Marine Corps Base Quantico, Va. —

As the Marine Corps prepares to take the fight to the global littorals, Marine Corps Systems Command’s Program Manager for Explosive Hazard Defeat’s Littoral Explosive Ordnance Neutralization—LEON–integrated product team is working on fielding a family of systems to strengthen Marine Corps mine warfare capabilities.

Designed to address the concerns outlined in the Littoral Operations in a Contested Environment guidance, these systems fortify Marines’ mine warfare capabilities as the Corps continues with the strategic modernization outlined in former Commandant of the Marine Corps, Gen. David H. Berger’s seminal Force Design guidance.

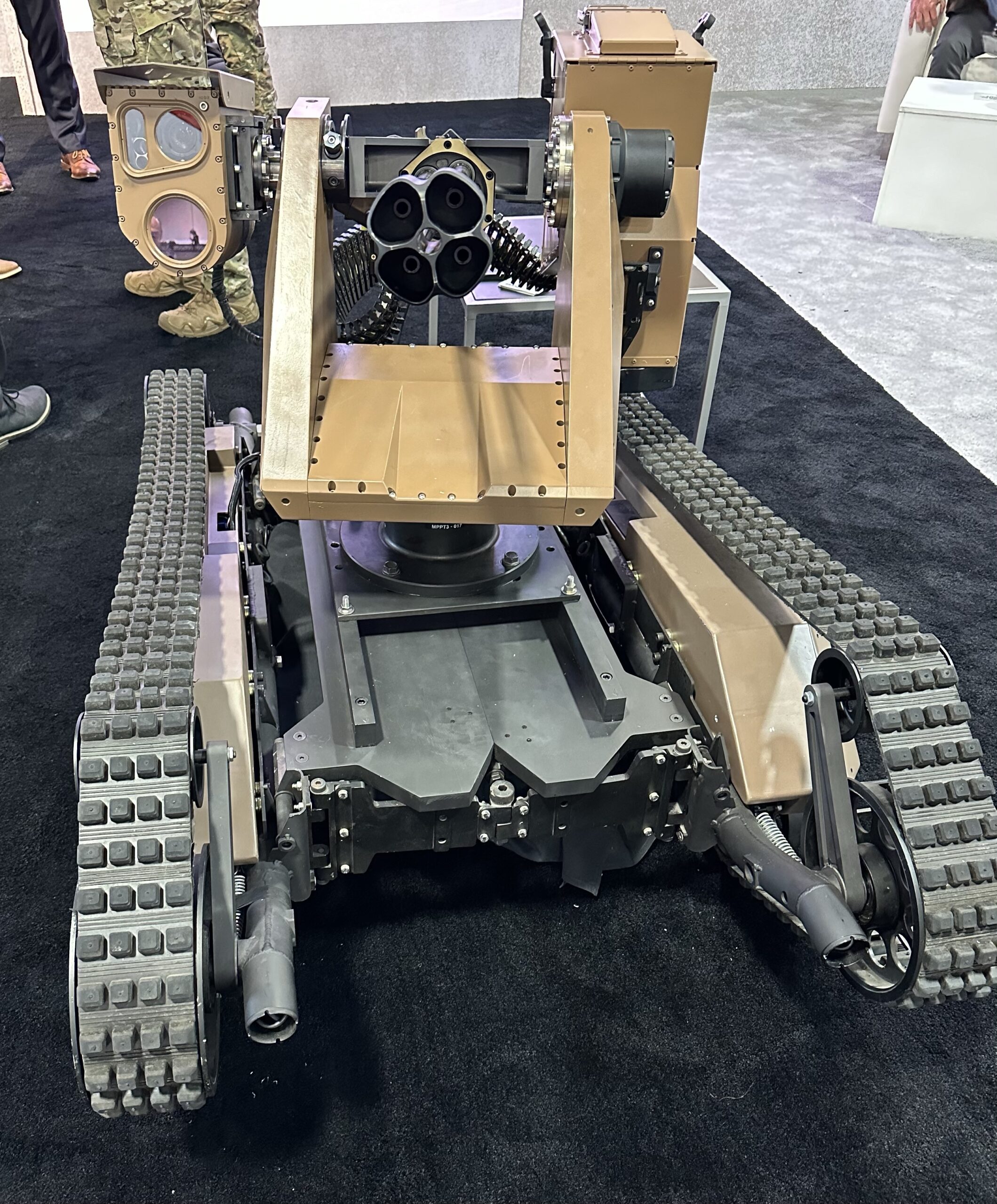

The LEON family of systems encompasses various capabilities, among which the Explosive Ordnance Disposal Remotely Operated Vehicle—or ROV—stands out as an integral component. This innovative amphibious, unmanned robot system is specifically designed to detect, locate, reacquire, mark to avoid, render safe/neutralize, recover, exploit, and dispose of underwater explosive threats in the very shallow water, surf zone, beach zone and littoral transition points.

This bleeding-edge robotic technology—along with its integrated family of capabilities—strives to secure safe maneuverability for Marines within the littoral regions, extending support to the explosive ordnance disposal community and enhancing the overall service proficiency.

According to Product Manager for Explosive Hazard Defeat Rick Daley, LEON is a tool which will allow the support of ship-to-shore and shore-to-ship lane clearing operations more safely and effectively.

“If we aim to conduct operations as part of a MAGTF or drug task force, it necessitates a World War II style island-hopping campaign, requiring safe access to the islands. Our adversaries will be trying to stop us, though. With the advent of the LEON initiative, the strategy shifts to ‘tech to avoid’—identifying safe lanes through minefields and enabling forces to securely land on the beaches,” he said.

This innovative new system ultimately aligns with Force Design’s modernization guidance, which calls on the Corps to, “acknowledge the impacts of proliferated precision long-range fires, mines, and other smart weapons, and seek innovative ways to overcome these threat capabilities.”

The LEON team has certainly taken the call to innovate seriously. A notable facet of the team’s strength is its proactive stance towards embracing emergent technologies, thereby fostering state-of-the-art solutions tailored for the complexities of 21st-century naval warfare.

This forward-thinking approach not only underscores their commitment to enhancing maritime operational efficacy but also positions them at the vanguard of navigating the multifaceted challenges inherent in contemporary littoral combat scenarios.

According to Daley, “It’s imperative to note that unlike many unmanned capabilities, such as drones, our systems operate fully submerged. Until the acoustic communications are fully online, direct communication isn’t necessarily possible. Therefore, there’s a need for either pre-programming or having advanced software programming to enable complete autonomous operation. This allows the system to execute the required tasks and then return to a recoverable location, which is crucial. Without such measures, we’re merely deploying assets with the hope that they fulfill the intended objectives.”

“If we aim to conduct operations as part of a MAGTF or drug task force, it necessitates a World War II style island-hopping campaign, requiring safe access to the islands. Our adversaries will be trying to stop us, though. With the advent of the LEON initiative, the strategy shifts to ‘tech to avoid’—identifying safe lanes through minefields and enabling forces to securely land on the beaches,”

-Rick Daley, Product Manager for Explosive Hazard Defeat

One of the ways that the LEON team has been able to gain so much success here is through the fostering of untraditional partnerships across the Corps’ – with a special focus on direct feedback from the fleet. According to Ronald Diefenbach, LEON project officer, this has made all of the difference.

He noted, “Our collaboration with [Naval Information Warfare Center] Pacific has been pivotal in refining our platforms. Furthermore, we had the advantage of having a Marine from I Marine Expeditionary Force, I MEF, embedded with NIWC Pacific from the program’s outset, providing real-time feedback during the development process. This setup significantly bridged any communication gap, ensuring our technological advancements are aligned with practical operational needs from the very beginning of the development stage.”

Similarly, Diefenbach noted how always picking the right contract vehicle for specific parts of the project helps save time—and ultimately—taxpayer dollars. And with the LEON team moving so quickly, the future of the program certainly looks bright.

This was exemplified in a 2021 exercise when Marines from I and III MEF conducted a littoral mobility exercise, showcasing how this bleeding-edge tech can be utilized in joint-force operations with the Navy.

The collaboration between the 9th Engineer Support Battalion, 3d Marine Logistics Group, 7th ESB, 1st MLG and U.S. Navy Explosive Ordnance Disposal Mobile Unit 1 ultimately demonstrated the seamless integration of diverse capabilities to establish secure beachheads for amphibious operations.

The exercise highlighted the pivotal role of integrated capabilities in supporting naval maneuver, aligning with the tenets of Force Design 2030 to enhance real-time situational awareness and expedite decision-making in amphibious environments.

At the time, 1st Lt. Brandon Cavil, who then served as Littoral Engineer Reconnaissance Team officer in charge, noted the “exercise was all about honing the Marine Corps’ interoperability with the Navy, specifically addressing where we can provide redundant and complementary capabilities.”

Ultimately, the success of the LEON team is a testament to the foresight of the 2017 Littoral Operations in a Contested Environment document and underscores the growing importance of naval mine warfare as the Corps continues its strategic shift towards the Indo-Pacific.

This important advance in maritime technology has not gone unnoticed. In recognition for their efforts, the LEON Integrated Product Team received the Department of the Navy’s 2023 Ron Kiss Maritime Technology Transition Award, which honors outstanding achievement in the defense acquisition community for successfully transitioning a technology into a program of record or operational use.

By transcending traditional paradigms and fostering a culture of innovation and adaptability, Product Manager Explosive Hazard Defeat is not only responding to the shifting needs of the modern battlefield—it’s actively influencing the future of naval warfare. As the Marine Corps continues its strategic shift to the Indo-Pacific– guided by Force Design– the robotic technology that is being developed by the LEON team will play a vital role in navigating the dynamic and complex global littorals—ensuring the warfighter is prepared to fight and win when duty calls.

By Johannes Schmidt, Marine Corps Systems Command Office of Public Affairs and Communication | Marine Corps Systems Command