely proud to have received this Phase II contract and are excited to continue developing this technology into a solution that enhances the performance of our pilots,” said Dennis Finnegan, President of EOTECH GOV. “EOTECH has been at the forefront of holography, dating back to the 1950’s, and has dedicated its existence to providing tools and technology that improve the performance and increase the safety of our warfighters.”

“We are extremely proud to have received this Phase II contract and are excited to continue developing this technology into a solution that enhances the performance of our pilots,” said Dennis Finnegan, President of EOTECH GOV. “EOTECH has been at the forefront of holography, dating back to the 1950’s, and has dedicated its existence to providing tools and technology that improve the performance and increase the safety of our warfighters.”